Wire fixing clamp

A wire fixing and wire clip technology, used in cable installation, overhead installation, electrical components, etc., can solve the problems of easy loosening, potential safety hazards, time-consuming and labor-intensive fixing of wires and insulators, etc. The effect of increasing the working time and enhancing the reliability of the power supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

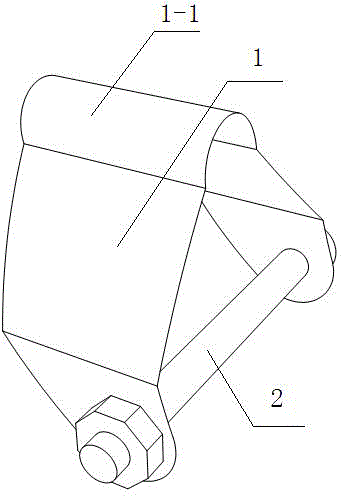

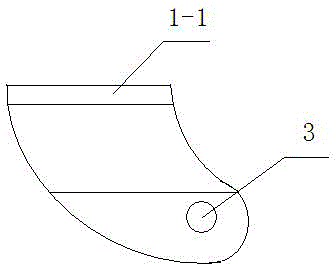

[0014] Such as Figure 1-3 As shown, the present invention includes a clamp body 1 and a fixing member 2. The clamp body 1 includes a clamping groove 1-1 for clamping wires, and fixed wings on both sides of the clamping groove 1-1. Set connection hole 3.

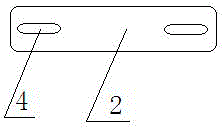

[0015] The fixing member can also be a fixing card, and a screw hole 4 is respectively provided at both ends of the fixing card, and the screw hole 4 is used for correspondingly connecting the connecting holes 3 on the two fixing wings.

[0016] The fixing member may be a screw rod and a nut, and the screw rod penetrates through the two connection holes 3 and is then rotatably connected and fixed with the nut. When the fixing part of this kind of structure is adopted, it is more convenient to adjust, and the nut can be loosened to be installed, and the nut can be tightened to be fixed.

[0017] During use, a product of the present invention is respectively arranged at both ends of the wire to be fixed, and the fixing parts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com