A photoelectric logic gate based on tin dioxide nanoparticles and its preparation method

A technology of tin dioxide and nanoparticles, applied in logic circuits using optoelectronic devices, logic circuits using specific components, logic circuits, etc., can solve problems such as incomplete functions of optoelectronic logic gates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

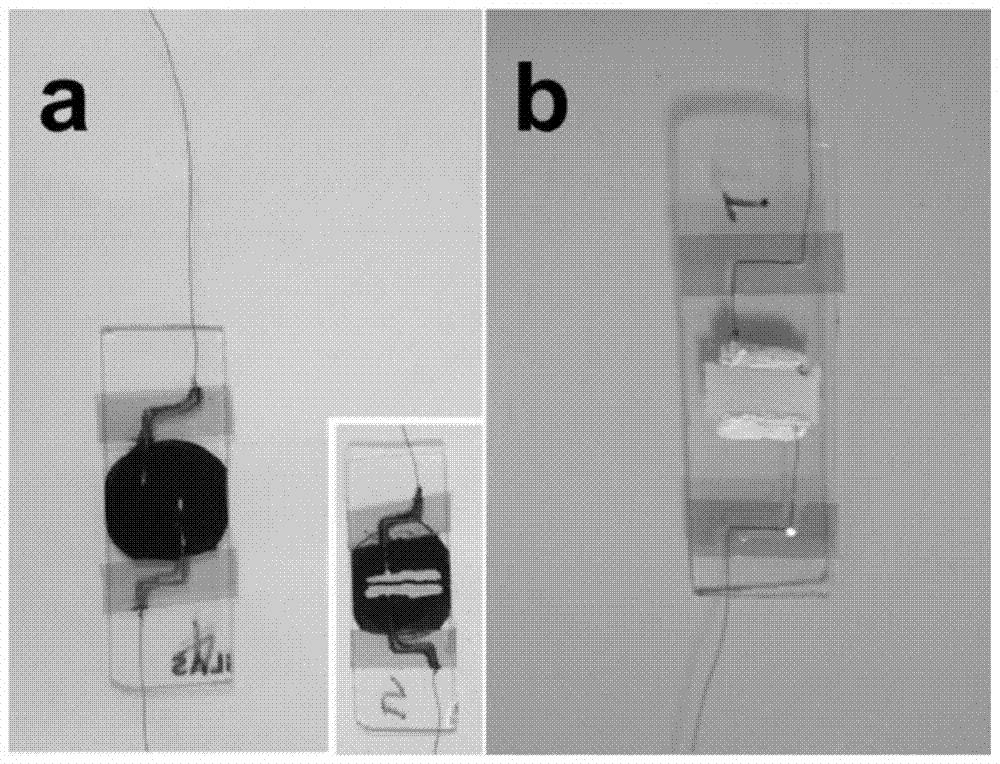

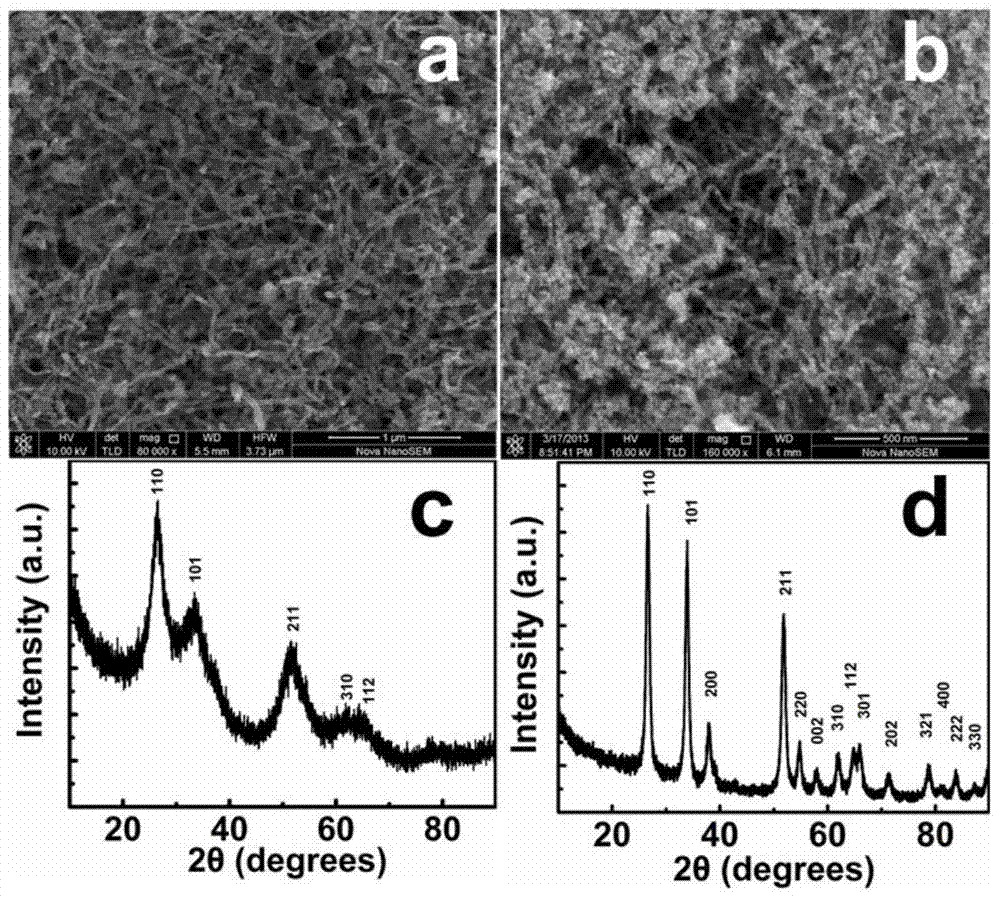

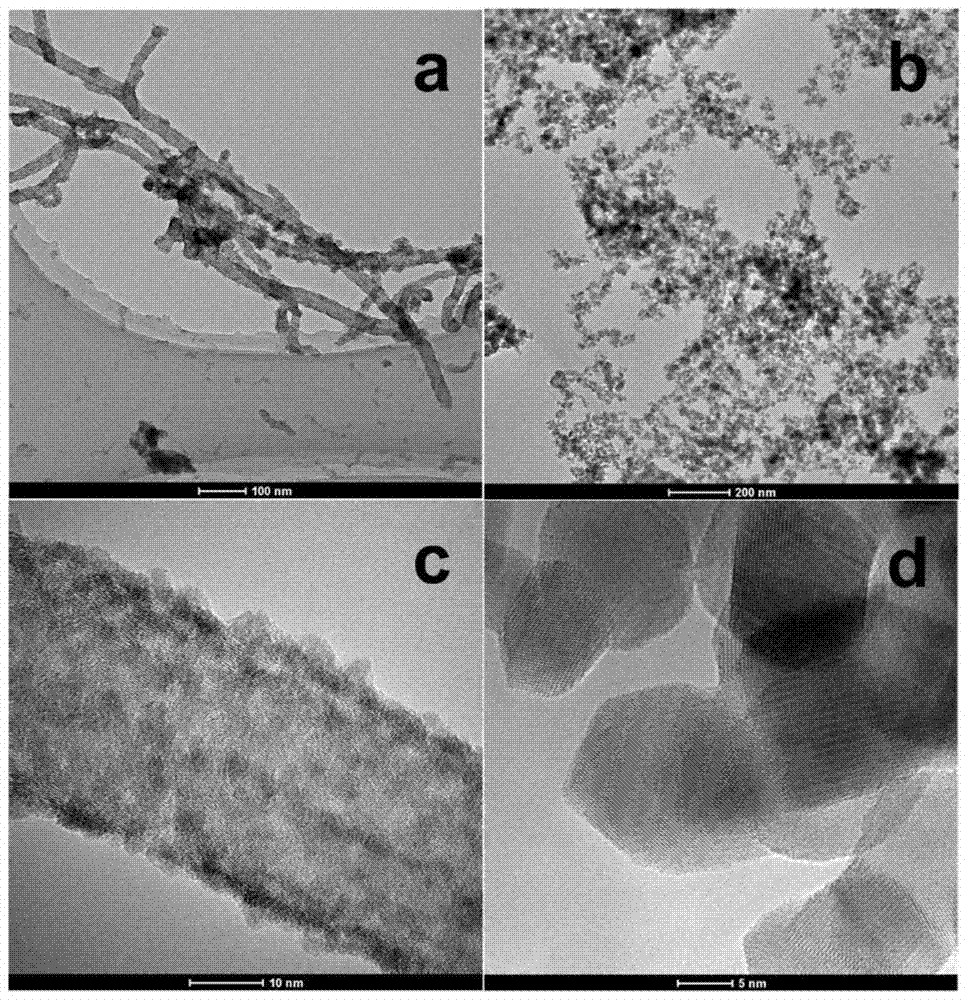

[0080] Both the negative photoconductive device and the positive photoconductive device in the present invention adopt an insulating substrate (such as a glass slide; because the input optical signal can directly irradiate on the material of the positive / negative photoconductive effect, such as tin dioxide nanoparticles, so the insulation The substrate is not required to be a light-transmitting insulating substrate) as the substrate, and the cost is low. Negative photoconductive devices use tin dioxide-coated carbon nanotube composites as working materials, which are easy to synthesize and make devices, and do not need to be packaged in vacuum or other harsh