Bending equipment for sheet metal

A technology of plate and equipment, applied in the field of bending equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

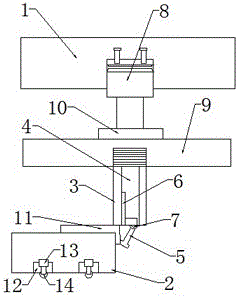

[0018] Bending equipment suitable for plates, including: upper die base 1, lower die base 2 for placing products, driving parts connected to upper die base 1, bending punches 3 connected to driving parts, and bending punches 3 The first installation groove 4 inside, the fine-tuning bending assembly set in the first installation groove 4, the mobile assembly placed at the bottom of the lower mold base 2, the fine-tuning bending assembly includes: a guide rail 6 placed on the inner wall of the first installation groove 4 , is connected to the pendulum punch 5 of the moving part, and is connected to the rotating part between the moving part and the pendulum punch 5 . As a preference, the rotating member is an electronic rotating shaft 7 . In order to allow the fine-tuning bending assembly to accurately act on the preset product position, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com