Modularization cylindrical multi-phase permanent magnet linear motor based on single-layer and double-layer mixed windings

A permanent magnet linear motor and hybrid winding technology, applied in electrical components, electromechanical devices, electric components, etc., can solve the problems of high degree of electromagnetic coupling between phases, difficulty in modular design of motors, and difficulty in fault isolation, and achieve power density. Large, good magnetic isolation effect, low manufacturing and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

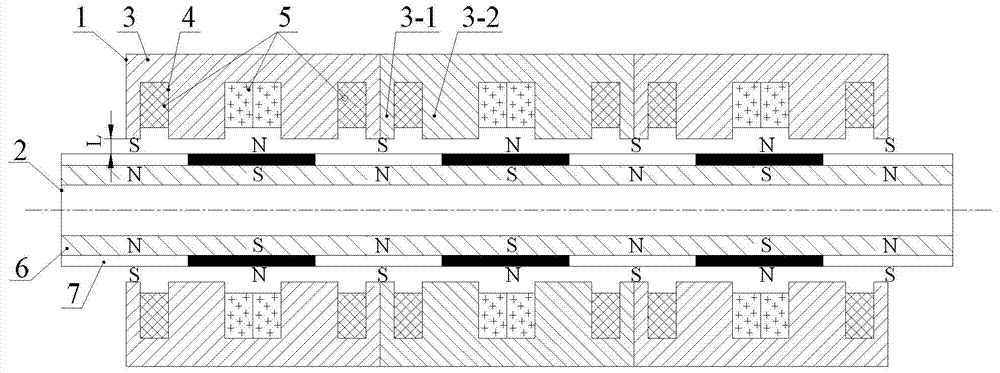

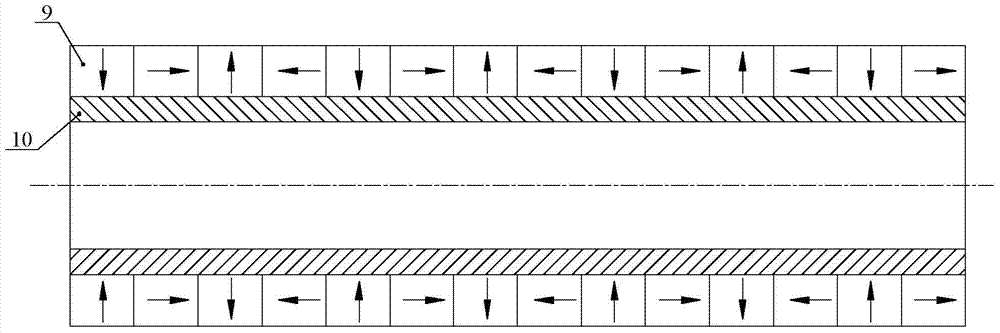

[0016] Specific implementation mode one: the following combination figure 1 and figure 2 This embodiment is described. The modular cylindrical multi-phase permanent magnet linear motor based on the single-layer hybrid winding described in this embodiment includes a stator 1 and a permanent magnet mover 2. The stator 1 is arranged on the side of the permanent magnet mover 2. Internal or external, with a radial air gap of width L between them;

[0017] The stator 1 is assembled from m identical stator modules, and the assembled stator 1 is a cylindrical structure arranged along the axial direction; m is a positive integer;

[0018] Each stator module includes a stator core 3 and 4n annular concentrated windings 5; the stator core 3 is provided with two fault-tolerant teeth 3-1 and 2n armature teeth 3-2, and the length of the armature teeth 3-2 along the axial direction greater than the length of the fault-tolerant tooth 3-1 along the axial direction; n is a positive integer; ...

specific Embodiment approach 2

[0024] Embodiment 2: This embodiment further describes Embodiment 1. The stator 1 has m-phase windings, and all the ring-shaped concentrated windings 5 inside each stator module together form a phase winding. There is no magnetic coupling between the different stator modules.

specific Embodiment approach 3

[0025] Embodiment 3: This embodiment further explains Embodiment 1, m≥3, and the annular concentrated winding 5 is a concentrated winding of three phases or more. The number of winding phases is determined by the number of stator modules.

[0026] By adopting the multi-phase winding, the fault-tolerant operation performance of the modular cylindrical multi-phase permanent magnet linear motor based on the single-layer and double-layer hybrid winding can be improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com