Mould used for heat insulation parts of door body of refrigerator and freezer

A part and mold technology, applied in the field of molds for refrigerator and freezer door body insulation parts, can solve the problems of door weight, poor product quality and high production cost, reduce production cost, save pre-installation process, and achieve good sealing effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

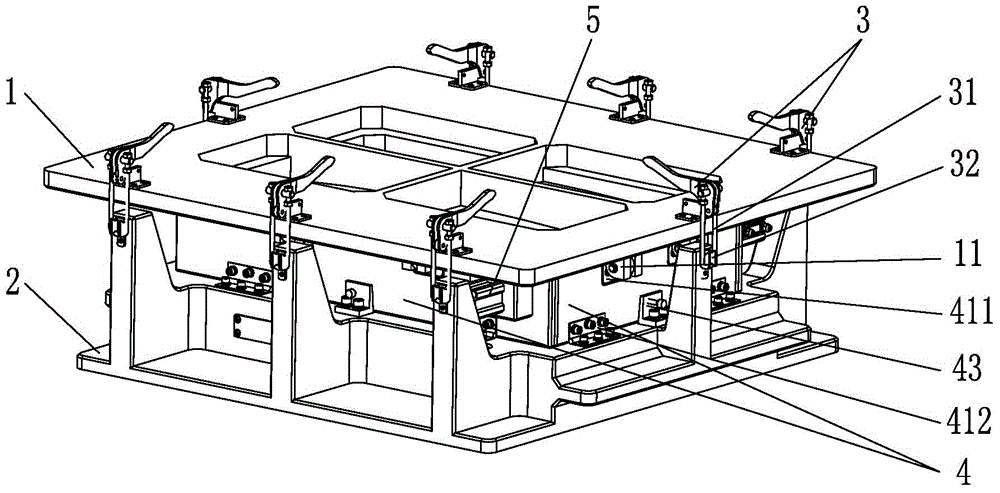

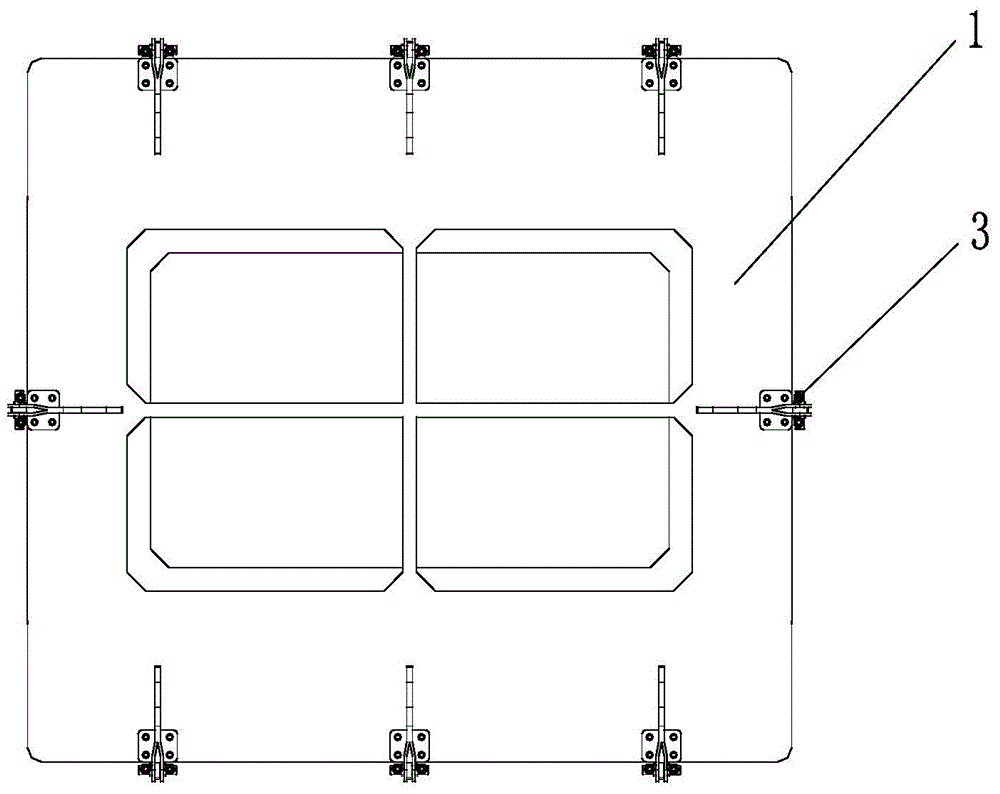

[0046] Such as figure 1 with Figure 4 As shown, this embodiment provides a mold for refrigerator and freezer door insulation components, which includes an upper template 1, a lower template 2, a locking mechanism 3, a sidewall mechanism 4, and a pneumatic core pulling mechanism 5. The upper template The mold cavity shape of 1 matches the shell of the thermal insulation component, and the cavity shape of the lower template 2 matches the inner lining of the thermal insulation component; when the mold is closed, the locking mechanism 3 is used to lock the upper template 1 and the lower template 2 Tight; The sidewall mechanism 4 is set between the upper template 1 and the lower template 2, and assists in locking the upper template 1 and the lower template 2 when the mold is closed, and is turned over by the pneumatic core pulling mechanism 5 when the mold is demolded, Realize the demoulding of the undercut structure.

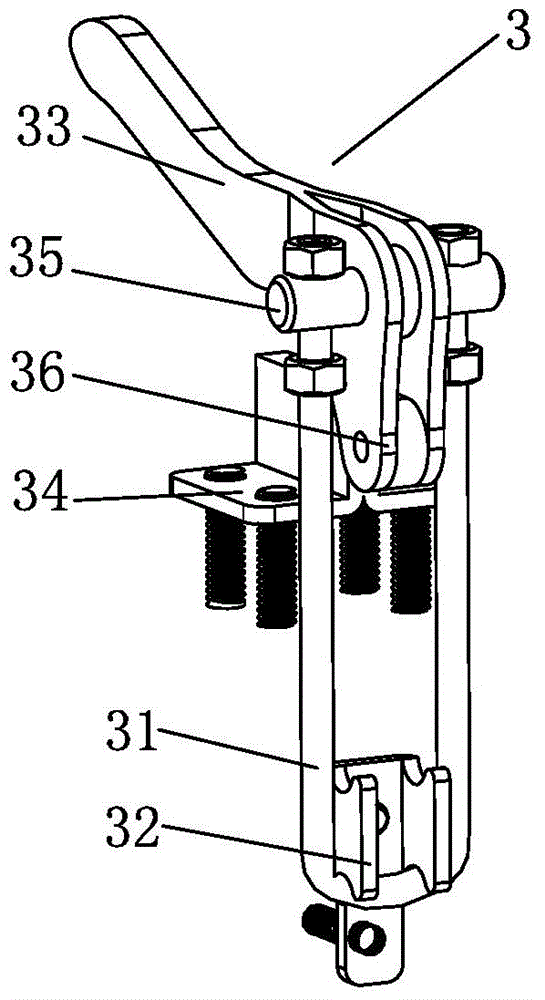

[0047] The installation position and structure of the locking me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com