Automatic analysis device

An automatic analysis device and operation technology, applied in the direction of analyzing materials, office automation, healthcare resources or facilities, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

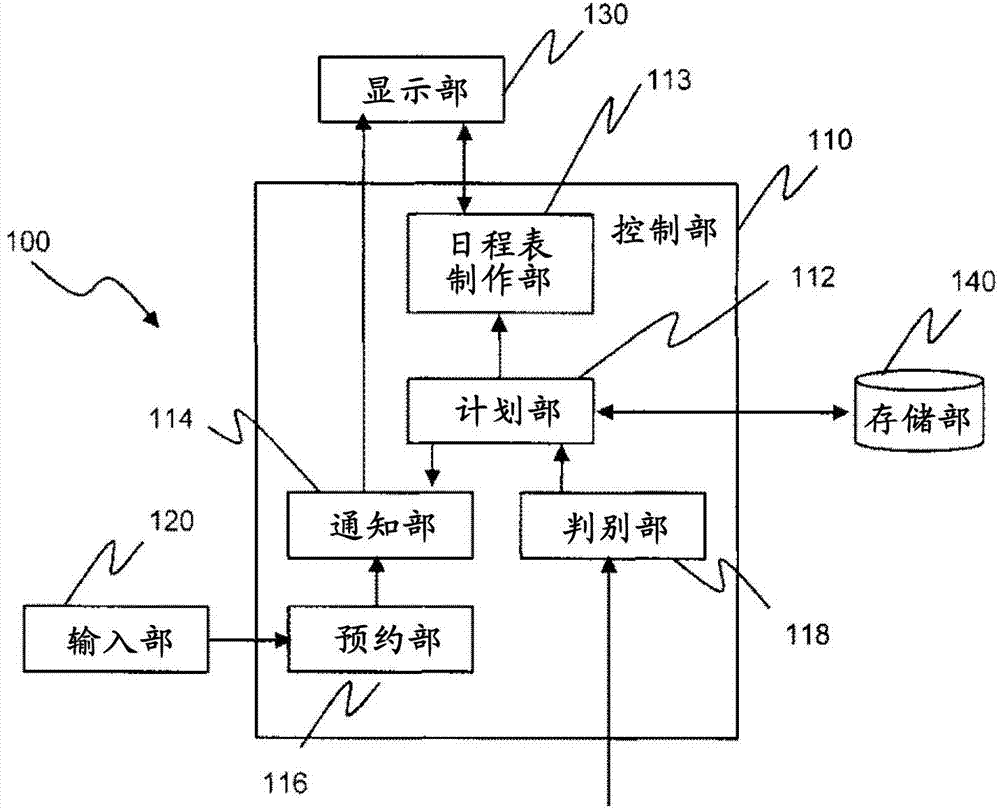

[0030] Below, use Figure 1 to Figure 9 , the configuration and operation of an automatic analyzer according to one embodiment of the present invention will be described.

[0031] First, use figure 1 The overall configuration of the automatic analyzer of this embodiment will be described.

[0032] figure 1 It is a system configuration diagram showing the overall configuration of an automatic analyzer according to an embodiment of the present invention.

[0033] The automatic analyzer of this embodiment includes, for example, three analysis units AA1 , AA2 , and AA3 arranged in series. In addition, the number of analysis units is not limited to three, and may be multiple or single. A transport line TRL for transporting sample racks is provided adjacent to the analysis units AA1 , AA2 , and AA3 . Furthermore, a sample input unit SAI is provided at one end of each of the analysis units AA1 , AA2 , and AA3 arranged in series, and a sample storage unit SAO is provided at the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com