Feed, premix and preparation method thereof for improving vanadium-induced decline in egg processing characteristics

A technology of processing characteristics and premix, which is applied in food processing, animal feed, animal feed, etc., can solve the problem of the decline of egg processing characteristics, and achieve the effect of improving the quality of protein processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The present invention also provides a method for preparing feed for improving the degradation of egg processing characteristics caused by vanadium, which includes the following steps:

[0025] Step 1. Prepare premix, weigh, tea polyphenols 22-28 parts, vitamin C 8-12 parts, vitamin E1-3 parts, β-carotene 3-8 parts, lycopene 3 parts- 8 parts, resveratrol 3-8 parts, sodium selenite 0.2-0.8 parts, hulling 40-50 parts;

[0026] Step 2. Weigh, corn 62 parts-68 parts, soybean oil 0.1 parts-0.45 parts, soybean meal 21 parts-26 parts, calcium carbonate 7 parts-9 parts, calcium hydrogen phosphate 1 part-2 parts, salt 0.2 part-0.35 parts Parts, choline chloride 0.16 parts to 0.20 parts, composite multidimensional 0.01 parts to 0.05 parts, mineral addition premix 0.10 parts to 0.2 parts, DL-methionine 0.1 part to 0.2 parts, premixed material 0.18 parts to 0.3 parts;

[0027] Step 3. The corn and soybean meal are crushed to a particle size of 1500 μm, and then the above-mentioned compone...

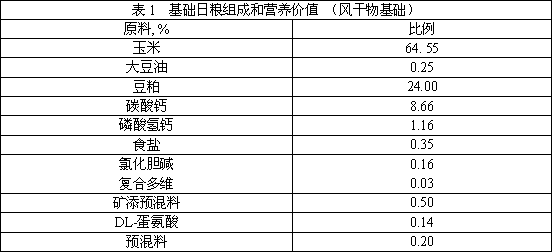

Embodiment 1

[0029] Weigh the following components according to mass parts: 25 parts of tea polyphenols, 10 parts of vitamin C, 2 parts of vitamin E, 5 parts of β-carotene, 5 parts of lycopene, 5 parts of resveratrol, and 0.4 parts of sodium selenite 47.6 parts of husk; then mix evenly to make a premix; weigh the following components according to parts by mass: 64.55 parts of corn, 0.25 parts of soybean oil, 24.00 parts of soybean meal, 8.66 parts of calcium carbonate, 1.16 parts of calcium hydrogen phosphate, 0.35 parts of table salt, 0.16 parts of choline chloride, 0.03 parts of compound multi-dimensional, 0.50 parts of mineral premix, 0.14 parts of DL-methionine, 0.20 parts of premix, crush corn and soybean meal to a particle size of 1500μm, and then crush the above components Through the step-by-step mixing method, the mixture is evenly mixed to make compound feed.

Embodiment 2

[0031] Weigh the following components according to mass parts: 22 parts of tea polyphenols, 12 parts of vitamin C, 1 part of vitamin E, 8 parts of β-carotene, 3 parts of lycopene, 8 parts of resveratrol, and 0.2 parts of sodium selenite Parts, hulled 50 parts; then mix evenly to make a premix; weigh the following components according to mass parts: 62 parts corn, 0.45 parts soybean oil, 21 parts soybean meal, 9 parts calcium carbonate, 1 part calcium hydrogen phosphate, 0.35 parts of salt, 0.16 parts of choline chloride, 0.05 parts of compound multi-dimensional, 0.10 parts of mineral premix, 0.2 parts of DL-methionine, 0.18 parts of premix; crush the corn and soybean meal to a particle size of 1500μm, and then the above components Through the step-by-step mixing method, the mixture is evenly mixed to make compound feed.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap