Assembly room intelligent lighting linkage method and system

A technology of intelligent lighting and linkage system, which is applied in the field of meeting room lighting system, can solve the problem of inconvenient manual operation, and achieve the effect of eliminating the trouble of manual operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

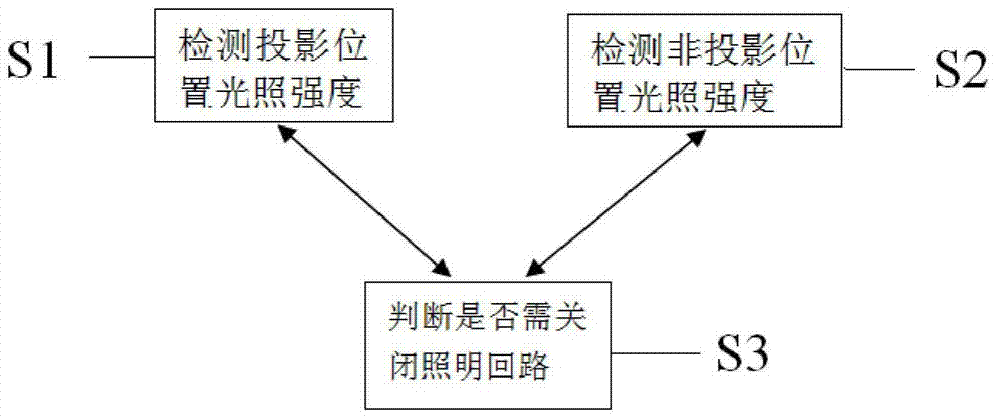

Method used

Image

Examples

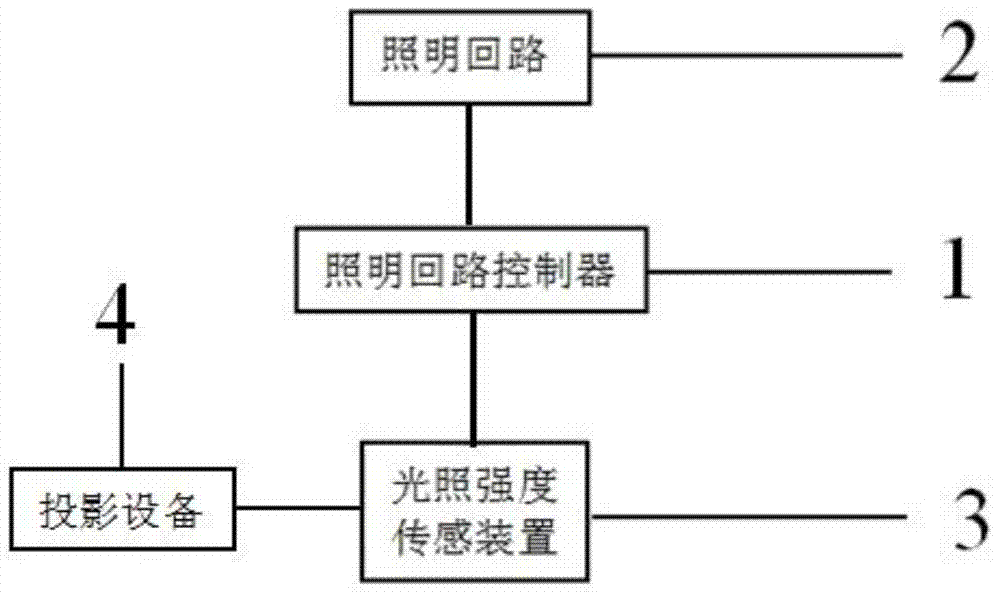

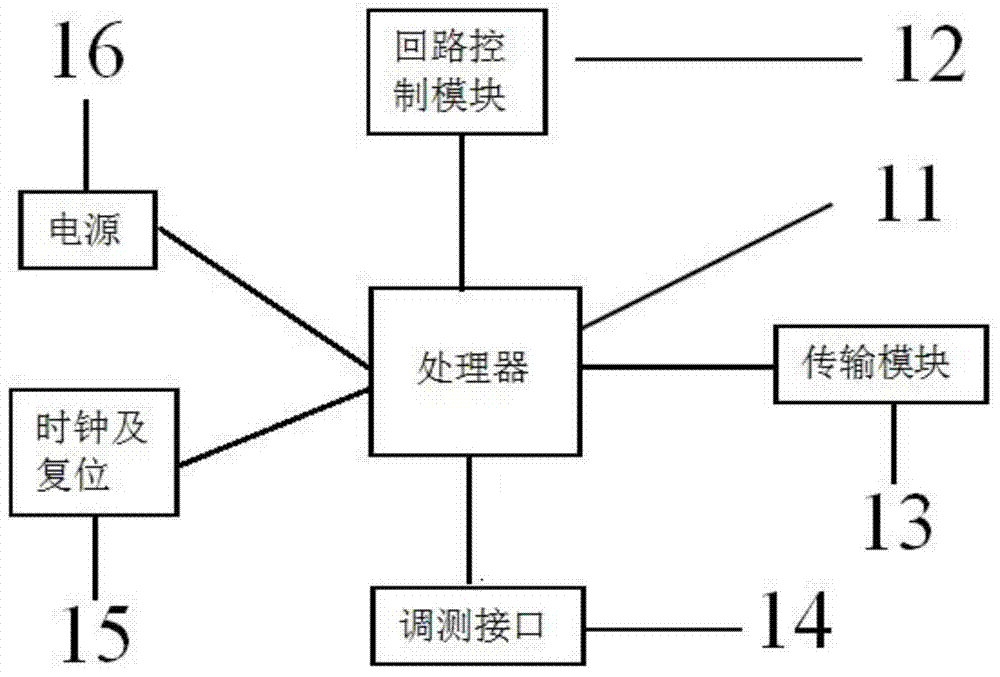

Embodiment 1

[0039] Such as figure 2 , image 3 , Figure 4 and Figure 5 As shown, the conference room intelligent lighting linkage system includes projection equipment 4, the conference room intelligent lighting linkage system includes a light intensity sensing device 3, a lighting loop controller 1 and a lighting loop 2, the light intensity sensing device 3 and The lighting circuit 2 is connected to the lighting circuit controller 1 respectively, and the illumination intensity sensing device 3 includes a projection position illumination intensity sensing device 301 and a non-projection position illumination intensity sensing device 302, and the projection position illumination intensity sensing device The device 301 and the non-projection position light intensity sensing device 302 are respectively connected to the lighting loop controller 1; the lighting loop controller 1 includes a processor 11, a loop control module 12, a transmission module 13, a clock and a reset 15, and Test i...

Embodiment 2

[0042] Such as Figure 6 As shown, the conference room intelligent lighting linkage system includes projection equipment 4, and the conference room intelligent lighting linkage system includes a light intensity sensing device 10 and a lighting circuit 20, and the light intensity sensing device 10 is connected to the lighting circuit 20 and the projection The device 4 is connected, and the illumination intensity sensing device 10 includes a projection position illumination intensity sensor 101, a non-projection position illumination intensity sensor 102 and a processor 103, and the projection position illumination intensity sensor 101 and the non-projection position illumination intensity sensor 102 are respectively connected with The processor 103 is connected; the processor 103 is connected with the lighting circuit 20 .

[0043] The light intensity sensor 101 at the projection position and the light intensity sensor 102 at the non-projection position send the detected light ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com