A ground sliding flexible assembly system

A ground sliding and flexible technology, applied in auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of single fixture switching method, high repeatability requirements, and large occupied area, so as to meet the requirements of random fixture switching, The switching method is flexible and the effect of reducing the floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

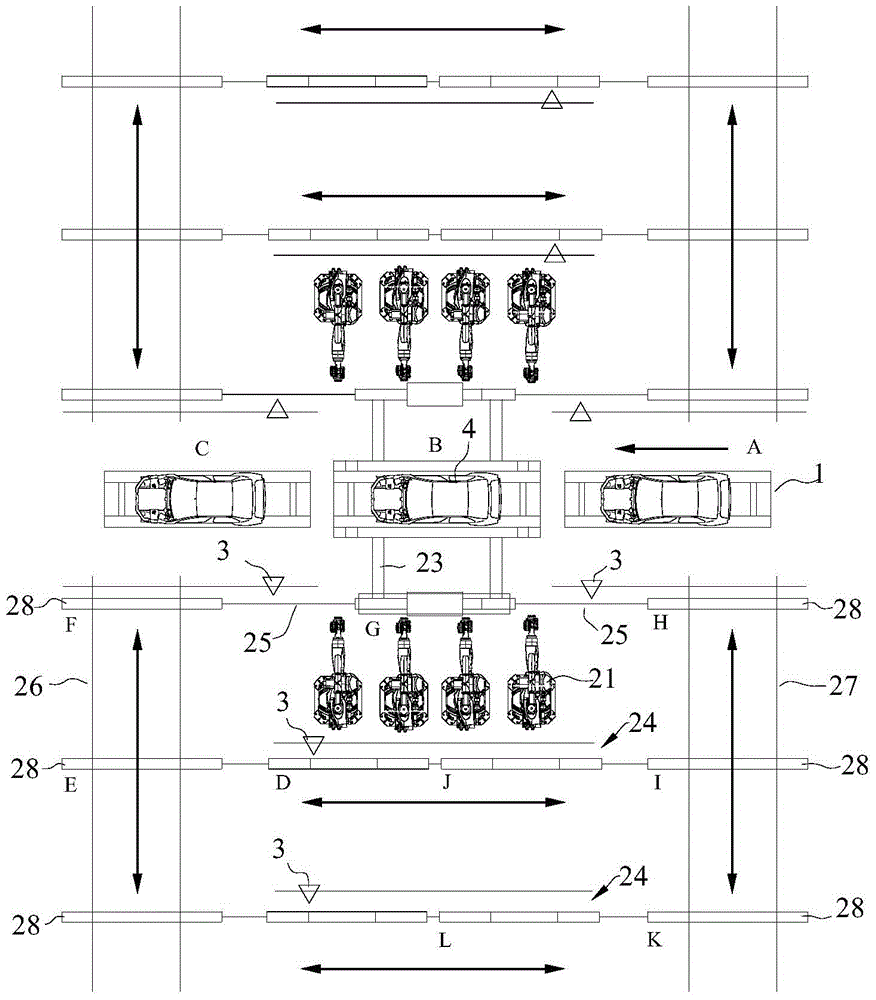

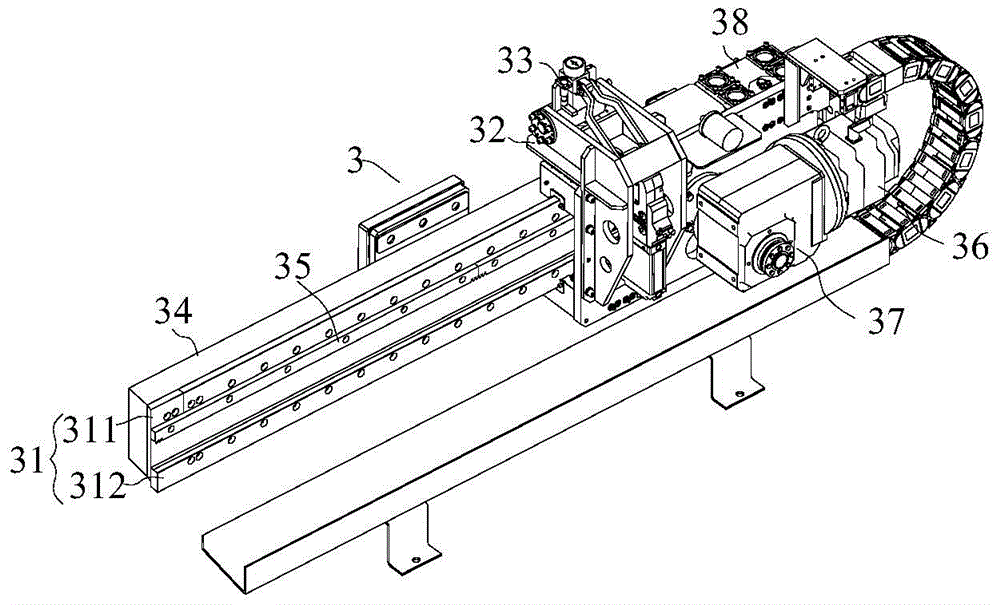

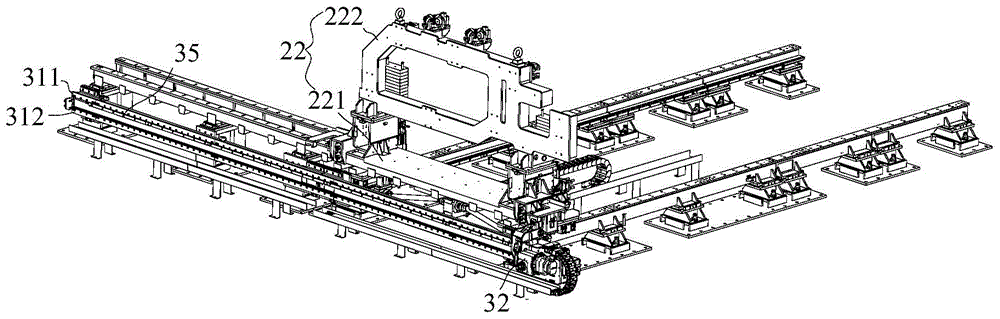

[0016] refer to Figure 1 to Figure 4 , which shows the specific structure of the preferred embodiment of the present invention. The structural characteristics of each element of the present invention will be described in detail below, and if there is a description of the direction (up, down, left, right, front and back), it is based on figure 1 The structure shown is a reference description, but the actual application direction of the present invention is not limited to this.

[0017] The present invention provides a ground-sliding flexible assembly system, including a vehicle body conveying system 1, a floor positioning system, a welding system 21, an assembly fixture 22, an assembly system 23 that drives the assembly fixture 22 to clamp the vehicle body, and clamps The storage system 24 and the fixture switching system that realizes switching of the assembly fixture 22 between the assembly system 23 and the fixture storage system 24, the floor positioning system is mainly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com