Load sensor monitoring method and system

A load sensor and load capacity technology, which is applied in construction and other fields, can solve the problems of inaccurate data collection of light rod indicator diagrams and difficulty in finding load sensors in time, so as to improve the production operation and management level, and the identification method is simple and feasible. Guarantee the effect of collection quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

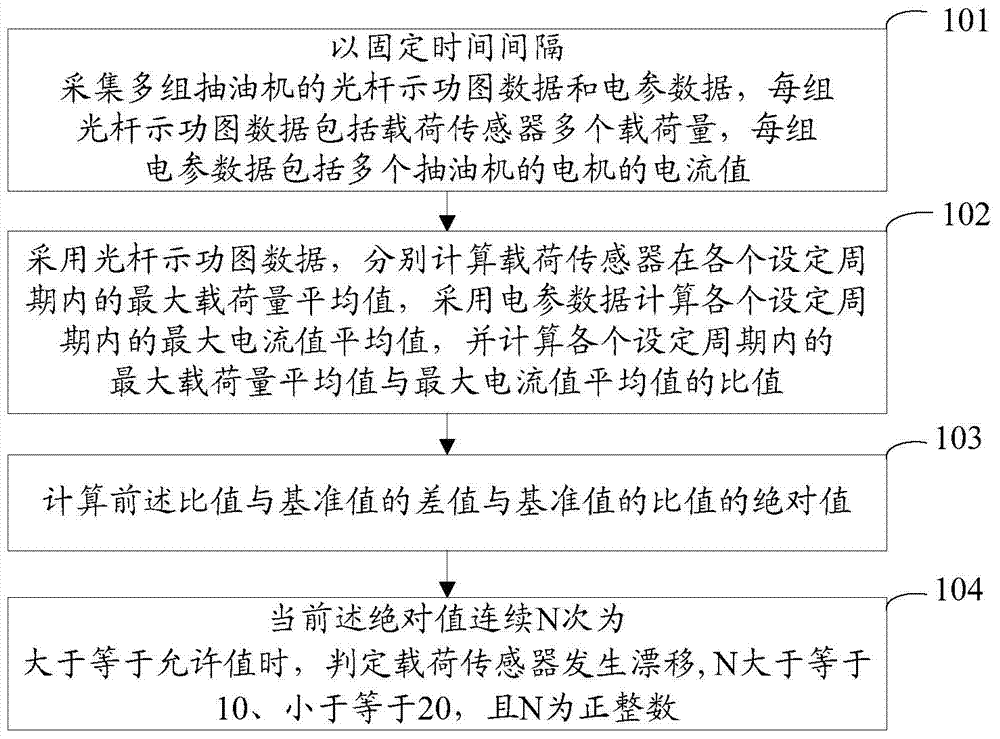

[0048] The embodiment of the present invention provides a load sensor monitoring method, the load sensor is suitable for measuring the load of the sucker rod of the pumping unit, see figure 1 , the method includes:

[0049]Step 101: Collect multiple sets of polished rod dynamometer data and electrical parameter data of the pumping unit at fixed time intervals, each set of polished rod dynamometer data includes multiple loads measured by the load sensor, and each set of electrical parameter data includes multiple The current value of the motor of the pumping unit.

[0050] Among them, the polished rod indicator diagram data also includes multiple displacement values of the pumping unit that are measured synchronously with the load. The load is measured by the load sensor installed on the pumping unit, and the displacement value is measured by the displacement sensor installed on the pumping unit. Measured. The electrical parameter data can be measured by a current transform...

