A heat-sealable sealing device

A sealing device and heat-sealing technology, which is applied in the direction of packaging, capping, and closures, can solve the problems of poor sealing between the upper cover and the lower tube, too tight fit between the upper cover and the lower tube, and a small range of screwing angles. Achieve the effect of fast capping speed, high production cost and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

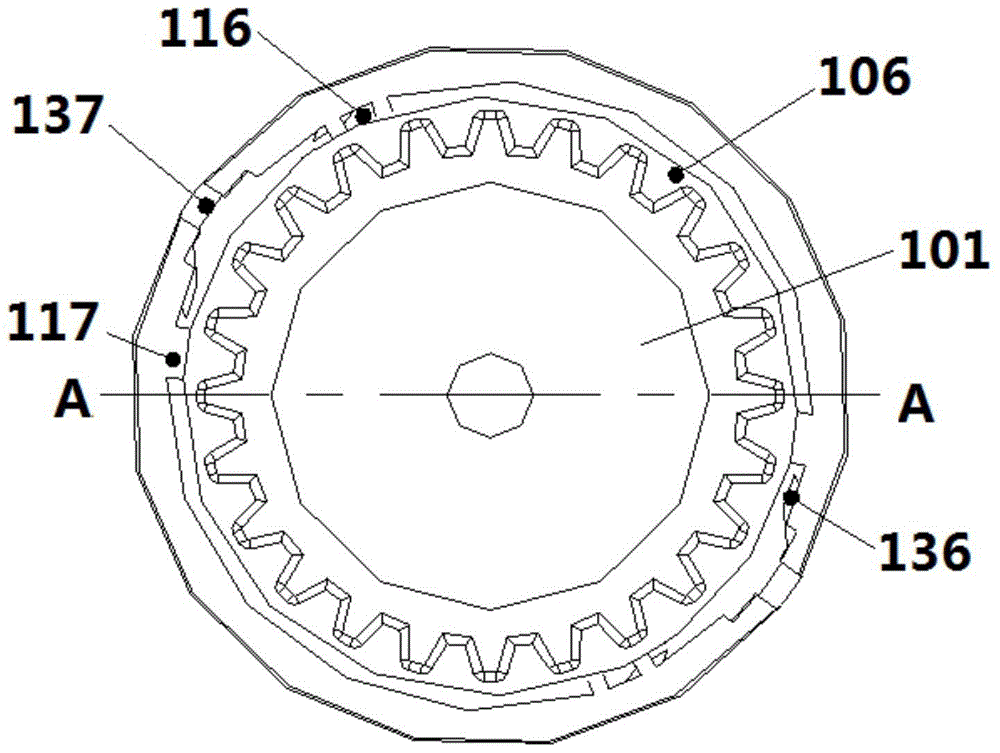

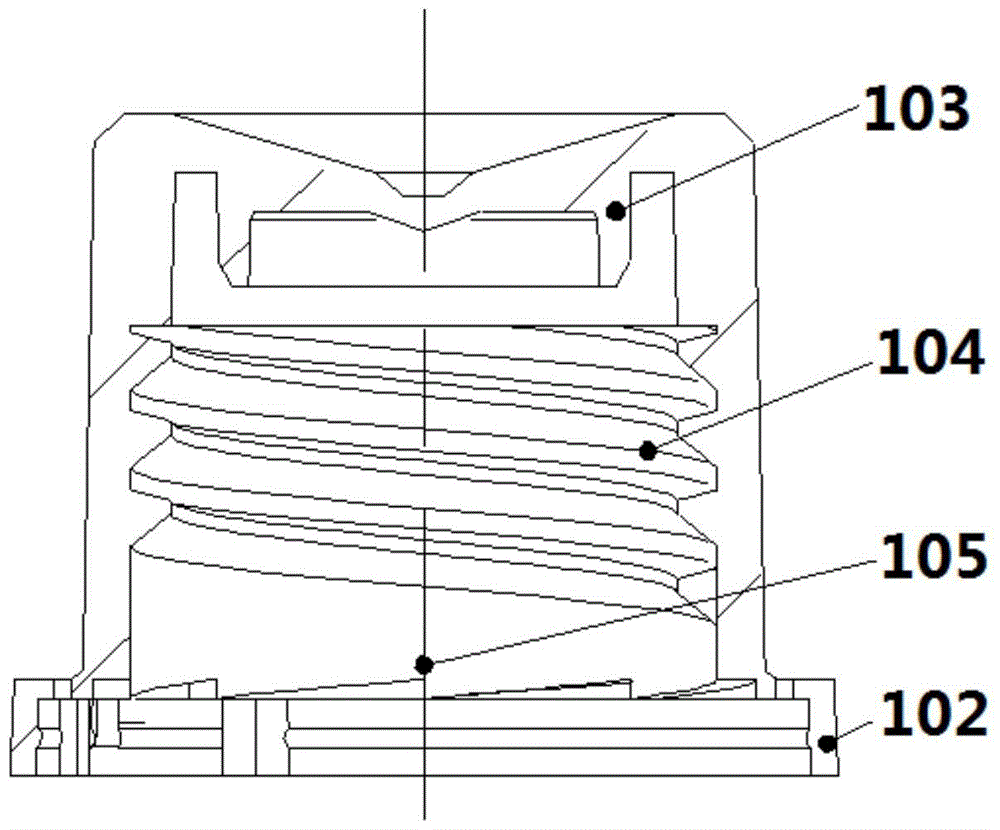

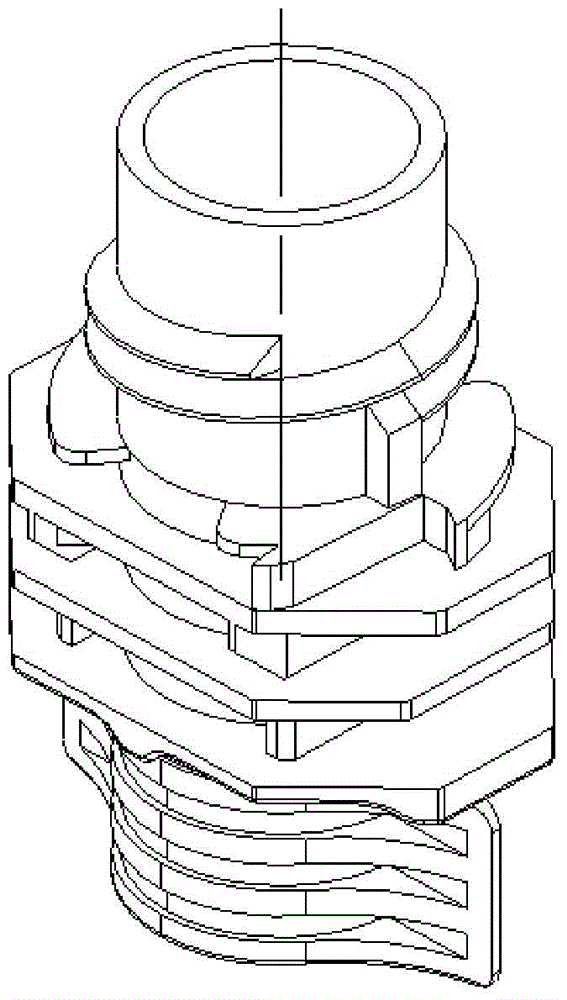

[0044] The sealing device of flexible packaging includes an upper cover and a lower tube that cooperate with each other. In the current flexible packaging, there is a problem that the seal between the two is not tight or the screw is too tight, mainly because the plastic product itself has plastic deformation. , the corresponding filling temperature varies greatly, especially for products that require high-temperature filling or high-temperature sterilization. If the force of screwing the upper cover is too small, the seal between the upper cover and the lower tube will not be tight, and it will easily leak after high temperature deformation; if the force of the upper cover is too large, the gap between the upper cover and the lower tube will The fit is too tight, difficult to open, etc. Due to the narrow range of the most suitable screwing force and screwing angle, the above-mentioned problems inevitably occur in the sealing device.

[0045]In order to improve the above prob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com