Bubble shirt looped cloth with composite fabric layer

A technology of composite fabrics and fabric layers, applied in the field of fabrics and textile fabrics, can solve the problems of no three-dimensional feeling, not fluffy, not soft, etc., and achieve the effect of enhancing three-dimensional feeling, thick hand feeling and full product.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

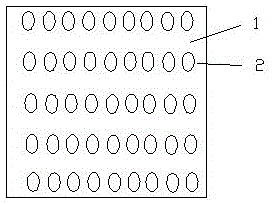

[0010] see figure 1 , The present invention relates to a bubble shirt loop fabric with a composite fabric layer, comprising a shirt fabric body 1, and a plurality of rows of bubbles 2 are arranged on the outer surface of the shirt fabric body 1. The bubbles 2 are heat-pressed to have an oval shape and protrude from the fabric body 1 .

[0011] The fabric body 1 is made of fabric, and the fabric is formed by interweaving warp yarns and weft yarns, wherein the warp yarns include loop yarns and ground yarns, and the loop yarns span a certain number of weft yarns to form a fixed weave. Among them, three weft yarns are separated between the starting point and the end point of the loop formed by the loop yarn; the fixed ground structure formed by the bottom yarn is separated by three weft yarns between adjacent interweaving points. A composite fabric layer is arranged under the fabric, and the composite fabric layer includes a first soft and wear-resistant veneer layer, a silver fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com