Railway turnout point rail close-fit crawling monitor

A sharp rail and close-fitting technology, which is applied in the field of machinery, can solve the problems of labor-consuming and time-consuming, the inability to grasp the operation status of railway turnouts in time, hidden dangers of train operation safety, etc., and achieve the advantages of increased monitoring frequency, convenient installation and debugging, and short construction period Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

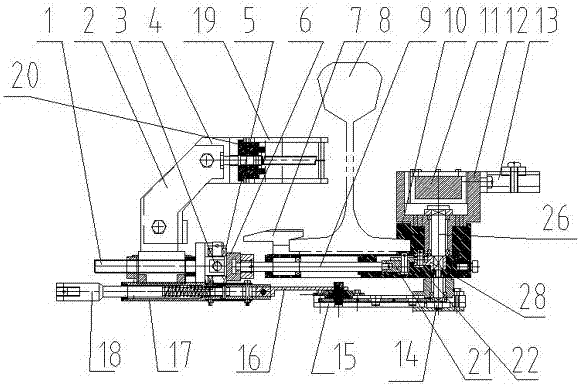

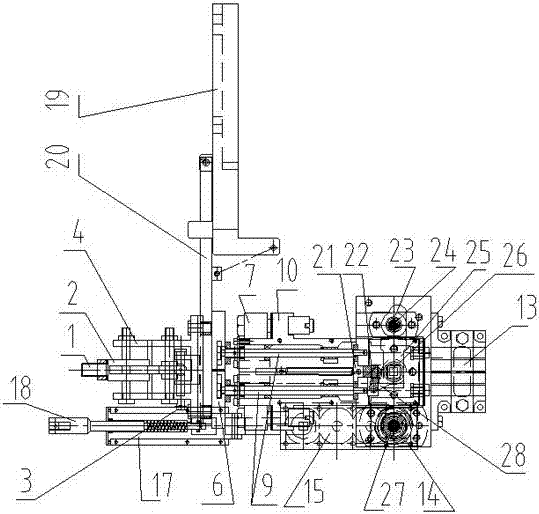

[0011] For a better understanding and implementation, the present invention will be further described below in conjunction with the accompanying drawings: the railway switch point rail close-fitting crawling monitor includes a point rail target assembly connected to the movable point rail through an insulating pad, and the point rail target position The assembly includes a switch rail attachment 1, the switch rail attachment 1 is provided with a switch rail kit 2 and a close-fitting wheel 5, the switch rail kit 2 is provided with a switch rail connector 4, and the switch rail connector 4 is connected with the anti-pinch arm 20, The anti-clamp arm 20 is connected with the adapter arm 19, and is stuck on the outer clamp seat 7 and the inner clamp seat 10 below the fixed rail 8, and the outer clamp seat 7, the inner clamp seat 10 and the fixed rail 8 are connected by bolts, and the inner clamp seat 10 There is a main body seat 12 on the top, and the main body seat 12 is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com