Flat pneumatic tyre

A technology for pneumatic tires and tires, which is applied to the reinforcement layer, tire parts, tire edges and other directions of pneumatic tires, can solve the problems of complex manufacturing process, intensive material consumption, personnel and equipment, and achieves small circumferential deformation and guaranteed load bearing. Demand, the effect of low heat generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

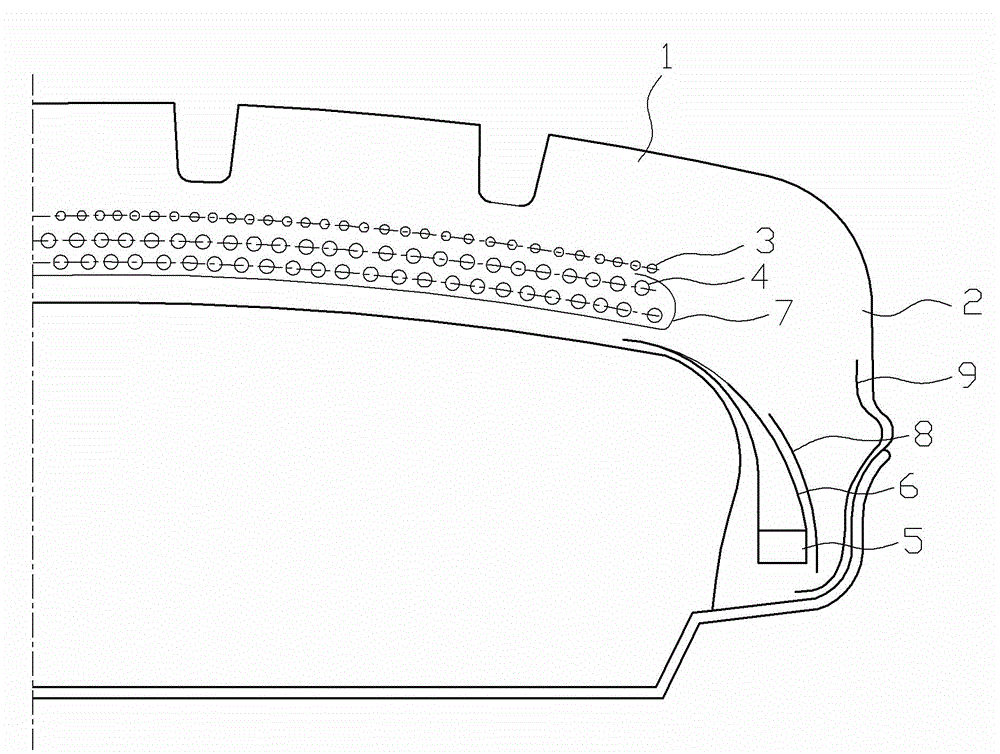

[0022] Such as figure 1 As shown, in a flat pneumatic tire, the tire body includes a crown portion 1 and a bead portion 2, and the tire body is provided with a cap layer 3, a belt layer 4, a bead wire 5 and a wire ring 6, and the tire body It consists of two parts, the crown part 1 and the bead part 2. The cap layer 3 and the belt layer 4 are arranged on the crown part 1, and a stress balance layer 7 is arranged under the belt layer 4. The stress balance layer 7 The two ends are wrapped around the end of the belt layer 4 and sandwiched between the cap layer 3 and the belt layer 4, and the two ends of the traveler cloth 6 are overlapped and overlapped under the edge of the stress balance layer 7 .

[0023] The bead portion 2 is provided with a bead reinforcing layer 8 , and the bead reinforcing layer 8 is attached to the outer side of the flipper 6 .

[0024] The bead portion 2 is provided with a chafer 9 along its outer edge.

[0025] The stress balance layer is made of fib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com