Channel slope lining troweling equipment with pre-pressing and bulldozing effects

A pre-pressure and channel technology, applied in artificial waterways, water conservancy projects, construction, etc., can solve problems such as labor-intensive, high labor intensity, and inability to guarantee the main truss track tread, and achieve the effect of reducing labor costs and labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The specific embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

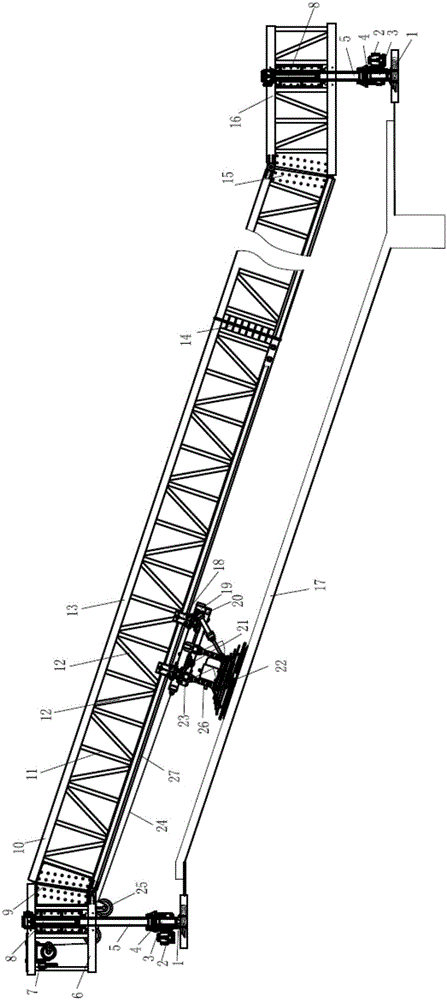

[0035] Such as figure 1 As shown, it is specifically described that a channel slope lining and troweling equipment provided by the present invention has a preloading and pushing effect, and includes a main truss 10 arranged parallel to the channel slope, and the two ends of the main truss 10 are respectively connected to the The first connecting portion 9 of the first mounting frame 6 is connected to the third connecting portion 15 of the second mounting frame 16, and the first mounting frame 6 and the second mounting frame 16 all include slide rails 1 arranged on the machine base, The slide rail 1 is matched and connected with the roller 3 arranged on the walking bottom beam 4, and the walking bottom beam 4 is provided with a leg 5 connected with the screw nut lifting mechanism 8, and the lower beam of the main truss 10 And cross...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com