Flavored Low Sodium Seasoning Salt

A seasoning salt and flavor peptide technology, applied in the field of low-sodium seasoning salt, can solve the problems of high sodium and low potassium, and achieve the effect of high nutritional value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

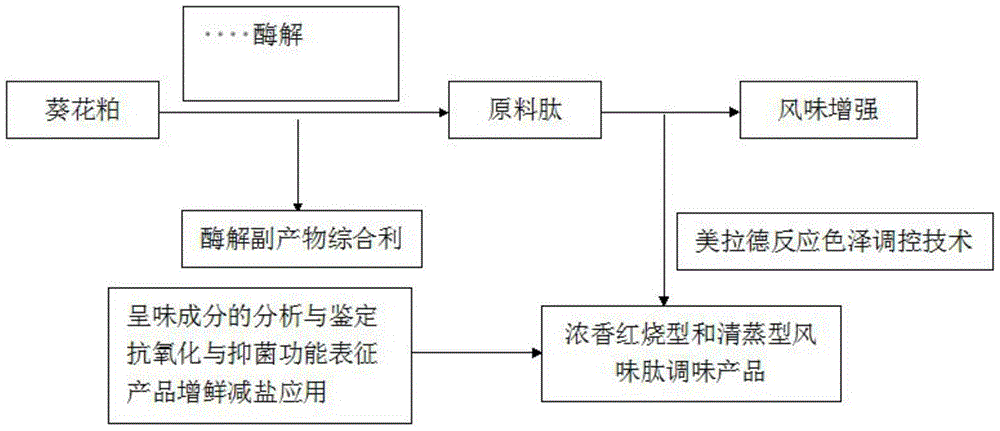

Method used

Image

Examples

Embodiment 1

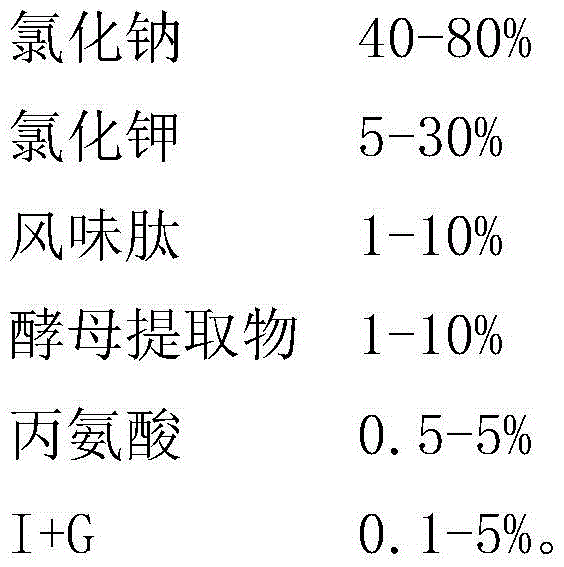

[0037] A low-sodium seasoning salt with taste, made of the following raw materials in weight percentage:

[0038]

