Automatic finishing process of glass bottle mouth mold

A technology for glass bottle cans and mouth molds, which is applied in the field of automatic finishing technology of glass bottle can mouth molds, can solve the problems of long processing time, poor processing accuracy and consistency, low work efficiency, etc., so as to improve production efficiency and improve precision. and consistency, reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

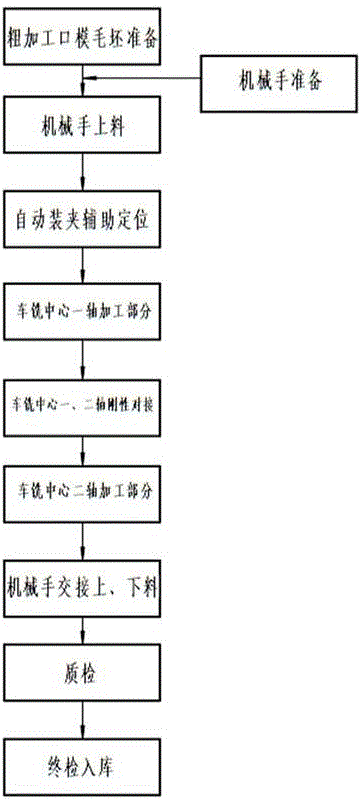

[0019] As shown in the figure, an automatic finishing process for glass bottle mouth molds, using automatic clamping and positioning auxiliary devices to automatically level and align the end faces of glass molds composed of two half-moulds, and equipped with a truss manipulator through a double-spindle turning and milling center One set, the manipulator is equipped with two sets of manipulator fingers with a conversion mechanism, and simultaneously completes multiple processing procedures of turning, milling, drilling, and lettering for the finishing of glass bottle mouth molds on one processing equipment. The specific process steps are as follows:

[0020] 1) Rough machining die blank preparation: place the die blanks that have been roughly machined in advance with ordinary equipment in the direction perpendicular to the seam line and the direction of travel of the feed channel, and place them neatly in the pallet-type feeding channel warehouse; the inner cavity is not For pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com