Preparation method of lithium ion battery

A lithium-ion battery and lithium-rich technology, applied in the field of lithium-ion batteries, can solve the problems of poor structural consistency, uncontrollability, and poor cell cycle performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

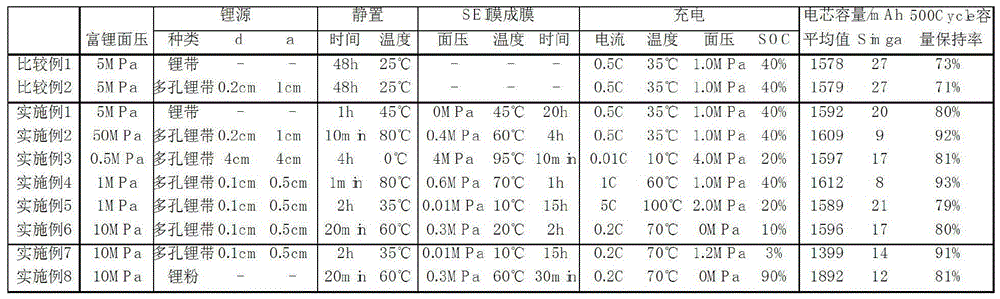

Embodiment 1

[0032] Embodiment 1, different from Comparative Example 1, this embodiment comprises the following steps:

[0033] Preparation of lithium-rich electrode: same as Comparative Example 1.

[0034]Bare cell preparation: choose lithium cobaltate as the cathode active material, stir with conductive agent, binder and nitrogen methylpyrrolidone to obtain a slurry, and then apply it on the aluminum fluid, cold press, slitting, and then use The corona equipment treats the surface of the coating to make the surface of the electrode more conducive to the infiltration of the electrolyte, and then welds, glues, and dries it for use; the separator is treated with ceramic coating to make the surface of the separator more conducive to the electrolyte. Infiltration; and then wind the lithium-rich anode sheet, cathode sheet and the above separator to obtain a bare cell.

[0035] Liquid injection and standing: choose aluminum-plastic film as the packaging material for top-side sealing, and then ...

Embodiment 2

[0039] Embodiment 2, different from Embodiment 1, this embodiment includes the following steps:

[0040] Preparation of lithium-rich electrode: select silicon-carbon composite as the anode active material, stir it with conductive agent, adhesive and deionized water to obtain a slurry, and then coat it on the copper current collector, cold press, slitting, welding, Dry after sticking glue; select porous metal lithium strip as lithium-rich source (equivalent pore diameter, that is, the equivalent diameter d of a single lithium-free region is 0.2cm, and the distance between two holes is the width of the lithium-containing region between the two lithium-free regions a 1cm), using a surface pressure of 50MPa, the metal lithium strips are composited on both sides of the electrode to obtain a lithium-rich electrode sheet.

[0041] Bare cell preparation: choose lithium cobaltate as the cathode active material, stir with conductive agent, binder and nitrogen methylpyrrolidone to obtain...

Embodiment 3

[0046] Example 3, preparation of lithium-rich electrode: select silicon-carbon composite as the anode active material, stir with conductive agent, adhesive and deionized water to obtain slurry, and then apply it on copper current collector, cold press, separate strip, welding, and pasting glue; select the porous metal lithium strip as the lithium-rich source (the equivalent hole diameter is the equivalent diameter d of a single lithium-free region is 4cm, the distance between the two holes is the lithium-containing area between the two lithium-free regions The region width a is 4cm), using a surface pressure of 0.5MPa, the metal lithium strip is composited on both sides of the electrode to obtain a lithium-rich electrode sheet.

[0047] Bare cell preparation: choose lithium cobaltate as the cathode active material, stir with conductive agent, binder and nitrogen methylpyrrolidone to obtain a slurry, and then apply it on the aluminum fluid, cold press, slitting, and then use Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com