A high-efficiency method for manufacturing a moving iron unit diaphragm

A high-efficiency, moving iron technology, applied in the direction of electrical components, sensors, etc., can solve the problems of low production efficiency, difficult quality assurance, cumbersome production methods, etc., and achieve high processing efficiency, convenient molding, and high product dimensional accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

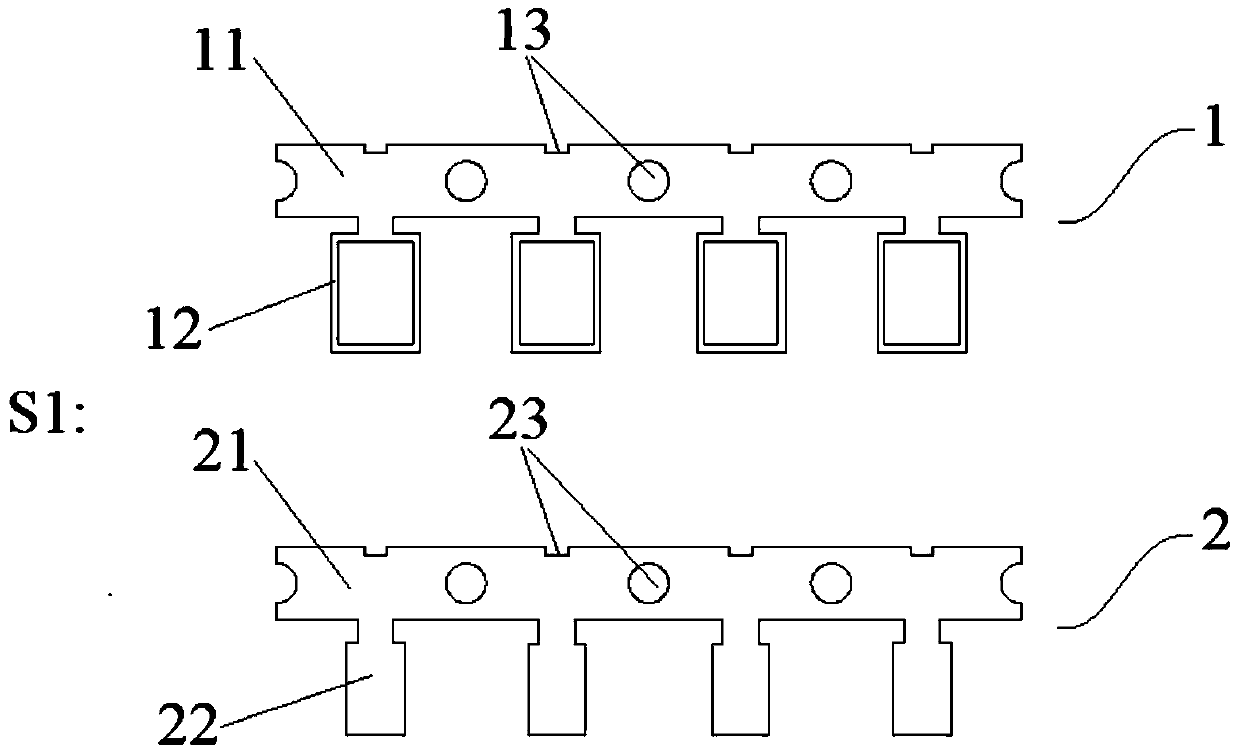

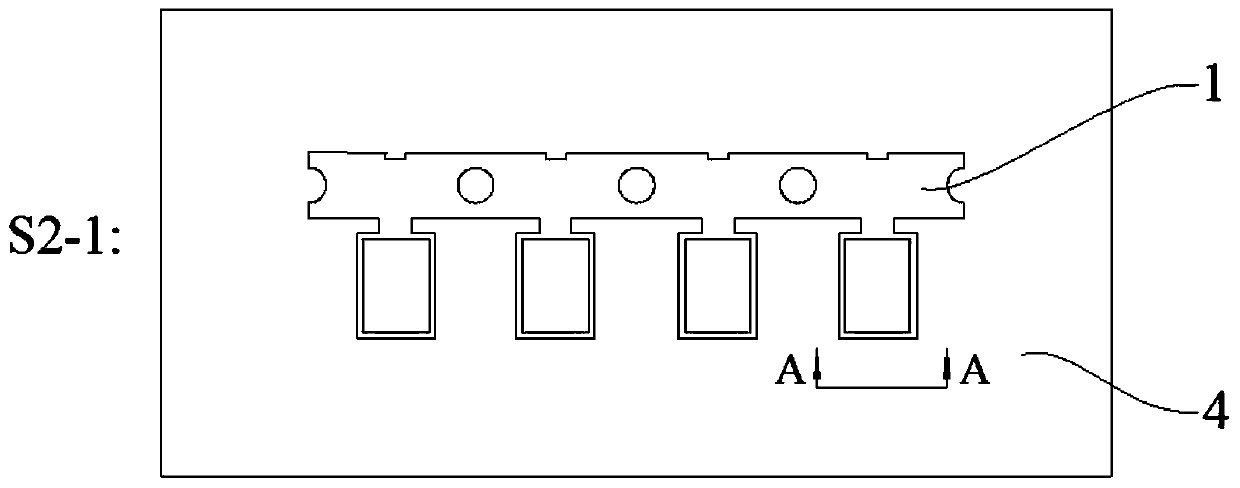

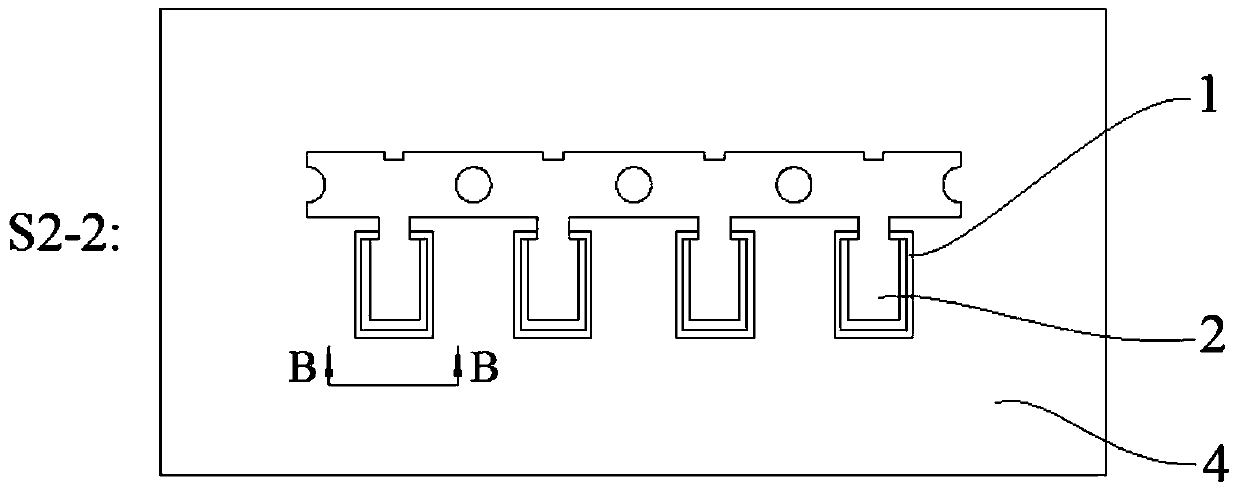

[0047] combine Figure 1 to Figure 5 As shown, a high-efficiency method for manufacturing a moving iron unit diaphragm in this embodiment includes the following process steps:

[0048] S1. Make the diaphragm support sheet group 1 and the diaphragm main sheet group 2, such as figure 1 As shown, the diaphragm support sheet group 1 includes a support strip 11 and two or more diaphragm supports 12 integrally connected to the support strip 11, and both sides of the diaphragm support 12 are formed with folded edges 14 ( see Figure 7 As shown), the bracket strip 11 is also provided with a bracket positioning hole 13, which is used for the positioning of the diaphragm bracket sheet group 1; the diaphragm main body sheet group 2 includes a main body strip 21 and a The diaphragm main body 22 having the same number as the diaphragm support 12 is provided with a main body positioning hole 23 on the main body strip 21 for the positioning of the diaphragm main sheet group 2; specifically...

Embodiment 2

[0059] A high-efficiency method for manufacturing a moving iron unit diaphragm in this embodiment, its process steps are basically the same as in Embodiment 1, the difference is that the diaphragm support 12 in this embodiment is on both sides of the support strip 11, respectively. The spacing is set, and the diaphragm main body 22 is also arranged at equal intervals on both sides of the main material belt 21, that is, the diaphragm support 12 and the diaphragm main body 22 are evenly distributed on both sides of the corresponding material belt according to certain rules, and are not limited to implementation. Single-row design in Example 1; and in this embodiment, four diaphragm supports 12 are arranged at equal intervals on both sides of the support strip 11, and four diaphragm supports are also arranged at equal intervals on both sides of the main body strip 21. The diaphragm main body 22 can complete the production of eight diaphragms 6 in one positioning, and the productio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com