Forklift for disassembling automobile

A car dismantling and forklift technology, applied in the direction of lifting devices, etc., can solve problems such as unsatisfactory dismantling, and achieve the effect of improving the scope and purpose of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

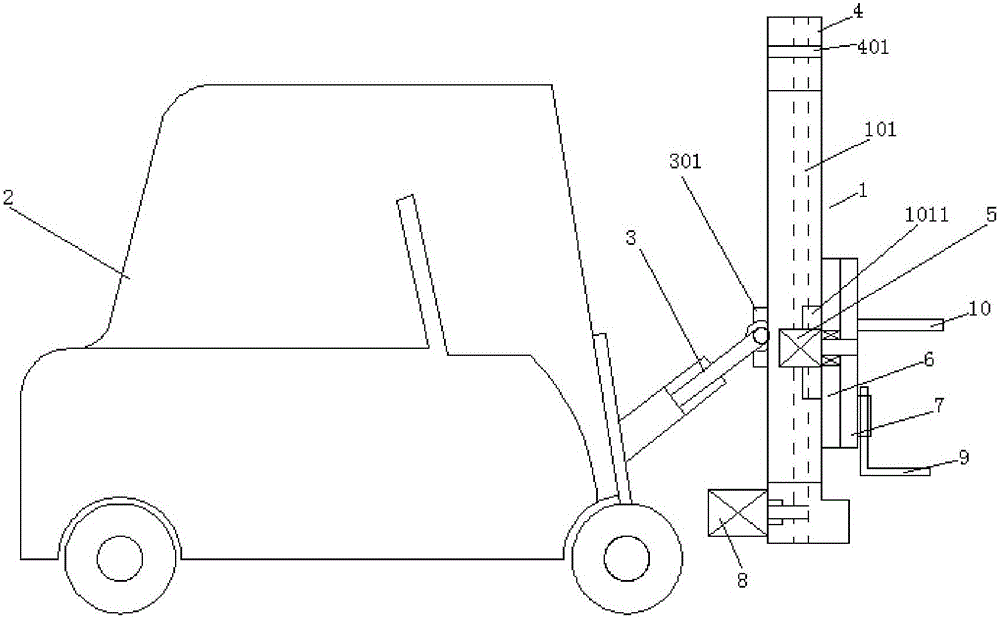

[0012] Referring to the accompanying drawings, a forklift used for dismantling automobiles includes a vehicle body 2 and a material-receiving fixed frame 1. The material-receiving fixed frame 1 is arranged on the front side of the vehicle, and hydraulic telescopic support columns 3 are provided on both sides of the front end of the vehicle body 2. The front end of the telescopic support column 3 is hingedly connected with the material-receiving fixed frame 1 through a hinge connector 301. The first closed transmission chain 101 is provided on the described material-receiving fixed frame 1. The upper and lower ends of the transmission chain 101 are respectively provided with transmission gears 4, and the transmission The gear 4 is fixed on the receiving fixed frame 1 through the fixed shaft 401, the driving device 5 is connected on the fixed shaft of the lower transmission gear, the transmission chain 101 is provided with a fixed crossbeam 1011, and the fixed crossbeam 1011 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com