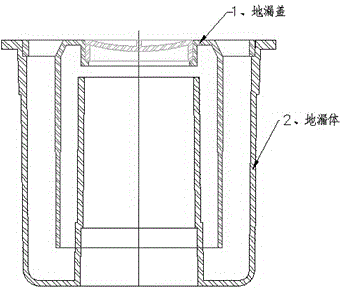

Water seal deodorant floor drain with float ball

A floor drain and floating ball technology, which is applied to waterway systems, water supply devices, drainage structures, etc., can solve problems such as difficult demoulding, increased mold manufacturing costs, and complex design of molding mold demoulding mechanisms, achieving simple structure and fast water flow Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

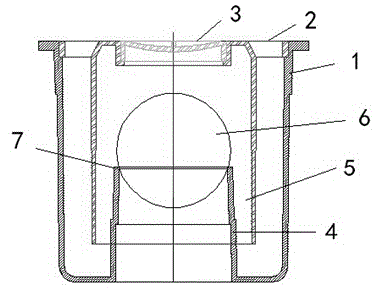

[0017] Such as figure 2 As shown, a floating ball water seal deodorant floor drain is disclosed, including a floor drain body, a floor drain cover, a floor drain inner cover, a water storage column, a water outlet and a floating ball, the floor drain cover is covered on the floor drain body, and the water storage column is arranged on the floor drain body Inside, the floor drain cover forms a water storage area, the drain is located above the water storage, a floating ball is placed on the drain, the height of the floor drain body is twice the height of the water storage column, the floor drain cover is a hollow cylinder, and The diameter is 1.5 times the diameter of the drain, the diameter of the floating ball is 1.1 times the diameter of the drain, and is smaller than the diameter of the floor drain cover, the diameter of the inner cover of the floor drain is smaller than the diameter of the float, and the drain There is a soft rubber surface on the mouth.

Embodiment 2

[0019] Disclosed is a floating ball water-sealed deodorant floor drain, comprising a floor drain body, a floor drain cover, a floor drain inner cover, a water storage column, a water outlet and a floating ball, the floor drain cover is covered on the floor drain body, the water storage column is arranged inside the floor drain body, and The floor drain cover forms a water storage area, and the drain outlet is located above the water storage housing. A floating ball is placed on the drain outlet. The height of the floor drain body is three times the height of the water storage column. The floor drain cover is a hollow cylinder with a diameter of 1.6 times the diameter of the mouth, the diameter of the floating ball is 1.4 times the diameter of the drain, and is smaller than the diameter of the floor drain cover, the diameter of the inner cover of the floor drain is smaller than the diameter of the float, and the drain is provided with Soft rubber surface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com