Dumper stress reserving carriage expansion prevention assembling and welding technology

A technology for carriage groups and dump trucks, which is applied to vehicle components, manufacturing tools, welding equipment, etc., can solve the problems of rising outside the carriage, reducing the carrying capacity of the carriage, affecting the safety of carriage transportation, and achieving the effect of convenient maintenance and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

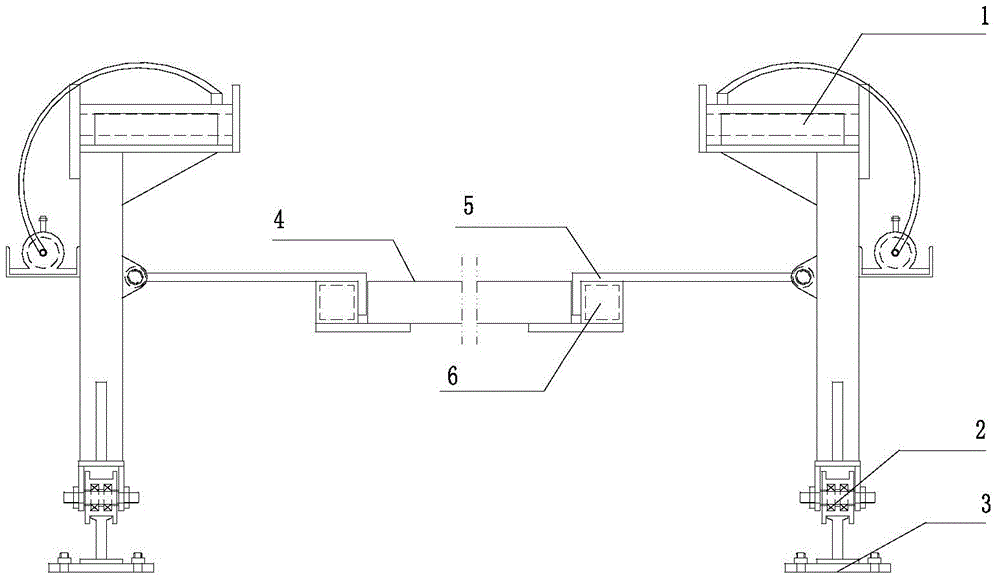

[0015] A process for assembling and welding a dump truck with reserved stress-inflated anti-expansion compartment mainly includes the following steps:

[0016] (1) Determine the position where the side panel of the carriage receives the maximum lateral force. After the finite element analysis, it is clear that the front 1 / 4 of the side panel of the carriage (viewed from the front to the rear) is the easiest position to expand the compartment.

[0017] (2) Reserve the deformation stress of the side plate assembly, reverse the deformation of the side plate assembly at the maximum lateral force through the special pad and pressure mechanism, and then weld the side plate so that after the side plate is welded, the front end 1 / The 4 places have the largest lateral stress.

[0018] Place a special pad on the left and right sides of the 1 / 4 position of the side plate of the carriage, use the gantry compression frame to apply pressure on the 1 / 4 of the side plate of the carriage, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com