Method for comprehensively extracting fucoxanthin and brown alga polyphenol from gulfweed

A technology for brown algae polyphenols and fucoxanthin, which is applied in the directions of organic chemistry, color/spectral property measurement, etc., can solve the problems of inability to realize technology popularization and large-scale production, low extraction efficiency and raw material utilization rate, and high production cost, Achieve the effect of low cost, small difference and product safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

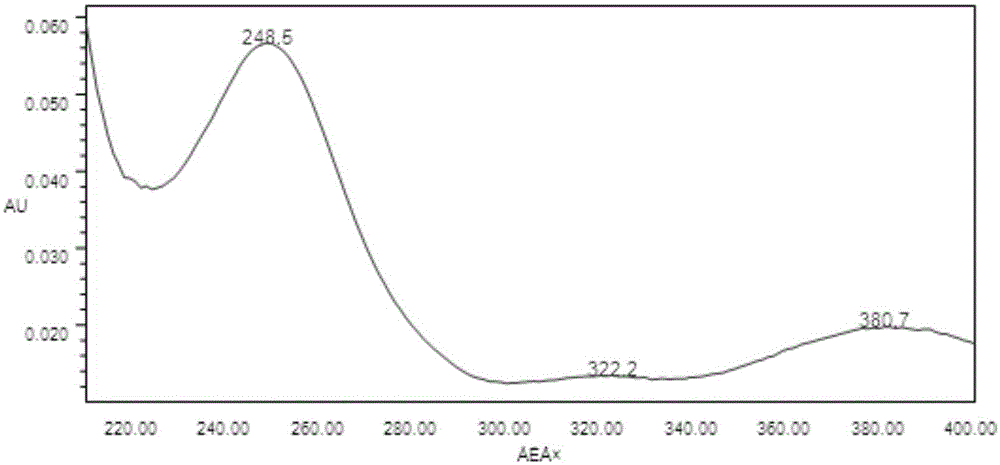

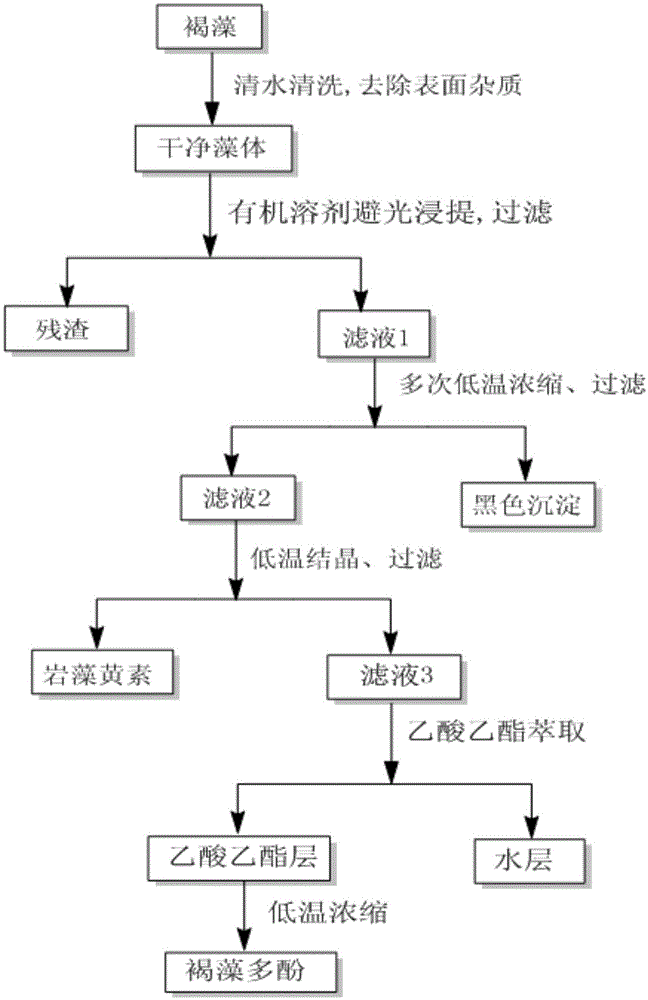

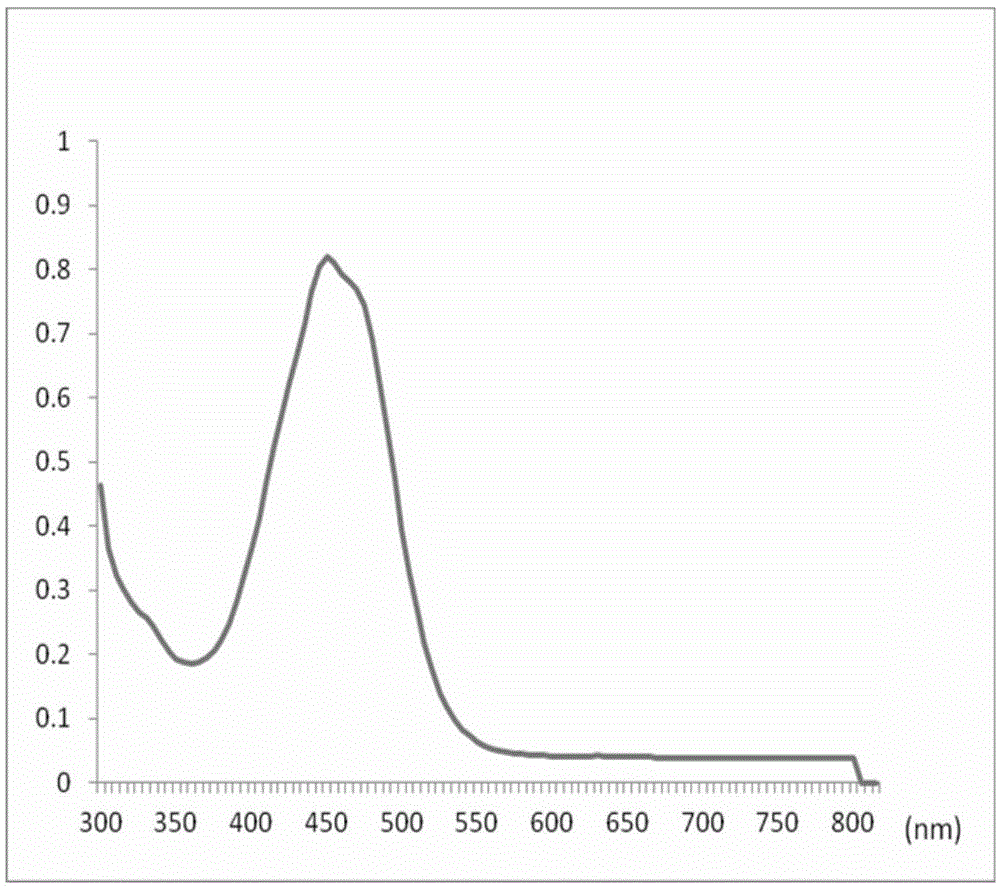

[0047] process such as figure 1 As shown, the fresh copper algae was frozen at -40°C, taken out after freezing for 15 days, and air thawed at room temperature until the central temperature of the copper algae reached 1°C. into a centrifuge, and centrifuged at 800rpm for 10 minutes to remove water; through repeated freezing and thawing and centrifugation 3 times, the water content of copper algae was controlled to 90%. Weigh 100g of copper algae into a 1000mL conical beaker, add 500mL of 85% (V / V) ethanol aqueous solution, seal the mouth of the conical beaker with a safety film, extract for 1 hour in the dark, and filter. Continue to add 500mL of 85% (V / V) ethanol aqueous solution to the copper algae that has been leached above, seal the mouth of the triangular beaker with a safety film, leaching for 1 hour in the dark, and filter. Repeatedly leached in the dark until the extract was colorless, and the filtrates were combined. Concentrate the above-mentioned filtrate at 40°C....

Embodiment 2