environments; positive photoconductive devices are simply annealed on the basis of negative photoconductive devices Only processing is required, the process is simplified and the cost is reduced. The negative photoconductive device and the positive photoconductive device are connected by copper wires to form a photoelectri...

Embodiment 2

[0100] Its preparation method of the optoelectronic logic gate based on tin dioxide nanoparticles in embodiment 2 is basically the same as embodiment 1, the difference is:

[0101] In step 1, the concentrated nitric acid volume that mass fraction is 65% is 30mL, and deionized water volume is 20mL, is made into the 40% nitric acid solution of 50mL;

[0102] In step 2, the quality of adding carbon nanotubes is 67 mg, and the stirring and reflux time of the solution is 8 hours;

[0103] In step 3, the obtained powder was dried at 70°C for 24 hours;

[0104] In step 4, the mass of stannous chloride dihydrate added is 0.45 g (i.e. 0.05 mol / L stannous chloride solution), the volume of 37% hydrochloric acid is 0.5 mL, and the mass of carbon nanotubes after drying is 8 mg;

[0105] In step 5, the temperature of the water bath is 50°C, and the duration is 4 hours;

[0106] In step 7, the silver paste pattern is 2mm×5mm, with a distance of about 0.1mm, and the annealing condition is 1...

Embodiment 3

[0111] Its preparation method of the optoelectronic logic gate based on tin dioxide nanoparticles in embodiment 3 is basically the same as embodiment 1, the difference is:

[0112] In step 1, mass fraction is that the concentrated nitric acid volume of 65% is 61mL, and ion water volume is 39mL, is made into the 40% nitric acid solution of 100mL;

[0113] In step 2, the quality of adding carbon nanotubes is 134 mg, and the stirring and reflux time of the solution is 12 hours;

[0114] In step 3, the obtained powder was dried at 90°C for 6 hours;

[0115] In step 4, the mass of stannous chloride dihydrate added is 1.36 grams (i.e. 0.15 mol / L stannous chloride solution), the volume of 37% hydrochloric acid is 1 mL, and the mass of carbon nanotubes after drying is 12 mg;

[0116] In step 5, the temperature of the water bath is 70°C, and the duration is 2 hours;

[0117] In step 7, the silver paste pattern is 2mm×8mm, with a distance of about 0.5mm, and the annealing condition is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com