Clutch lock

A clutch lock and clutch pin technology, which is applied in the field of clutch locks, can solve problems such as the lock cannot be opened, the clutch pin cannot be realized, and the rear lock cylinder cannot be driven, so as to improve reliability and solve the effect of not being able to unlock the lock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

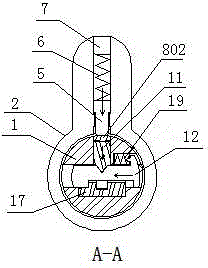

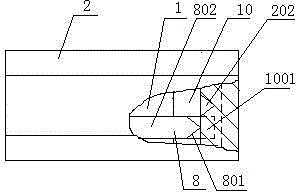

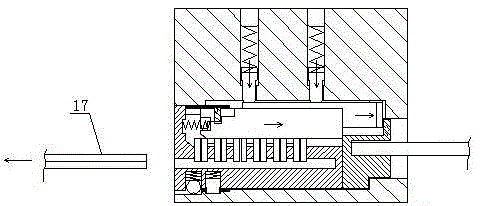

[0015] See figure 1 — image 3 , the clutch lock of the present invention includes a lock body 2, a rotatable lock core 1 and a clutch seat 10 are arranged axially in the lock body 2, and a number of two blade pins 12 and their return positions are arranged on the lock core 1 along the axis. The spring 19 is a set of blade pins, and the blade pins 12 are provided with V-shaped grooves; the lock core 1 and the clutch seat 10 are respectively provided with corresponding locking side column grooves 101 and clutch pin slide grooves 1001, and the locking side column grooves 101 and the clutch pin chute 1001 are respectively provided with a locking side column 11 and a clutch pin 8 with a handle 802. The locking side column 11 can be matched with the V-shaped groove on the blade pin 12, and the locking side column 11 is provided with a step shaped groove 1101, the upper part of the locking side column groove 101 is fixed with the card 4 that matches the stepped groove 1101 on the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com