Chain type sewing machine special for knitted hat

A sewing machine and chain technology, applied in sewing machine components, control devices for sewing machines, sewing equipment, etc., can solve the problems of loud noise, oil splashing, easy damage, etc., and achieve the effect of beautiful elasticity, reduced wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

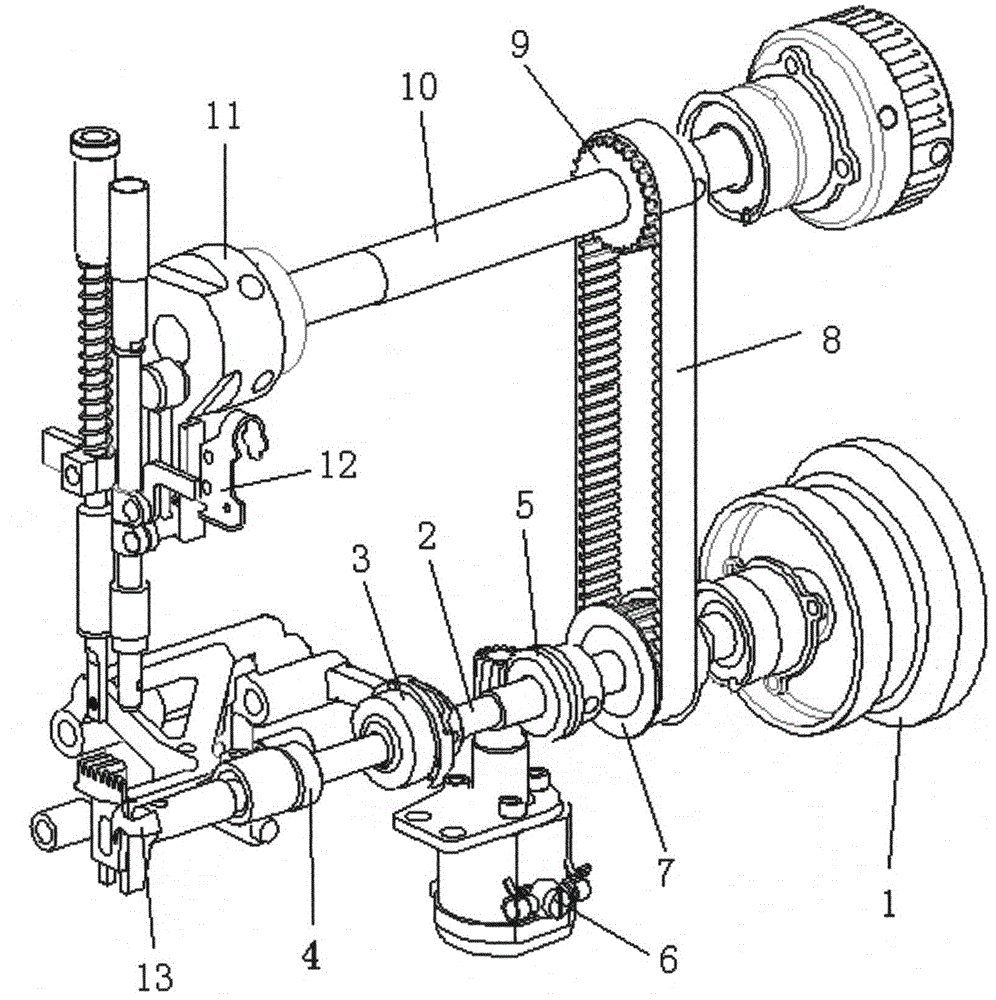

[0013] Such as figure 1 As shown, the special chain sewing machine for braided caps of the present invention includes a pulley (1), a main shaft, an eccentric cam assembly, a turbine (5), an oil pump (6), a main shaft synchronous pulley, a synchronous belt (8), and a thread take-up lever crank (11), thread take-up lever assembly (12), hook needle (13); the main shaft synchronous pulley is fixed on the main shaft by a key; the main shaft includes an upper main shaft (10) and a lower main shaft (2); the main shaft is synchronous The pulleys include an upper main shaft synchronous pulley (9) and a lower main shaft synchronous pulley (7); the eccentric cam assembly includes a feeding eccentric cam assembly (3) and a tooth lifting eccentric cam assembly (4); the pulley (1) It is fixed on the right side of the lower main shaft (2) by bolts; the feeding eccentric cam assembly (3) is fixed on the middle position of the lower main shaft (2) by bolts; the tooth lifting eccentric cam ass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com