Torque test machine

A technology of torque testing and testing department, applied in the field of torque testing machines, can solve problems such as inaccurate test results, low test efficiency, and difficulty in applying force with a wrench, and achieve the effects of improving test efficiency, accurate torque value, and average torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

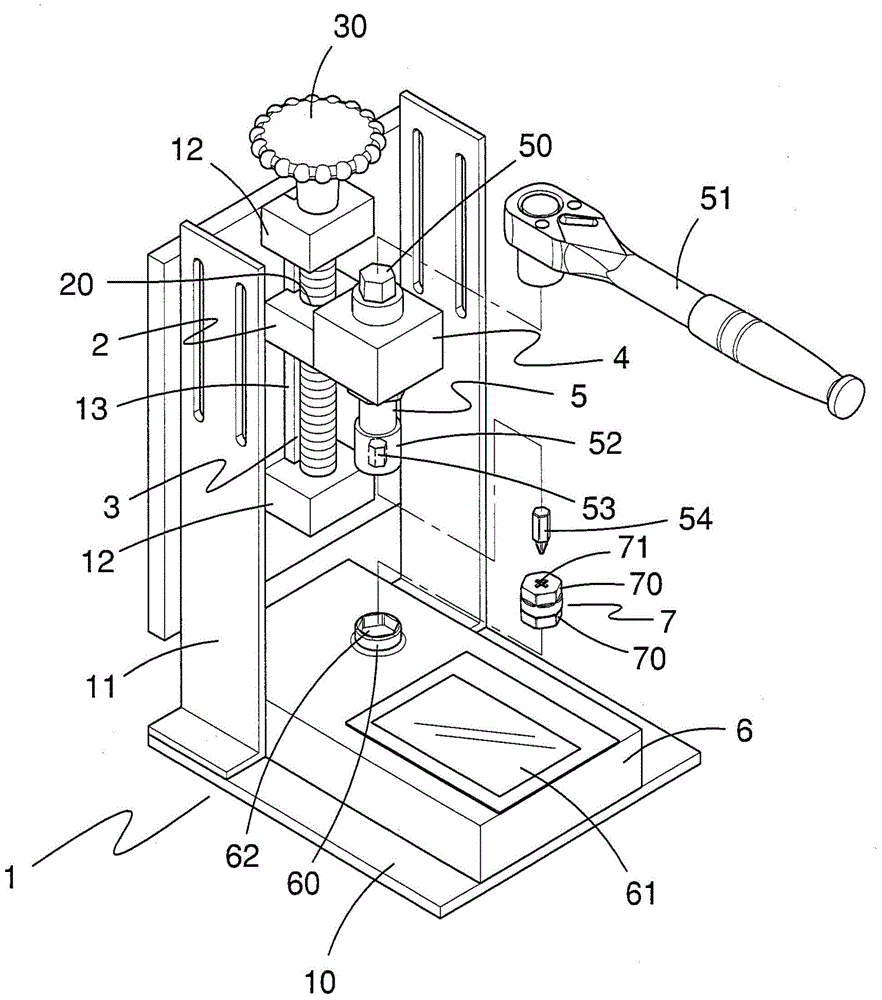

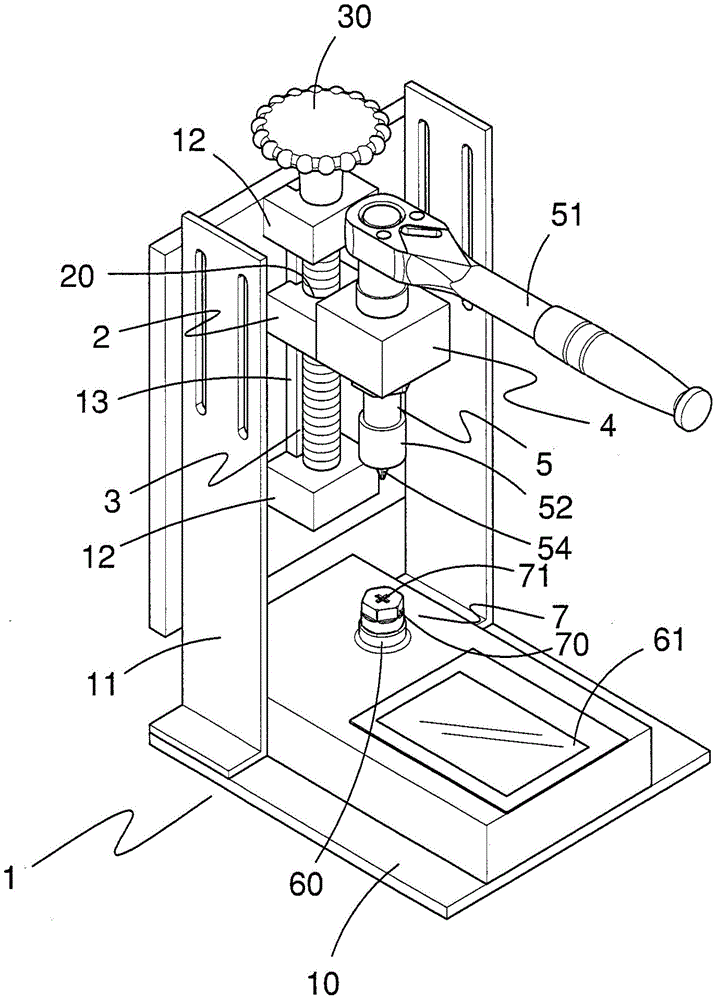

[0010] Such as Figure 1-3 It shows that the torque testing machine of the present invention includes a machine platform 1 , a movable block 2 , a lead screw 3 , a bump 4 , a shaft 5 , a torque testing device 6 and a jig 70 . Wherein: the machine table 1 has a base body 10 and a frame body 11 standing on the base body 10 . The frame body 11 has two fixing blocks 12 and a guide rail 13 on one side thereof. The two fixing blocks 12 are vertically separated by a certain distance, and the guide rail 13 is located between the two fixing blocks 12 and perpendicular to the base body 10 . The movable block 2 is movably combined with the guide rail 13 , and can move up and down between the two fixed blocks 12 . The movable block 2 has a threaded hole 20 through the upper and lower. The lead screw 3 is rotatably coupled to the two fixing blocks 12 perpendicular to the base 10 . The lead screw 3 passes through the screw hole 20 of the movable block 2 and is screwed into the screw hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com