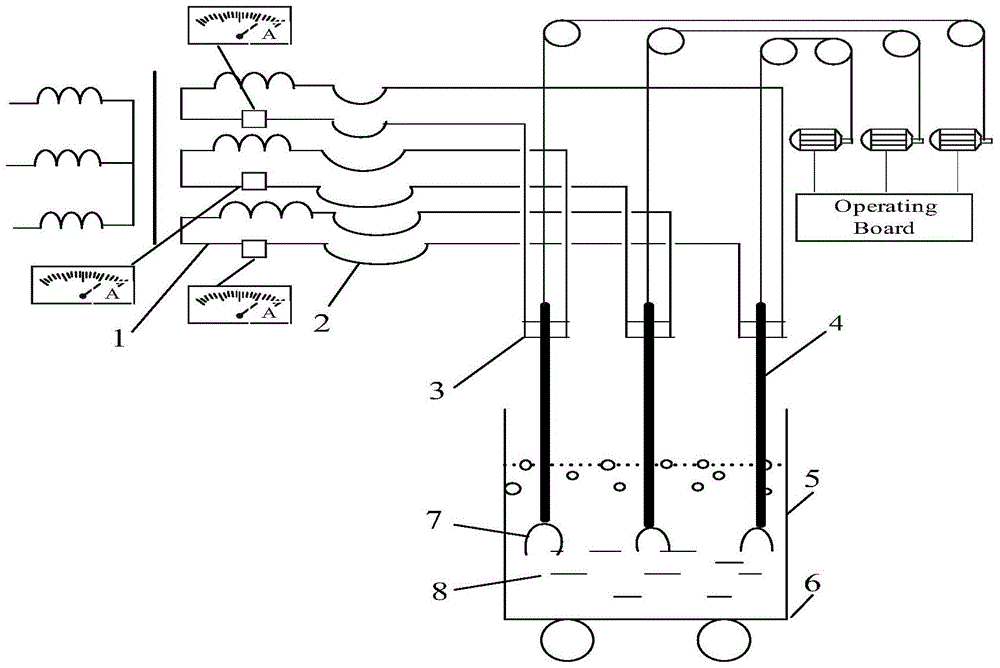

A method of industrial process fault diagnosis based on kpca

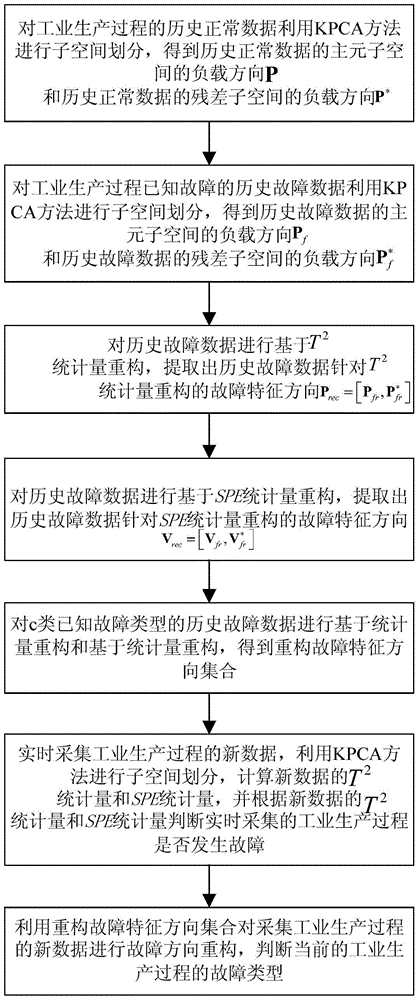

A fault diagnosis and industrial process technology, applied in the direction of instruments, electrical testing/monitoring, control/regulation systems, etc., can solve the problem of inability to effectively distinguish fault information from normal information, excessive reconstruction, and inability to reflect the nonlinear characteristics of data, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