[0050] Freeze the fresh hijiki at -5°C, take it out after freezing for 30 days, and thaw it in the air at room temperature until the center temperature of the hijiki reaches 2°C to complete the freeze-thaw process; put the hijiki Put it into a centrifuge, and remove water by centrifugation at a speed of 10000rpm for 3 minutes; through repeated freezing and thawing and centrifugation for 5 times, the moisture content of Hijiki is controlled to be 58%. Weigh 100g of Hijiki and put it into a 1000mL triangular beaker, add 300mL of 85% (V / V) ethanol aqueous solution, seal the mouth of the triangular beaker with a safety film, leaching for 1 hour in the dark, and filter. Continue to add 300mL of 85% (V / V) ethanol aqueous solution to the above-mentioned copper algae, seal the mouth of the triangular beaker with a safety film, leaching for 1 hour in the dark, filter, and combine the filtrates. Concentrate the filtrate at 40°C. During concentration, when a large amount of precipitation...

Embodiment 3

[0053] Same as the above example 1, the difference is that the fresh copper algae is frozen at -80°C, taken out after freezing for 1 day, and air thawed at room temperature until the central temperature of the copper algae reaches 0°C. Thawing process: put the copper algae into the centrifuge, and centrifuge at a speed of 5000rpm for 5 minutes to remove water; through repeated freezing and thawing and centrifugation for 5 times, the water content of the copper algae is controlled to 50%; the extraction time in the dark is 3 hours; The temperature of low-temperature concentration is 15°C; the organic reagent is acetone; the ratio of copper algae to organic reagent is 100g: 400ml.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com