Rail transit realizing method and vehicles for method

An implementation method, rail transit technology, applied in the field of rail transit, can solve a large number of problems, difficult to realize line change, high cost of operation and other problems, and achieve the effect of reducing space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

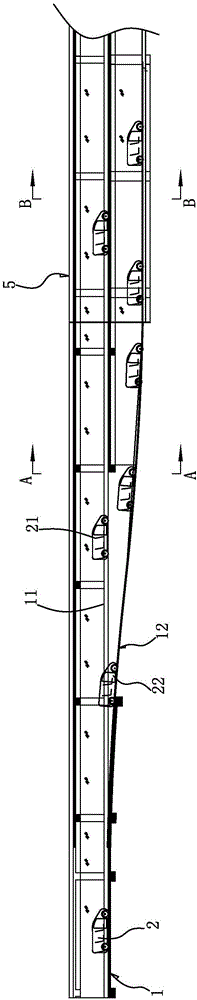

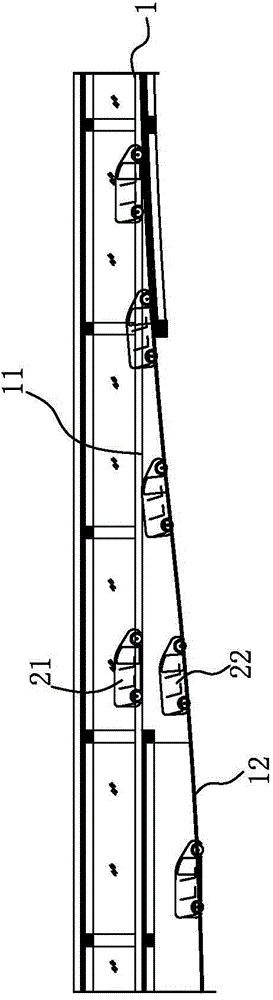

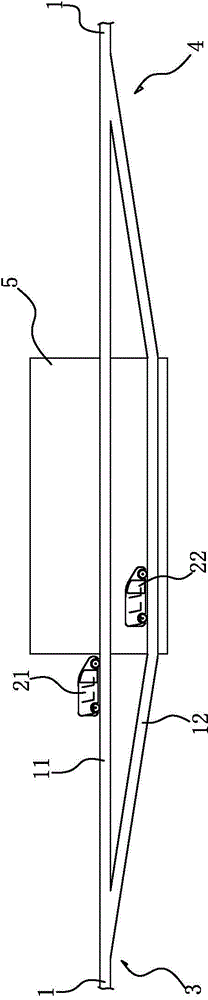

[0038] See Figure 1-6 , combined with Figure 15 As shown, this is Embodiment 1 of the present invention, and what the present invention mainly realizes is how to realize lane change and intersection of vehicles when the vehicles enter the platform.

[0039] The present invention includes: a track 1 and a vehicle 2. Multiple sets of the track 1 can be arranged side by side, and the vehicle 2 runs along the corresponding track 1 in one direction. The track 1 has two rails, and a concave circular arc guide groove 10 is formed on the top of each rail, and the guide groove 10 is used as a guide running groove body of the rail to limit the wheels 20 to run along the guide groove. Vehicle 2 adopts an electric four-wheel rail vehicle with self-propelled power. When it was running, the wheel 20 just fell into the guide groove 10 at the top of the rail, and formed a lateral stabilizing force on the wheel 20 by the guide groove 10. The bottom surface of the inner surface of the guide...

Embodiment approach

[0058] Figure 8The shown structure is the first embodiment of the vehicle 2 of the present invention: in this embodiment, the left and right wheels 23,24 of the vehicle 2 adopt a telescopic structure, that is, the rotating shafts 25, 26 and the shaft sleeve 27 are inserted and fitted. The rotating shaft 27 is used as the transmission shaft of the vehicle 2, and it can be connected with the left and right wheels 23, 24 in a manner similar to spline linkage, so as to realize the transmission of torque. The rotating shafts 25, 26 of the left and right wheels 23, 24 can move horizontally along the axle sleeve 27, so that the wheelbase between the left and right wheels 23, 24 can be changed from L1 to L, or the wheelbase can be changed from L to L1. The way that the rotating shafts 25, 26 move horizontally along the shaft sleeve 27 can be realized by a hydraulic device.

[0059] Second embodiment of vehicle 2:

[0060] See Figure 9 As shown, in this embodiment, the wheels of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com