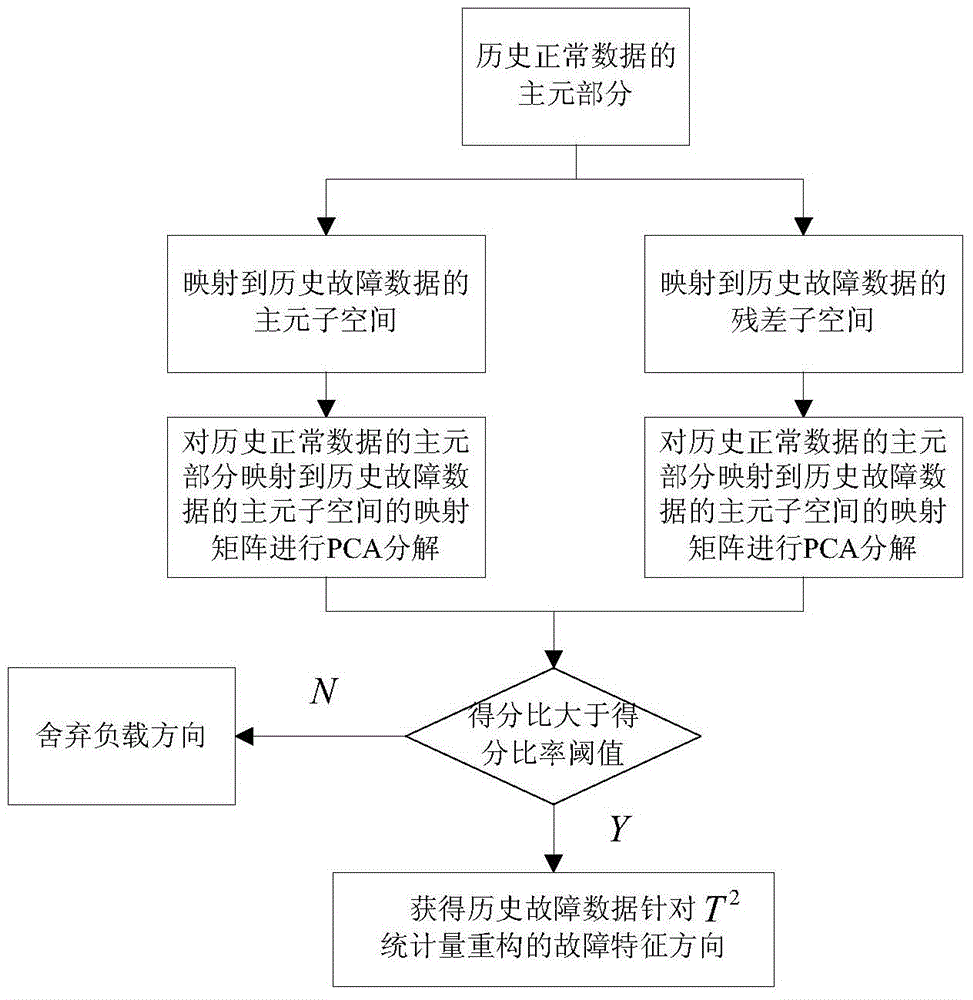

Method used

Image

Examples

Embodiment 1

[0215] Real-time collection of 400 new data 1 of the smelting process of the fused magnesium furnace, the T of the new data 1 2 Statistical detection diagram and SPE statistical detection diagram such as Figure 6 As shown, among them, Figure 6 (a) T for the new data 2 Statistics check chart, Figure 6 (b) is the SPE statistic detection chart of the new data. It can be seen from the figure that the T of the new data 1 2 Both statistics and SPE statistics began to exceed the limit at about the 101st sampling point, and formed a stable alarm, indicating that a fault occurred.

[0216] For new data 1, use the historical fault data of type l for T 2 According to the fault characteristic direction reconstructed by statistics, the fault direction is reconstructed for the new data, and the fault direction is reconstructed for the new data according to the fault characteristic direction reconstructed by the SPE statistics by using the historical fault data of type l.

[0217] Fo...

Embodiment 2

[0221] Real-time collection of 400 new data 2 of the smelting process of the fused magnesium furnace, the T of the new data 2 2 Statistical detection diagram and SPE statistical detection diagram such as Figure 9 As shown, among them, Figure 9 (a) T for the new data 2 Statistics check chart, Figure 9 (b) is the SPE statistic detection diagram of the new data. It can be seen from the figure that the T of the new data 2 2 Both statistics and SPE statistics began to exceed the limit around the 150th sample, and formed a stable alarm, indicating that a fault occurred.

[0222] For the new data 2, use the l-type historical fault data for T 2 According to the fault characteristic direction reconstructed by statistics, the fault direction is reconstructed for the new data, and the fault direction is reconstructed for the new data according to the fault characteristic direction reconstructed by the SPE statistics by using the historical fault data of type l.

[0223] For class...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com