Module type secondary vibration isolator

A vibration isolator, modular technology, applied in the direction of non-rotation vibration suppression, etc., can solve the problems of large floor space, poor structural integrity, too large, etc., and achieve the effect of low natural frequency, light volume, and small footprint.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

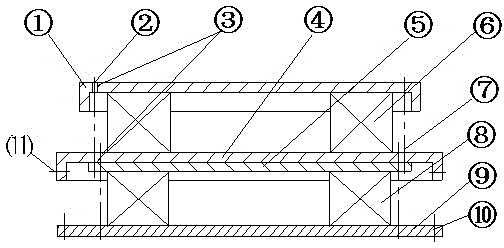

[0026] As shown in the drawings, a modular secondary vibration isolator includes an upper cover plate 1 connected to a mass frame plate 4 through upper fastening bolts 2, with an upper elastic element 6 sandwiched in the middle, and a bottom plate 9 through lower fastening bolts 7 It is connected with the mass frame plate 4 with a lower elastic element 8 in between, and the upper and lower elastic elements and the mass frame plate form a secondary vibration isolation system; the mass frame plate 4 is fixed with a detachable and replaceable mass plate 5 . Reinforcing ribs are provided around the upper cover plate 1 and the mass frame plate 4 . The total mass of the mass shelf plate 4 and the interchangeable mass plate 5 is determined according to actual needs, and an exchangeable mass plate 5 of suitable quality is selected. The quality frame plate 4 is a lightweight structure. One end of the upper fastening bolt 2 is fixed to the mass frame plate 4 by the screw hole, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com