Embodiment 2

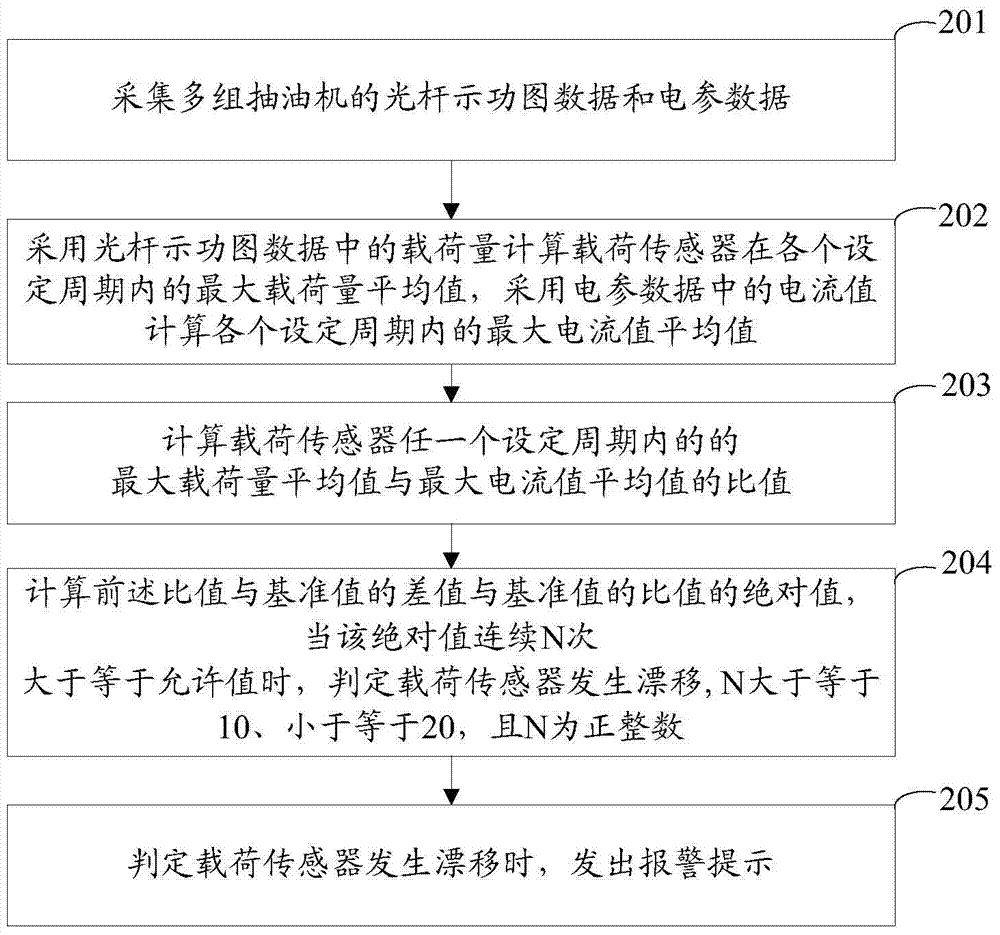

[0059] The embodiment of the present invention provides a load sensor monitoring method, the load sensor is suitable for measuring the load of the sucker rod of the pumping unit, see figure 2 , the method includes:

[0060] Step 201: Collect polished rod dynamometer data and electrical parameter data of multiple groups of pumping units.

[0061] Wherein, each set of polished rod dynamometer data includes multiple loads measured by the load sensor, and each set of electric parameter data includes current values of motors of multiple pumping units. The polished rod indicator diagram data also includes multiple displacement values of the pumping unit that are measured synchronously with the load. The load is measured by the load sensor installed on the pumping unit, and the displacement value is measured by the displacement sensor installed on the pumping unit. .

[0062] Preferably, the electrical parameter data is collected by a current transformer. The displacement sen...

Embodiment 3

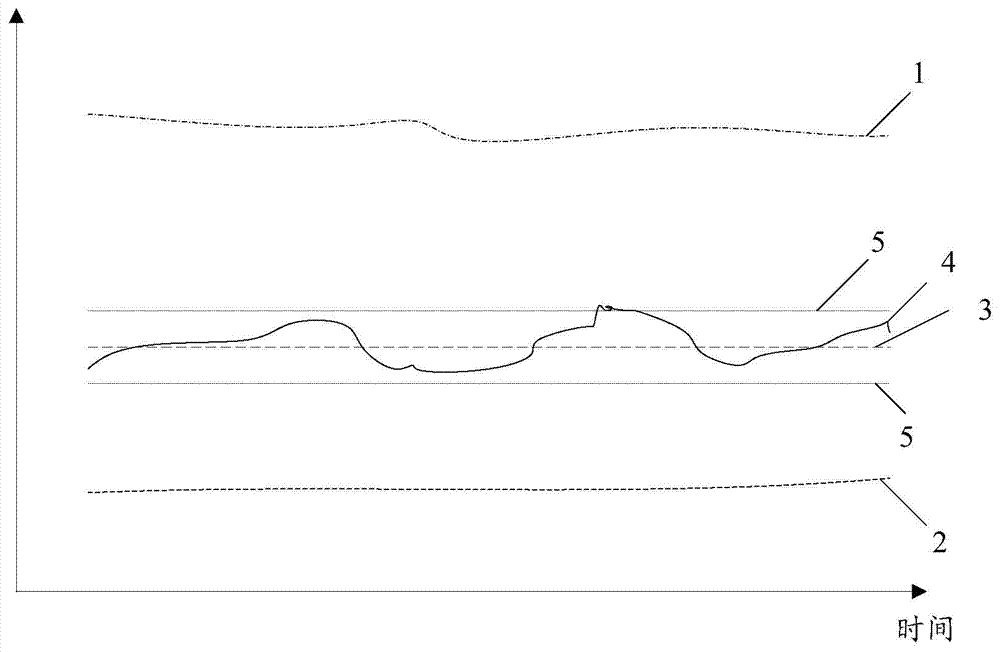

[0095] An embodiment of the present invention provides a load sensor monitoring system, the load sensor is suitable for measuring the load of the sucker rod of the pumping unit, see image 3 , the system includes: a wellhead collector 31 and a host computer 32.

[0096] Wherein, the wellhead collector 31 is used for collecting polished rod dynamometer data and electrical parameter data of multiple groups of pumping units at fixed time intervals. Each set of polished rod dynamometer data includes multiple loads measured by the load sensor, and multiple displacement values of the pumping unit measured synchronously with the loads, and the displacement values are measured by the displacement sensor installed on the pumping unit. Each set of electrical parameter data includes current values of motors of multiple pumping units. The current data can be measured by a current transformer.

[0097] The upper computer 32 is used to calculate the average value of the maximum load...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com