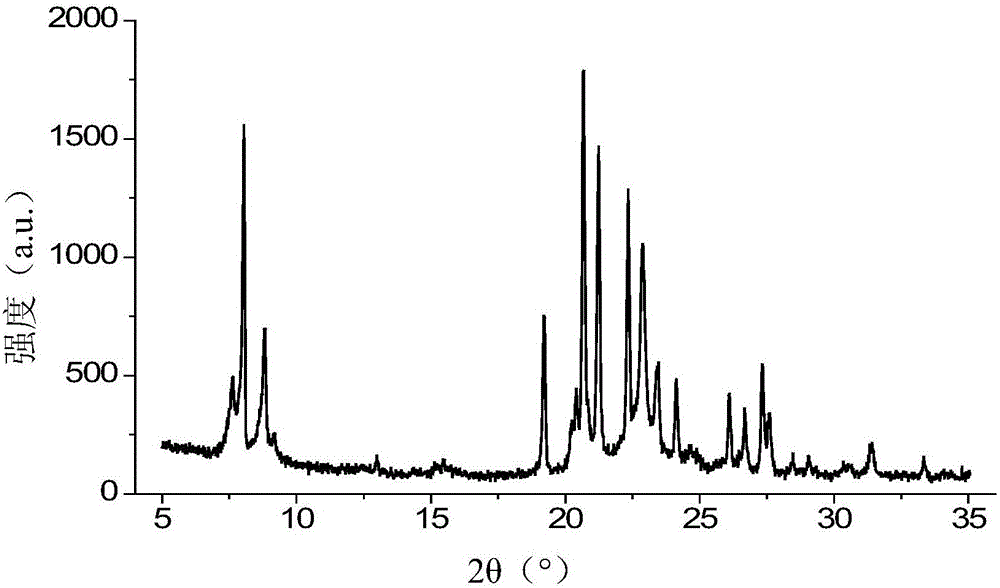

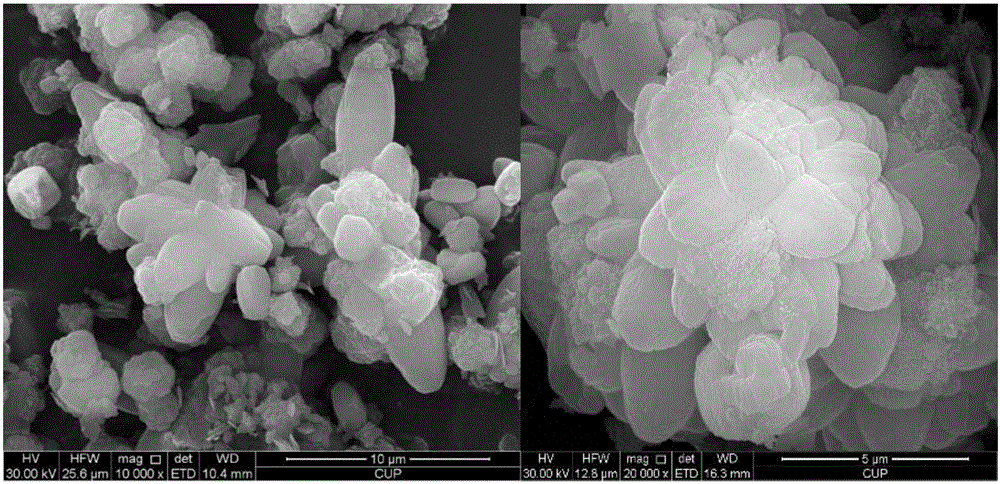

EU-1/ZMS-48 intergrowth zeolite and preparation and application thereof

A symbiotic molecular sieve, EU-1 technology, applied in molecular sieve catalysts, hydrocarbon cracking hydrocarbon production, bulk chemical production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0123] 16.25g NaOH was fully dissolved in 150.00g deionized water, 4.00g seed crystal (HEU-1 with a silicon-aluminum ratio of 500) was added to it, and reflux treatment was carried out under stirring for 2 hours to obtain seed crystal solution A; 8.75g NaOH was dissolved in 186.00g deionized In water, add 77.20g organic template agent 1,6-dibromide hexanebisammonium (HMBr 2 ) and 2.00g NaAlO 2 , Stir in a water bath at 40°C until completely dissolved to obtain solution B; add solution B dropwise to solution A under stirring, stir at 40°C-60°C for 2-4h to obtain mixed solution C; mix 400.00g of silica sol under vigorous stirring Slowly add it dropwise into the mixed solution C to obtain a silica-alumina gel, and the molar ratio of the gel is: SiO 2 / Al 2 o 3 =300,H 2 O / SiO 2 =12, HM / SiO 2 =0.08,Na 2 O / SiO 2 =0.12, where the amount of seed crystals is the amount of silicon source added to SiO 2 2.5wt.%, aged in a water bath at 60°C for 10 hours, then loaded into a 1L re...

