Large rolling shaft seal welding tool

A technology for welding tooling and rollers, which is used in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The content of the present invention will be described below in conjunction with specific embodiments.

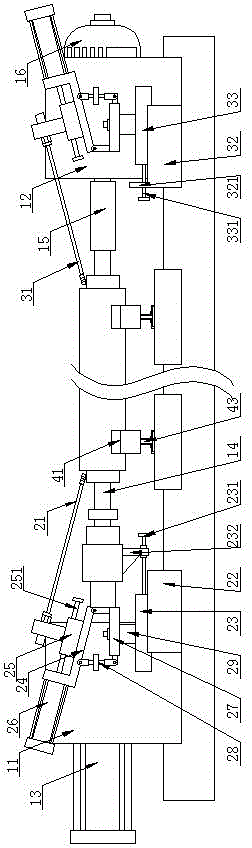

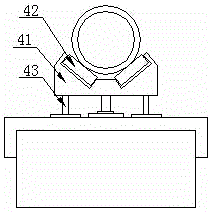

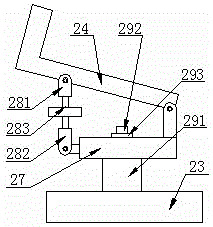

[0024] Such as Figure 1 to Figure 3 As shown, it is a structural schematic diagram of a large-scale roller sealing welding tool according to the present invention. A large-scale roller sealing welding tool according to the present invention includes: a clamping and rotating mechanism for clamping and rotating the roller, and a first welding mechanism and a second welding mechanism respectively used for welding the two ends of the roller; The idler mechanism at the bottom of the roller, the idler mechanism includes an idler seat 41 and two idler rollers 42 arranged on the idler seat 41, the axes of the two idler rollers 42 are perpendicular to the roller shaft axis, and the two idler rollers 42 are distributed in a V-shaped structure; the bottom of the idler seat 41 is provided with a height adjustment screw 43 .

[0025] The clamping rotation mechanism includes a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com