Self-tightening type bone drilling machine head

A self-tightening, bone drill technology, applied in the field of medical devices, can solve problems such as damage or slippage, complicated installation process, and no self-tightening function, and achieve simple and convenient use, compact overall structure, and good clamping reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

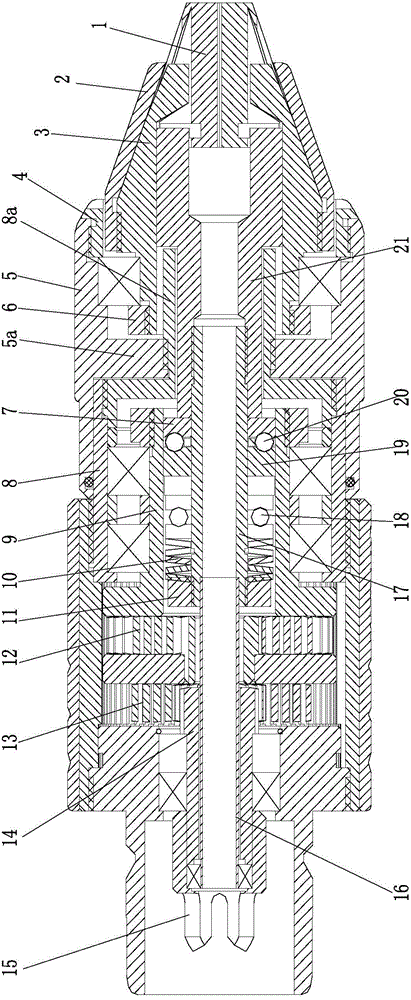

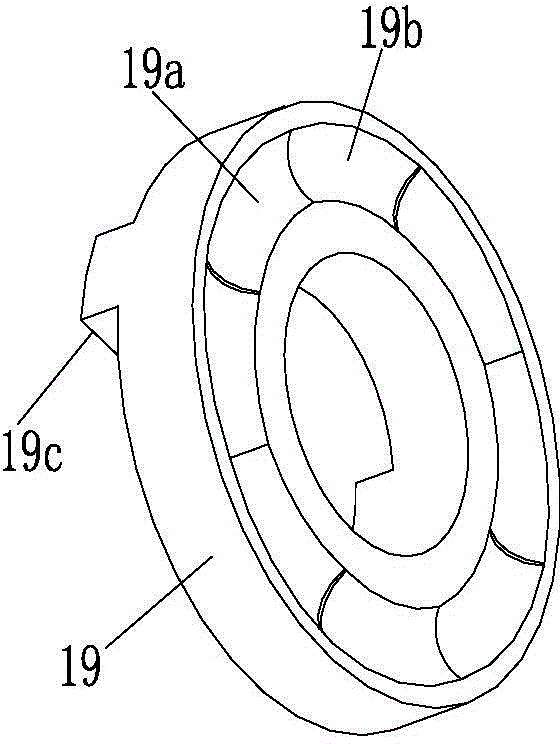

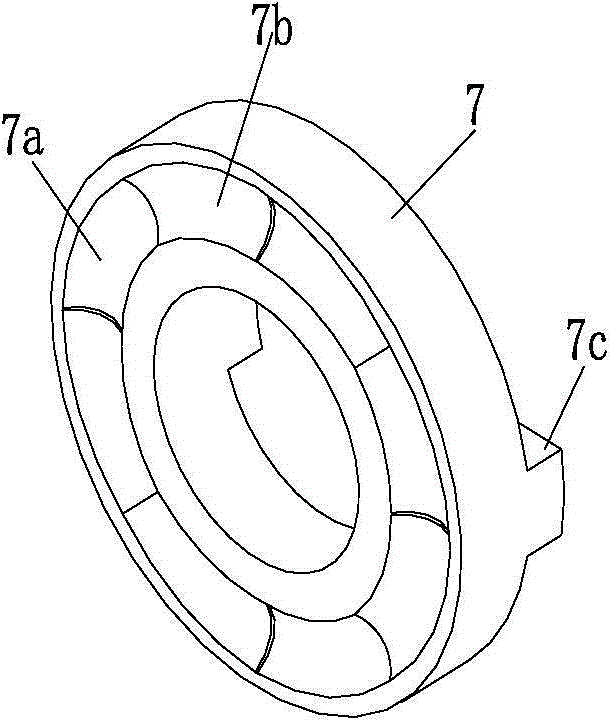

[0026] figure 1 It is a structural schematic diagram of the present invention, figure 2 It is a schematic diagram of the structure of the active end face cam sleeve, image 3 It is a schematic diagram of the structure of the cam sleeve on the driven end face, Figure 4 is a schematic diagram of the jaw structure, Figure 5 It is a schematic diagram of the structure of the transmission sleeve of the jaw group, Figure 6 is the schematic diagram of the input drive sleeve structure, Figure 7 It is a schematic diagram of the structure of the inner guide sleeve, Figure 8 It is a schematic diagram of the axial side of the input transmission sleeve, as shown in the figure: the self-tightening bone drill head of this embodiment includes a chuck assembly, and the chuck assembly includes a jaw set and a jaw guide sleeve, and the jaw set and the jaw guide sleeve make the jaw set clamp or release the drill bit through axial relative movement, and also include an end face cam pair,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com