Rail car train

A technology for rail vehicles and trains, applied in the field of rail vehicles and trains, can solve problems such as the limited load-bearing capacity of cranes, and achieve the effect of improving the load-bearing capacity and increasing the swing range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

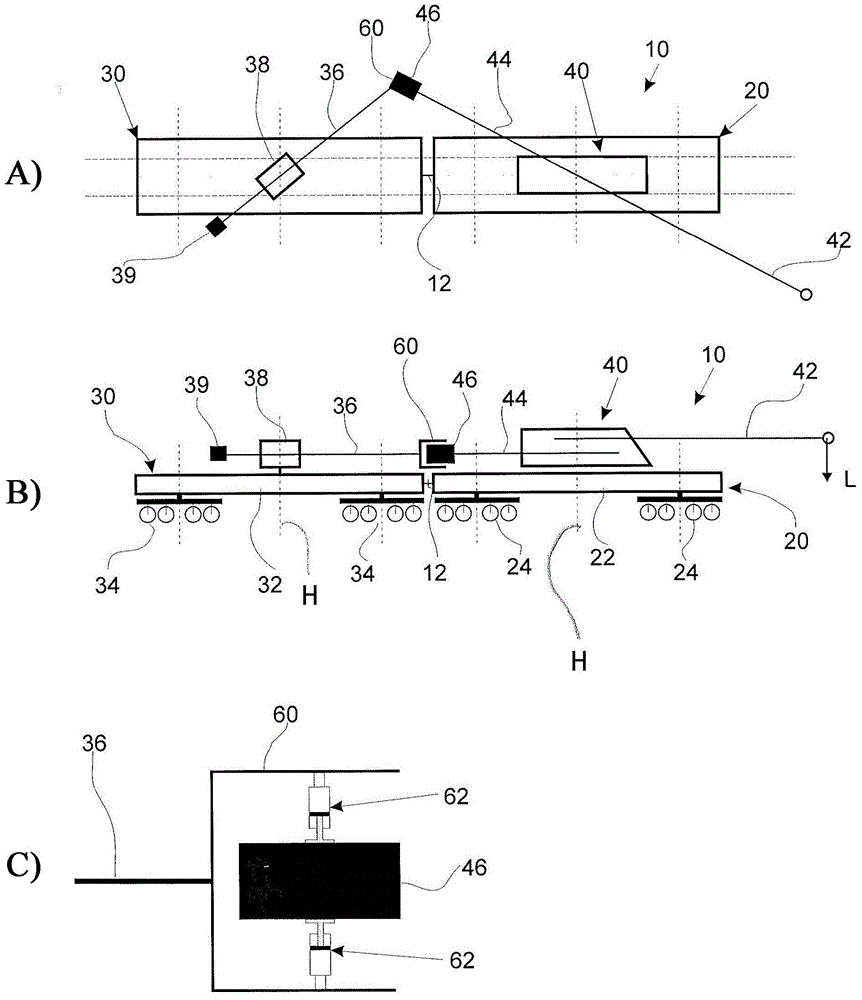

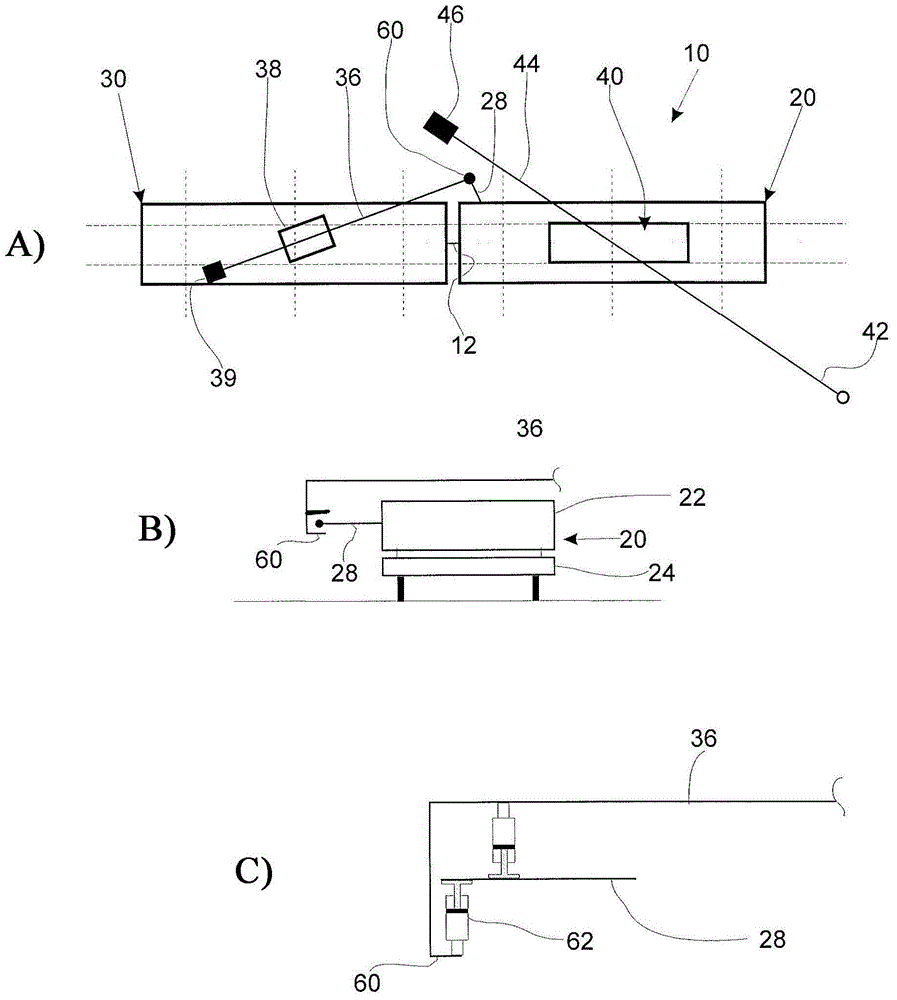

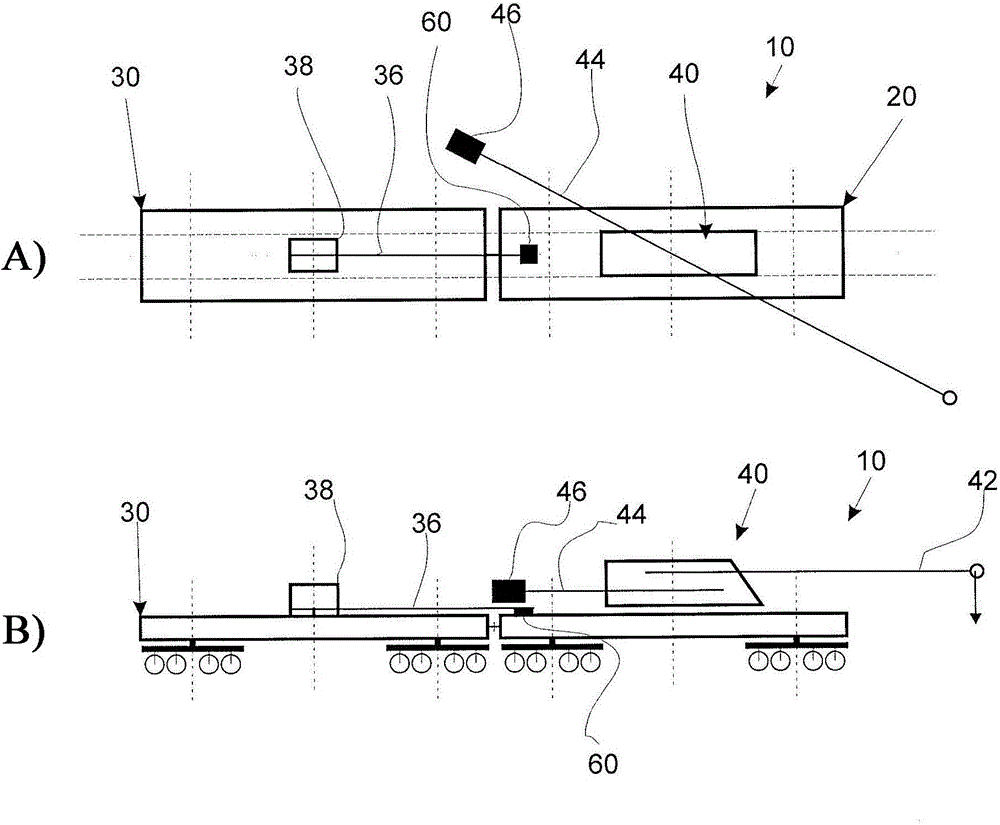

[0035] exist figure 1 In A and B, a rail vehicle train is shown schematically in plan view and side view, and is designated as a whole by the reference numeral 10 . The schematic diagram mainly shows only the components necessary to explain the invention. All other components are not shown for clarity.

[0036] The rail vehicle train 10 comprises at least one first rail vehicle 20 and a second rail vehicle 30 , which can be directly connected (coupled) to one another via corresponding devices 12 if necessary. Both rail vehicles 20 , 30 each comprise an undercarriage 22 or 32 , on which at least two running gears or bogies 24 or 34 each have at least one axle, preferably several axles, respectively.

[0037]The first rail vehicle 20 has a crane body 40 having a crane jib 42 , a counterjib 44 and a counterweight 46 . Both arms 42 , 44 are arranged rotatably about a vertical axis H and can also be moved preferably telescopically in their longitudinal direction. The swivel or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com