Method of recognizing asynchronous vibration parameters of blades under variable speed excitation

A technology of vibration parameters and identification methods, which is applied in the direction of measuring vibration, vibration measurement in solids, and measuring devices, and can solve problems such as difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

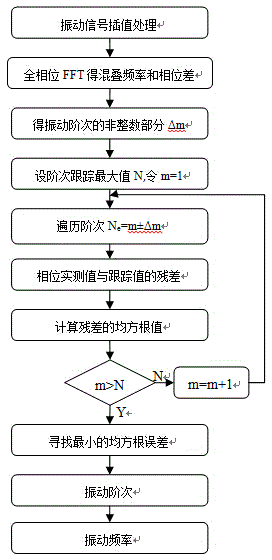

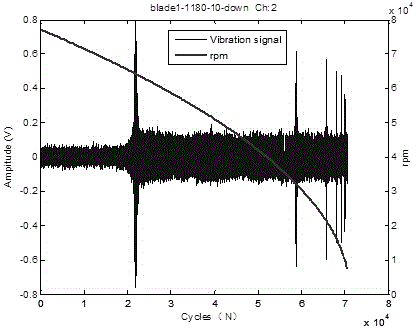

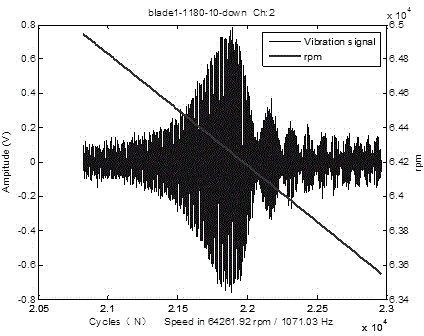

[0024] The method for identifying asynchronous vibration parameters of blades under variable speed excitation proposed by the present invention will be described in detail below in conjunction with the accompanying drawings.

[0025] The single-blade single-degree-of-freedom vibration displacement equation can be expressed as:

[0026]

[0027] Among them: A is the vibration amplitude, is the initial phase, i=0,1,2,...,M-1, M is the number of sensors, t i Sampling interval.

[0028] Because the vibration frequency of the blade is a non-integer multiple of the rotational speed, ω=(m+Δm)Ω, (m+Δm) is the asynchronous vibration order, where m is a positive integer, Δm is a decimal between 0 and 1, and Ω is speed frequency, and let t i =(θ i +2πn) / Ω, θ i is the installation angle of the sensor, and n is the number of rotations. Therefore, formula (1) can be transformed into:

[0029]

[0030] in And Δm=Δω / Ω, Δω is the aliasing frequency, substituting into formula (2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com