Embodiment 2

[0125] 1.53g NaOH was fully dissolved in 30.00g deionized water, 0.80g seed crystal (HEU-1 with a silicon-aluminum ratio of 500) was added to it, and the seed crystal solution A was obtained by refluxing under stirring for 2 hours; 0.94g NaOH was dissolved in 18.00g deionized In water, add 9.65g organic template agent 1,6-dibromide hexanebisammonium (HMBr 2 ) and 0.24g NaAlO 2 , Stir in a water bath at 40°C until completely dissolved to obtain solution B; add solution B dropwise to solution A under stirring, stir at 40°C-60°C for 2-4h to obtain mixed solution C; mix 80.00g of silica sol under vigorous stirring Slowly add it dropwise into the mixed solution C to obtain a silica-alumina gel, and the molar ratio of the gel is: SiO 2 / Al 2 o 3 =500,H 2 O / SiO 2 =10, HM / SiO 2 =0.05, Na 2 O / SiO 2=0.06, where the amount of seed crystals is the amount of silicon source added to SiO 2 2.5wt.%, aged in a water bath at 60°C for 10h, then loaded into a 200mL reactor with a polytet...

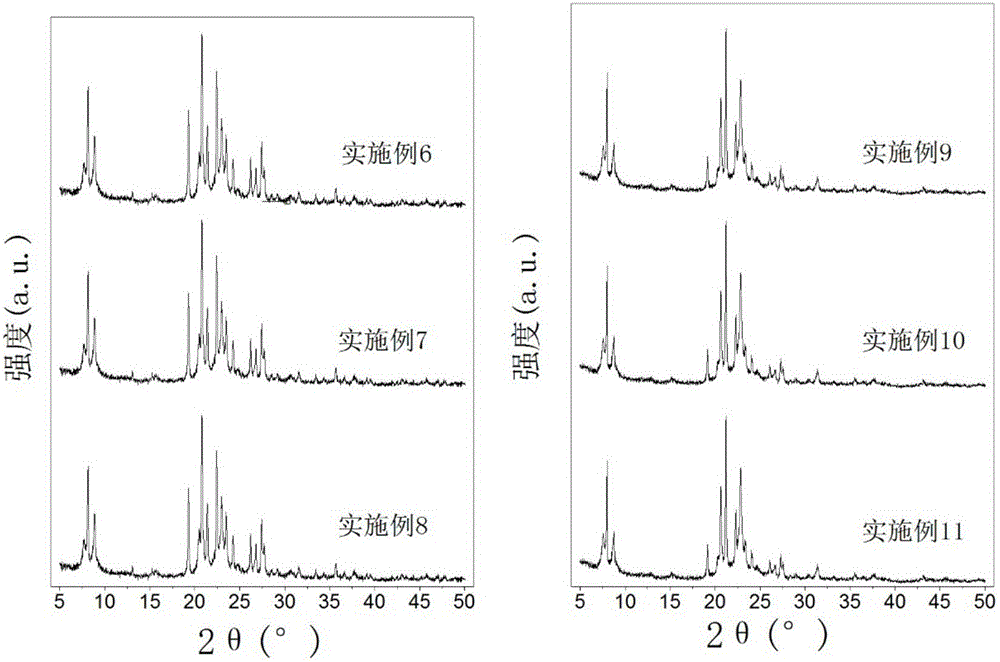

Embodiment 3-5

[0127] 4.75g NaOH was fully dissolved in 170.00g deionized water, 0.45g, 1.35g, 2.55g seed crystals (HEU-1 with a silicon-aluminum ratio of 300) were added to it, and the seed crystal solution A was obtained by refluxing under stirring for 2 hours; 3.17g NaOH Dissolve in 100.00g deionized water, add 27.15g organic template agent 1,6-dibromide hexanebisammonium (HMBr 2 ) and 0.23g NaAlO 2 , stirred in a water bath at 40°C until completely dissolved to obtain solution B; added solution B dropwise to solution A under stirring, and stirred at 40°C-60°C for 2-4h to obtain mixed solution C; Slowly add to the mixed solution C under stirring to obtain a silica-alumina gel, and the molar ratio of the gel is: SiO 2 / Al 2 o 3 =500,H 2 O / SiO 2 =30, HM / SiO 2 =0.15,Na 2 O / SiO 2 =0.20, where the amount of seed crystals is the amount of silicon source added to SiO 2 1.5wt%, 4.5wt.%, 8.5wt.%, aged in a water bath at 60°C for 10h, then loaded into a 500mL reactor with a polytetrafluoro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com