Door sealing device

A sealing device and sealing strip technology, applied in the direction of sealing device, etc., can solve the problems that the final installation cannot help, the pre-installation position cannot be identified, and the pre-installation of the sealing device is difficult.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

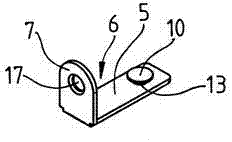

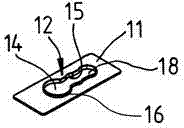

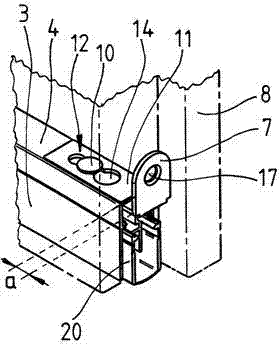

[0030] The door sealing device of the present invention comprises a sealed casing, and a sealing strip 20 that can sink to the bottom is arranged in the sealed casing, and also includes side plates 3, 23 installed on the groove wall 1 on the groove of the door 8, and The side plates 3, 23 are connected to each other and the connecting plate 4, 24 installed on the bottom of the tank 2 also includes a fixed corner plate 6, 26, which has an insertion edge 5, 25 inserted into the sealed casing from the front and is connected to the connecting plate 4. The bottom of 24 is clamped and fixed, and the fixed angle plate 6, 26 has another fixed side 7, 27 which is at right angles to the insertion side. Threaded holes 17, 37 are set in the fixed side 7, 27, and bolts 19 are screwed into the threaded holes 17,37, thereby sealing device is fixed on the door 8.

[0031] as Figure 1~6 As shown, a guide body is installed on the insertion edge 5 in the first fixed angle plate 6, and the shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com