Shaker

A vibrating screen and screen box technology, which is applied in the fields of filtration, solid separation, chemical instruments and methods, etc., can solve the problems of uneven distribution of minerals, low screening efficiency, and easy wear of the screen, so as to prolong the service life and reduce friction , the effect of slowing down wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

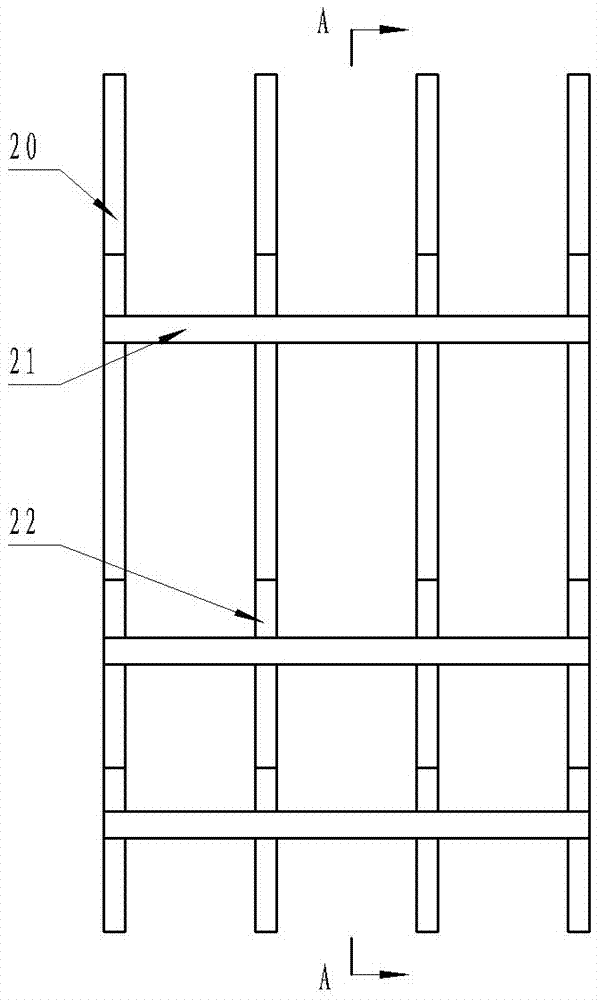

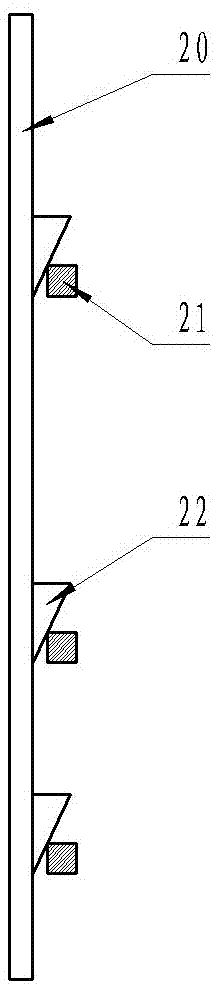

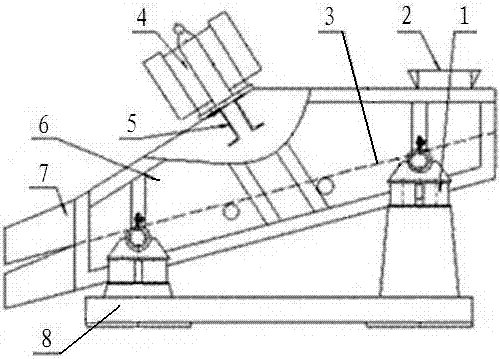

[0018] Such as image 3 , Figure 4 The shown vibrating screen includes a screen box 6 with a feed inlet 2 and a discharge outlet 7. The screen box 6 is obliquely installed on the bracket 8 through the damping spring 1, and the middle top position of the screen box 6 is equipped with Motor pedestal 5, two vibrating motors 4 are fixed on the motor pedestal 5 through mounting bolts, two layers of screen 3 are installed in the screen box 6 through the screen frame, and two long layering strips parallel to the material conveying direction are installed on the screen 3 10. Above the two long layering bars 10, there are three spaced horizontal pressing bars 11 fixed on both sides of the screen box 6, and four short layering bars 9 are installed between the two long layering bars 10, and the two short layering bars 9 are arranged along the material The conveying direction is arranged at intervals, and the distance between the two short layering bars 9 arranged at intervals along the...

Embodiment 2

[0021] The difference between this embodiment and Embodiment 1 is that the distance between the two short bead 9 arranged at intervals along the material conveying direction is 350 millimeters; The distance L is 150 mm. All the other features are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com