Platform Calibration Clips

A platform calibration and conductive clip technology, applied in the field of platform calibration clips, can solve problems such as interfering with the normal operation of 3D printers, occupying effective printing space, and single clamping function, and achieves convenient plane clamping functions and calibration functions, high practicability and promotion value, the effect of flexible elicitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

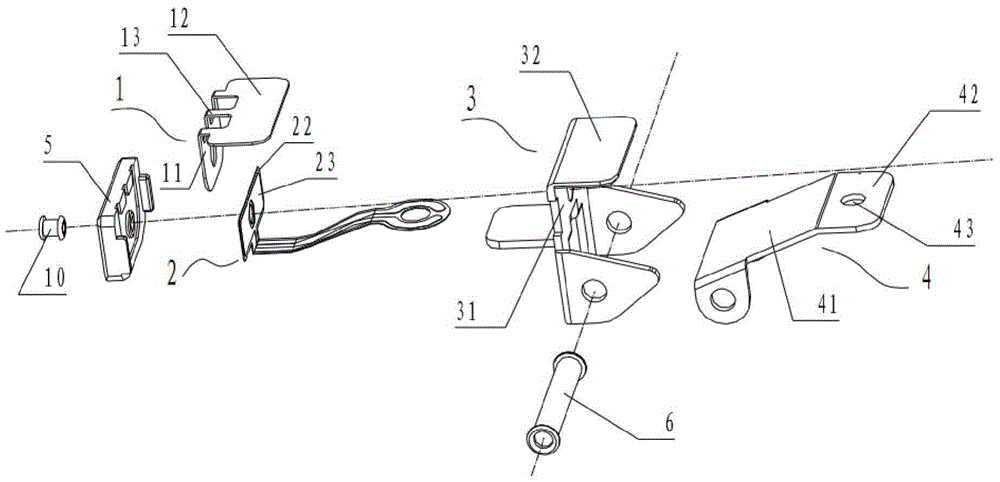

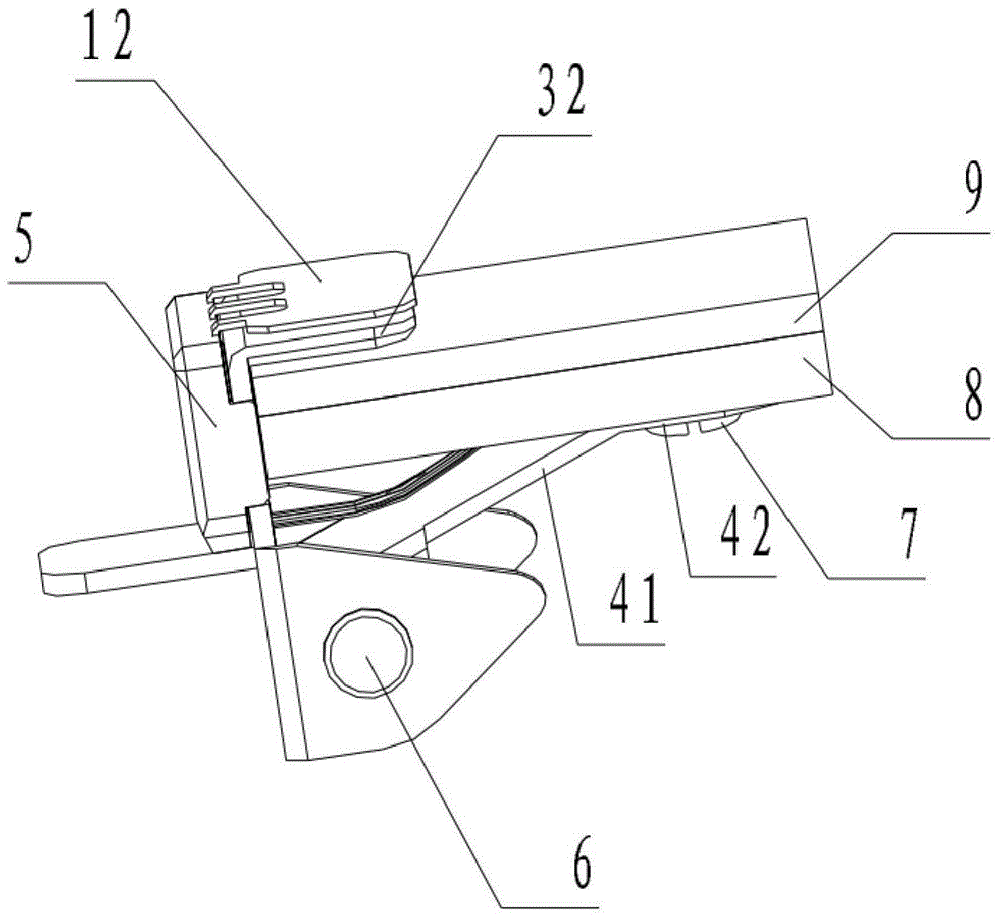

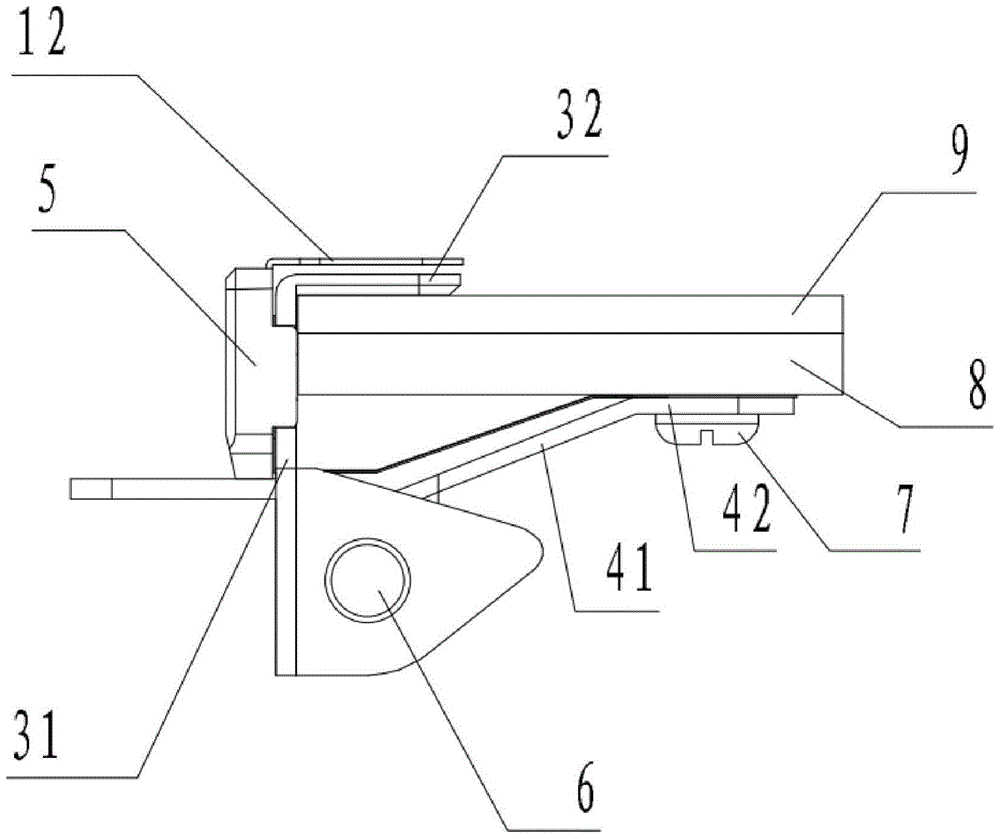

[0028] Example 1 : The schematic assembly diagram of the structure of the present embodiment 1 is as follows figure 1 As shown, the schematic three-dimensional view of the structure clamped on the 3D printing platform is shown in figure 2 As shown, the schematic front view of the structure is shown in image 3 As shown, the structure schematic left view is as follows Figure 4 as shown, Figure 4 The A-A sectional view is as follows Figure 5 As shown, it includes a conductive metal shrapnel 1, a flexible circuit board 2 and a clip for clamping.

[0029] The clip includes a conductive clamping body 3 and a clamping elastic piece 4 adapted for clamping. The conductive clamping body 3 includes a first main body 31 and a first clamping part 32 connected to the first main body. , the clamping elastic piece 4 includes a second clamping portion 42 parallel to the first clamping portion 32 , and an extending elastic piece extending from the second clamping portion 42 and til...

Embodiment 2

[0038] Example 2: The structure is basically the same as that of Embodiment 1, and the similarities are no longer repeated, but the difference is:

[0039] When the rivet or bolt passes through the perforation on the flexible circuit board 2 and the first main body portion 31 of the conductive clamping body, it is insulated from the flexible circuit board 2 and the first main body portion 31 of the conductive clamping body. Of course, it is also possible that the rivets or bolts are all insulated from the passing parts. For example, the rivets or bolts are plastic parts, or the rivets or bolts are metal parts, but they have been subjected to insulation treatment similar to that of Embodiment 1 when passing through each component. In short, as long as the rivets or bolts are not conductive to the first conductive layer and the second conductive layer through which they penetrate, it is sufficient.

[0040] In the second embodiment, the second contact portion 12 is a second c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com