Arc-shaped plate fixed-distance conveying method for ampoules

A curved plate and ampoule technology, which is applied in the field of conveying, can solve the problems of ampoule damage and ampoule fixed-distance transmission mechanism damage, and achieves the effect of preventing breakage, simple structure and protecting the ampoule.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The fixed-distance conveying method of an ampoule with a curved plate comprises the following steps:

[0027] (1) Adjust the distance between the first arc-shaped protection plate and the second arc-shaped protection plate on the bottom plate of the trough according to the size of the conveying ampoule, and use the bolts and nuts below the bottom plate of the chute to protect the first arc-shaped protection plate. The positions of the plate and the second arc protection plate are fixed;

[0028] (2) Put the ampoule on the bottom plate of the trough, and the ampoule is transported to the conveyor belt through the guide channel formed by the first arc-shaped protective plate and the second arc-shaped protective plate, and the transport is limited by the ampoule block on the conveyor belt. The distance between the bottles, and finally the ampoule with a limited distance can be transmitted.

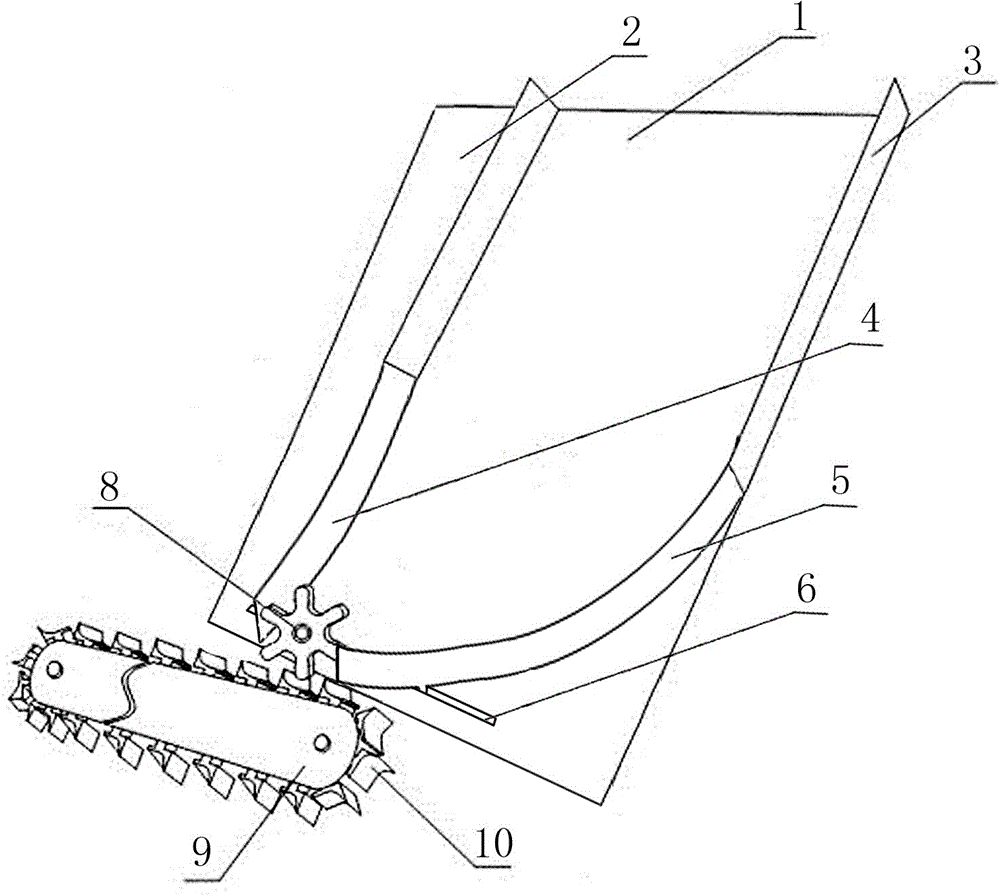

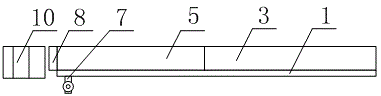

[0029] In the present invention, the structure of the arc-shaped plate fixed-dist...

Embodiment 2

[0035] The difference between this embodiment and Embodiment 1 is that between the ampoule release mechanism and the ampoule fixed-distance transmission mechanism, an ampoule guide wheel 8 is added at the position of the ampoule release mechanism, and the specific settings are as follows:

[0036] The guide passage outlet is also provided with an ampoule guide wheel 8, which is made up of a gear-shaped runner located at the guide passage outlet, and a motor that drives the runner to rotate.

Embodiment 3

[0038] The difference between this embodiment and Embodiment 2 is that the structure of the ampoule fixed-distance transmission mechanism is optimized, and the specific setting method is as follows:

[0039] The ampoule block 10 is strip-shaped, and its length direction is parallel to the width direction of the conveyor belt 9. The bottom end of the ampoule block 10 is fixedly connected to the conveyor belt 9, and an arc-shaped surface is arranged on the upper part of the ampoule block 10. , the arc-shaped surface is tangent to one side of the ampoule block 10 , and the arc-shaped surface intersects the other side of the ampoule block 10 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com