An electromagnetic suture tension adjustment device

A tension adjustment, electromagnetic coil technology, applied in tension devices, sewing equipment, sewing machine components, etc., can solve problems such as loss, inconvenient adjustment, defectiveness, etc., to reduce the probability of emergencies, and automatically adjust the thread tension. , the effect of buffer adjustment force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

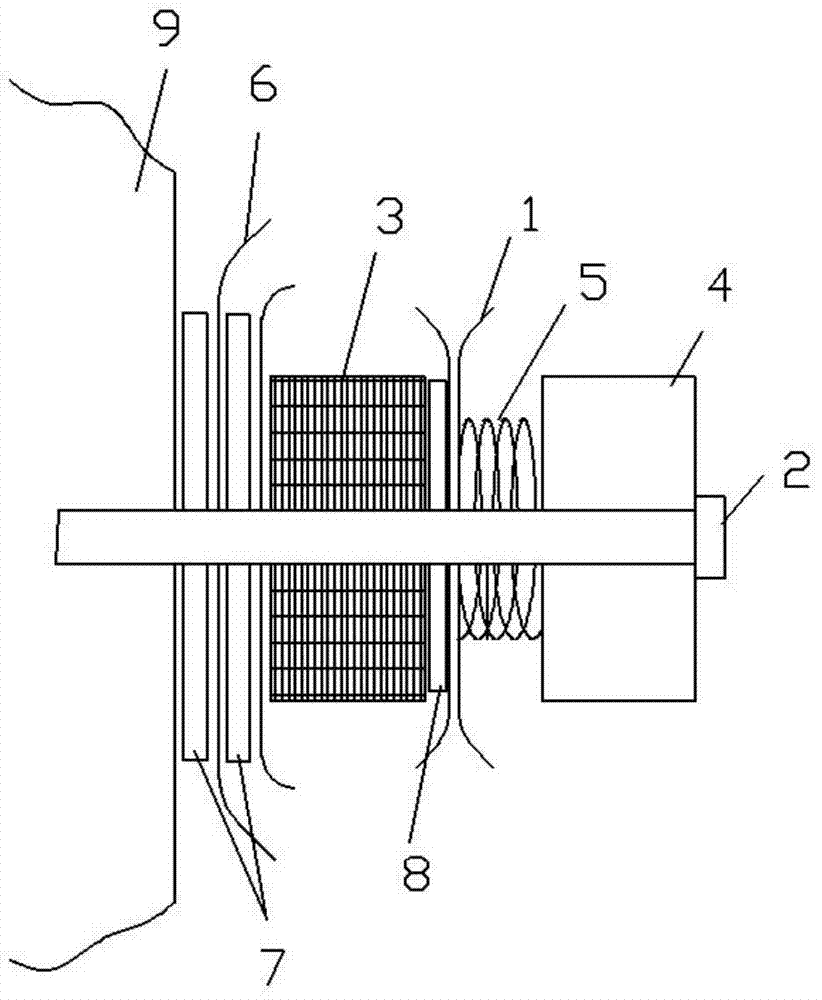

[0017] Such as figure 1 As shown, an electromagnetic suture tension adjustment device includes a thread tension disc 1 and a mounting screw 2, and is characterized in that it also includes an electromagnetic coil 3 and an armature 4, and the electromagnetic coil 3 and the armature 4 are respectively arranged on the sides of the thread tension disc 1. On one side, the mounting screw 2 is fixed on the head 9 of the sewing machine through the electromagnetic coil 3, the armature 4 and the tension disc 1. By using the clamping structure of the electromagnetic coil 3 and the armature 4, it is convenient to adjust the thrust of the clamping disc 1. In actual use, the current intensity flowing through the electromagnetic coil 3 can be adjusted through the preset program in the system. Make adjustments to achieve the effect of automatically adjusting the suture tension.

[0018] The electromagnetic coil 3 is arranged near the head 9 of the sewing machine, and the armature 4 is arrang...

Embodiment 2

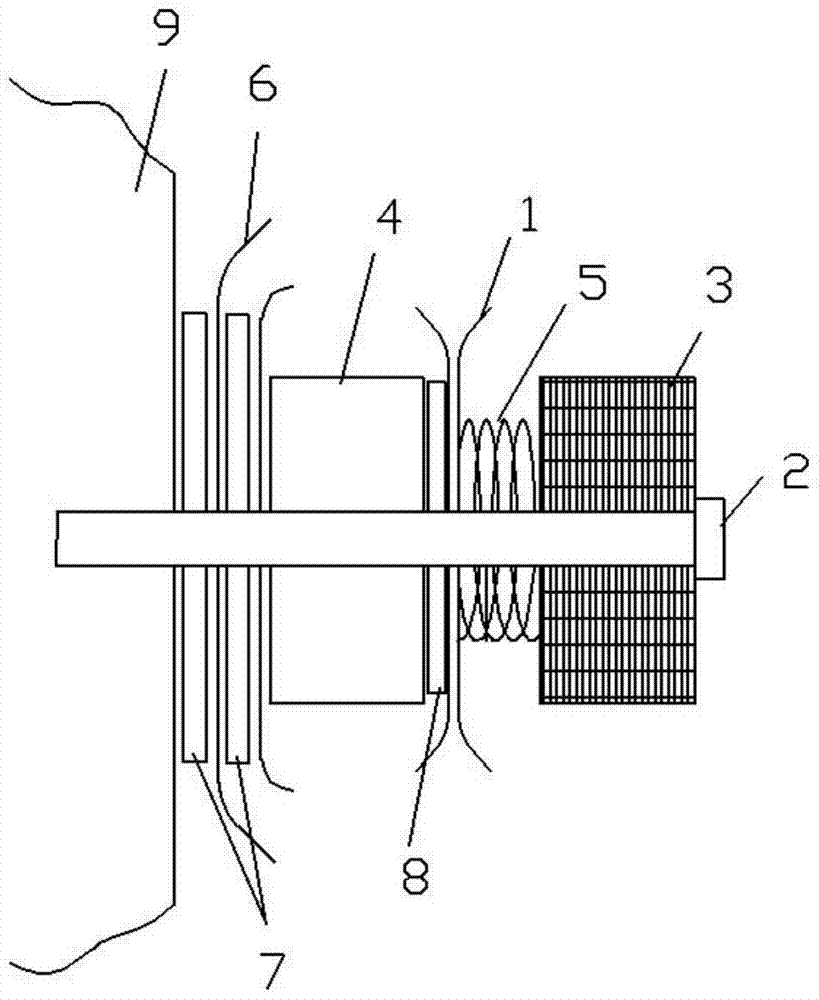

[0025] Such as figure 2 As shown, an electromagnetic suture tension adjustment device includes a thread tension disc 1 and a mounting screw 2, and is characterized in that it also includes an electromagnetic coil 3 and an armature 4, and the electromagnetic coil 3 and the armature 4 are respectively arranged on the sides of the thread tension disc 1. On one side, the mounting screw 2 is fixed on the head 9 of the sewing machine through the electromagnetic coil 3, the armature 4 and the tension disc 1. By using the clamping structure of the electromagnetic coil 3 and the armature 4, it is convenient to adjust the thrust of the clamping disc 1. In actual use, the current intensity flowing through the electromagnetic coil 3 can be adjusted through the preset program in the system. Make adjustments to achieve the effect of automatically adjusting the suture tension.

[0026] The armature 4 is arranged near the head 9 of the sewing machine, and the electromagnetic coil 3 is arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com