Ultrasonic wave angle adjustment device in water immersion ultrasonic testing

An angle adjustment device, ultrasonic testing technology, applied to measuring devices, material analysis using sound waves/ultrasonic waves/infrasonic waves, instruments, etc., can solve the problem of difficult to obtain test results, cannot arrange too many probes and cables, and is difficult to arrange contact probes, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

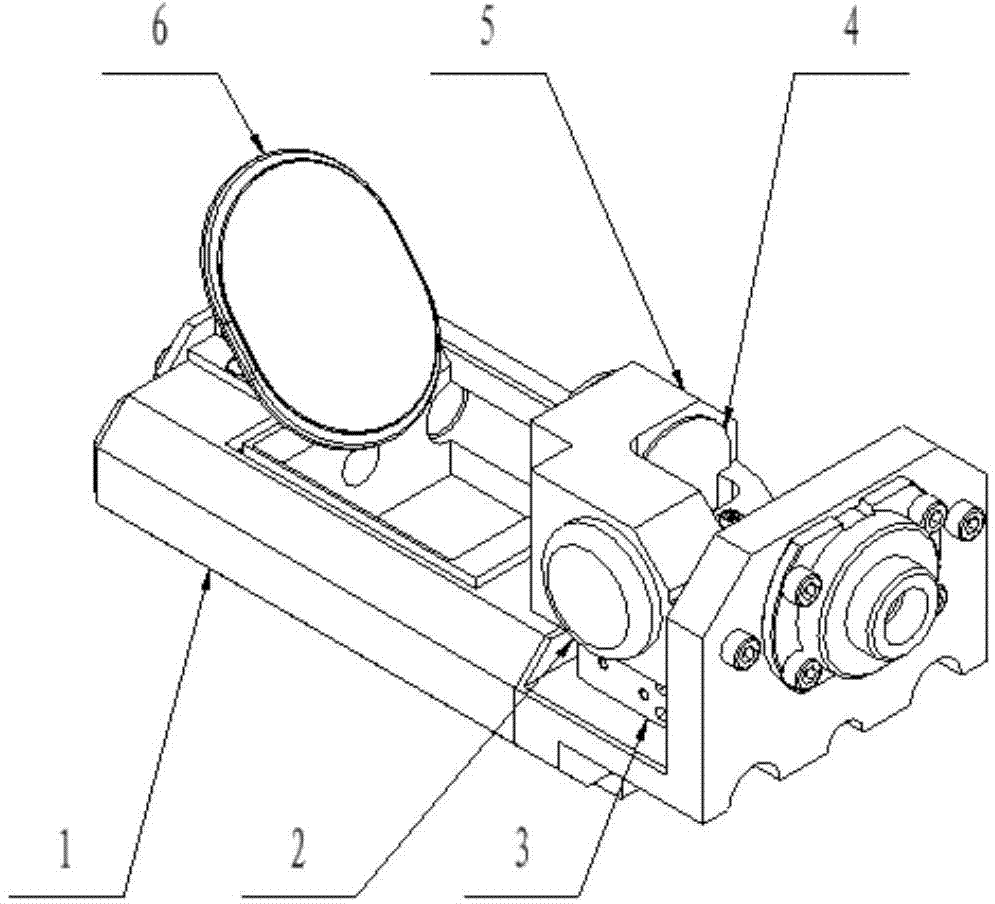

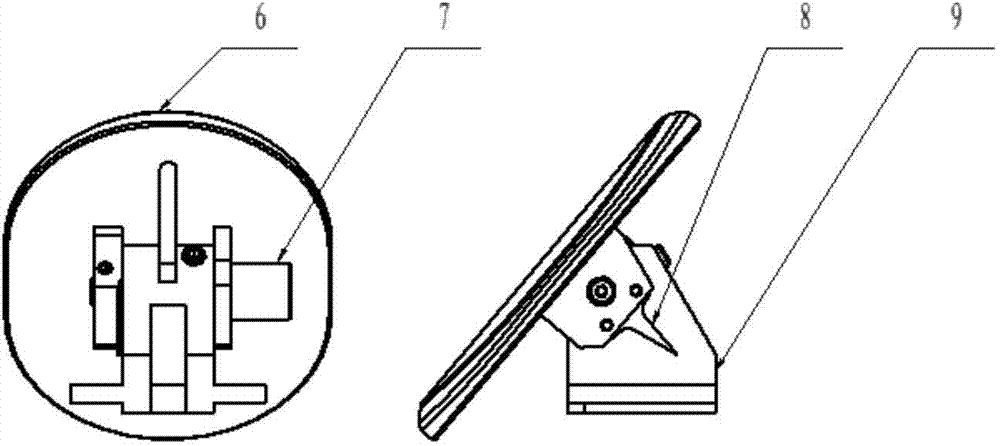

[0016] A device that can remotely control the ultrasonic reflection angle in the water immersion method ultrasonic detection proposed by the patent of the present invention is as follows: figure 1 and figure 2 As shown, it includes: mounting base 1, positioning water immersion probe 2, rotating cylinder 3, quantitative water immersion probe 4, probe holder 5, reflector 6, motor 7, pointer 8, reflector base 9. It can be divided into several functional structures as follows.

[0017] 1) Ultrasonic reflection structure

[0018] The ultrasonic reflection structure includes a positioning water immersion probe 2 , a quantitative water immersion probe 4 and a reflector 6 . During detection, the ultrasonic waves emitted by the positioning water immersion probe 2 or the quantitative water immersion probe 4 are reflected by the mirror 6 to increase the water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com