Process system for improving dust removal, desulfurization and demercuration efficiency of boiler flue gas

A process system, boiler flue gas technology, applied in the direction of dehydration/drying/concentrated sludge treatment, use of liquid separation agent, chemical instruments and methods, etc., can solve the problems of large amount of sewage, large water consumption, high operating costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

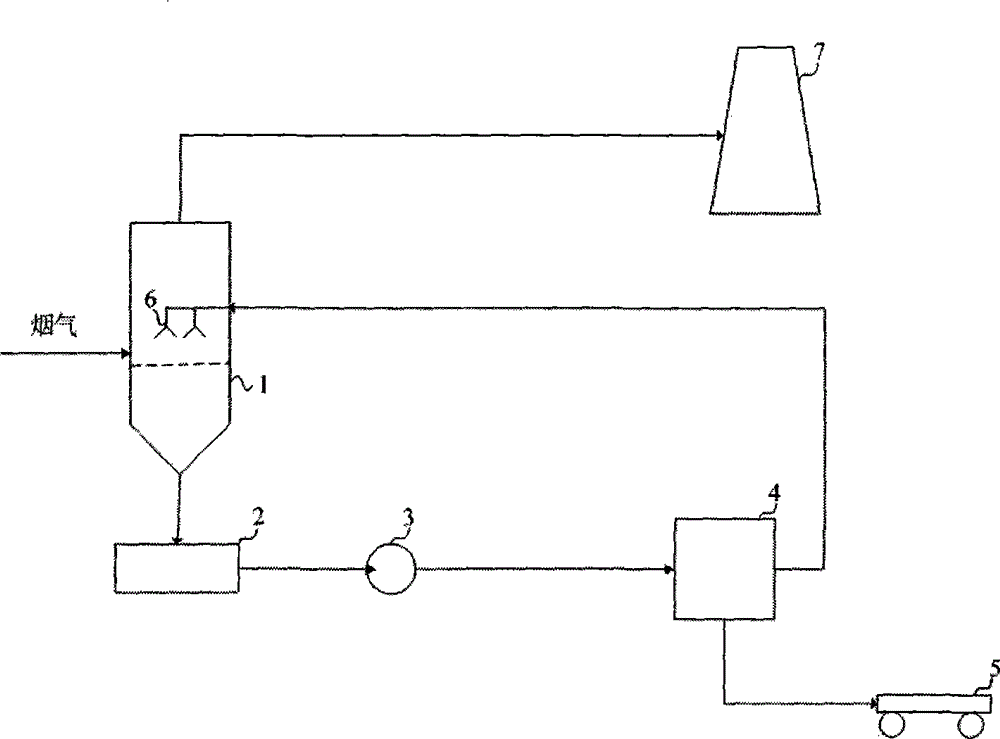

[0009] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

[0010] The present invention is a process system for improving boiler flue gas dedusting, desulfurization and mercury removal efficiency and water utilization, which includes the following content: high-efficiency wet dust collector or desulfurization tower (1), flocculation tank (2), sewage pump (3), high-efficiency Sewage treatment and concentrator (4), dehydrator (5), sprinkler (6), chimney (7);

[0011] Its technological process is as follows:

[0012] 1. The boiler flue gas enters the high-efficiency wet dust collector or desulfurization tower (1), and the flue gas after dust removal and desulfurization directly enters the chimney (7) and is discharged up to the standard;

[0013] 2. The dusty and gypsum sewage from the high-efficiency wet dust collector or desulfurization tower (1) enters the flocculation tank (2) enters the high-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com