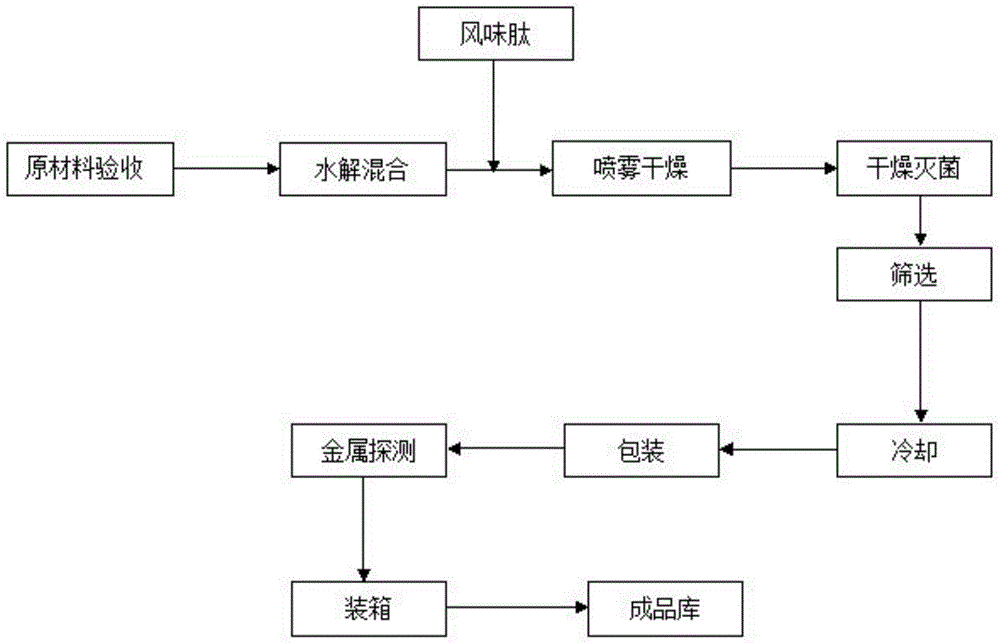

[0039] The preparation method of above-mentioned taste low-sodium seasoning salt is as follows (see figure 1 ):

[0040] 1) Carry out raw material acceptance and proportioning of sodium chloride, potassium chloride, flavor peptide, yeast extract, alanine and I+G according to the above proportioning;

[0041] 2) Dissolve sodium chloride, potassium chloride, yeast extract, alanine and I+G in deionized water, heat up to 85°C, stir at a speed of 300r / min until completely dissolved, and prepare the weight of dry matter A solution with a concentration of 35%-45%;

[0042] 3) After the solution is cooled to 40°C, add the flavor peptide under stirring at a speed of 300r / min, and after stirring for 10 minutes at a speed of 300r / min, immediately use a centrifugal spray drying tower for spray drying. 145-155°C, the outlet air temperature is 95-105°C, to obtain granula...

Embodiment 2

[0053] A low-sodium seasoning salt with taste is characterized in that it is made from the following raw materials in percentage by weight:

[0054]

[0055] The preparation method of above-mentioned taste low-sodium seasoning salt is as follows (see figure 1 ):

[0056] 1) Carry out raw material acceptance and proportioning of sodium chloride, potassium chloride, flavor peptide, yeast extract, alanine and I+G according to the above proportioning;

[0057] 2) Dissolve sodium chloride, potassium chloride, yeast extract, alanine and I+G in deionized water, heat up to 85°C, stir at a speed of 300r / min until completely dissolved, and prepare the weight of dry matter A solution with a concentration of 35%-45%;

[0058] 3) After the solution is cooled to 40°C, add the flavor peptide under stirring at a speed of 300r / min, and after stirring for 10 minutes at a speed of 300r / min, immediately use a centrifugal spray drying tower for spray drying. 145-155°C, the outlet air tempera...

Embodiment 3

[0068] A low-sodium seasoning salt with taste, made of the following raw materials in weight percentage:

[0069]

[0070] The preparation method of above-mentioned taste low-sodium seasoning salt is as follows (see figure 1 ):

[0071] 1) Carry out raw material acceptance and proportioning of sodium chloride, potassium chloride, flavor peptide, yeast extract, alanine and I+G according to the above proportioning;

[0072] 2) Dissolve sodium chloride, potassium chloride, yeast extract, alanine and I+G in deionized water, heat up to 85°C, stir at a speed of 300r / min until completely dissolved, and prepare the weight of dry matter A solution with a concentration of 35%-45%;

[0073] 3) After the solution is cooled to 40°C, add the flavor peptide under stirring at a speed of 300r / min, and after stirring for 10 minutes at a speed of 300r / min, immediately use a centrifugal spray drying tower for spray drying. 145-155°C, the outlet air temperature is 95-105°C, to obtain granula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com