Constant-volume gas-bearing coal gas-solid coupling physical and mechanical parameter testing device and testing method

A technology of mechanical parameters and test device, applied in the field of geotechnical engineering scientific research and mining engineering, can solve the problems of single function, complicated operation, difficult to realize the visual real-time monitoring of the test process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

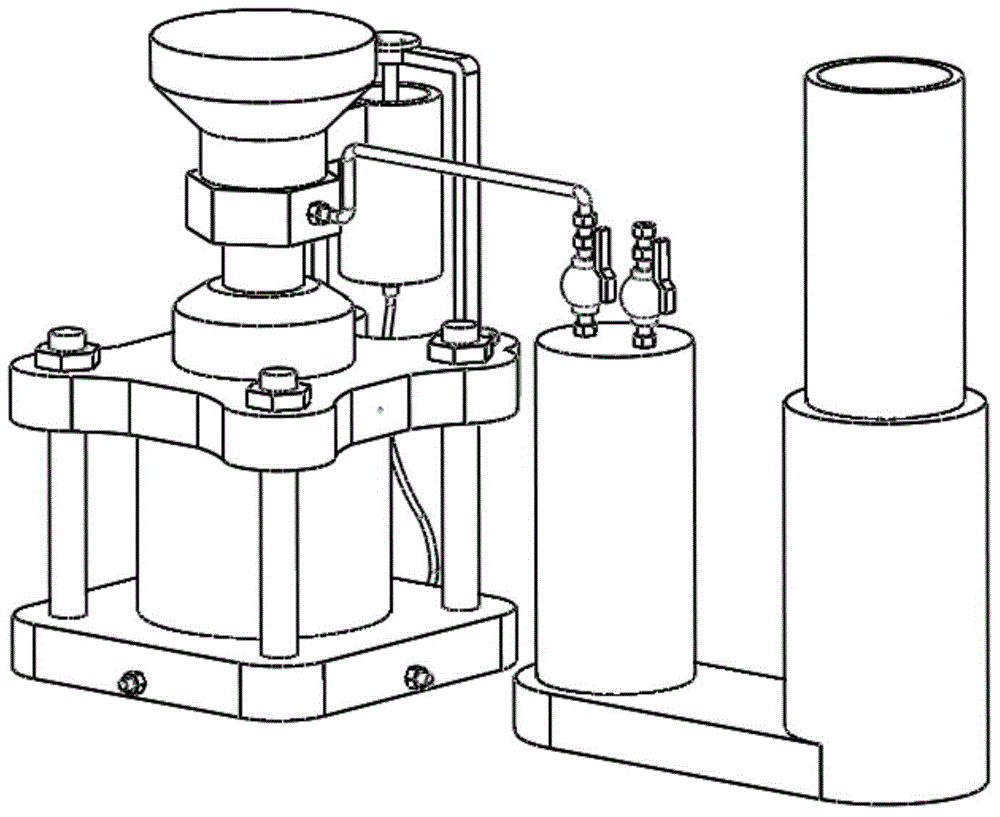

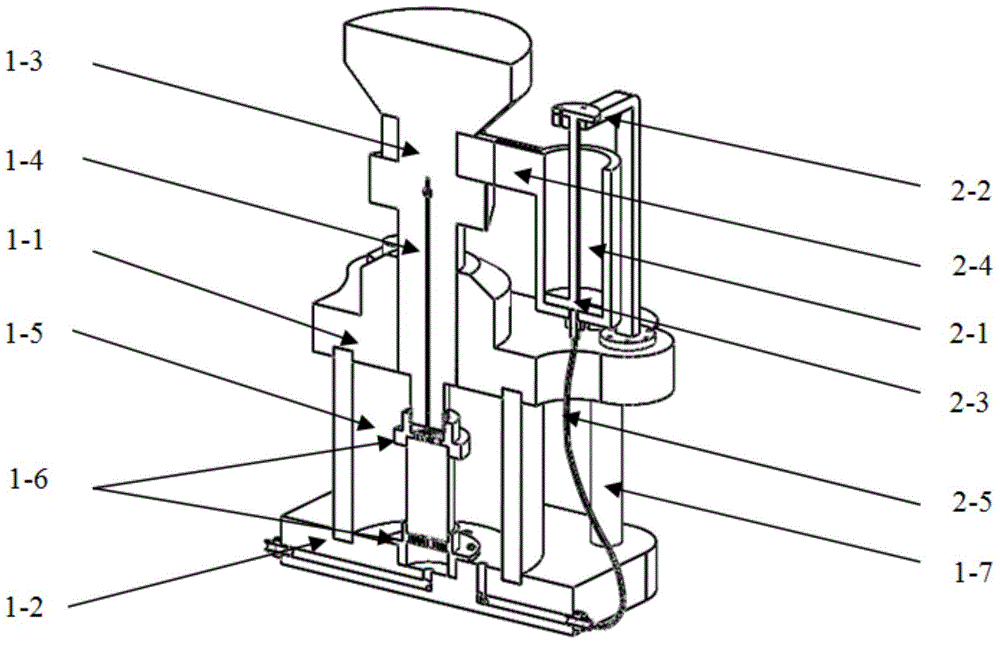

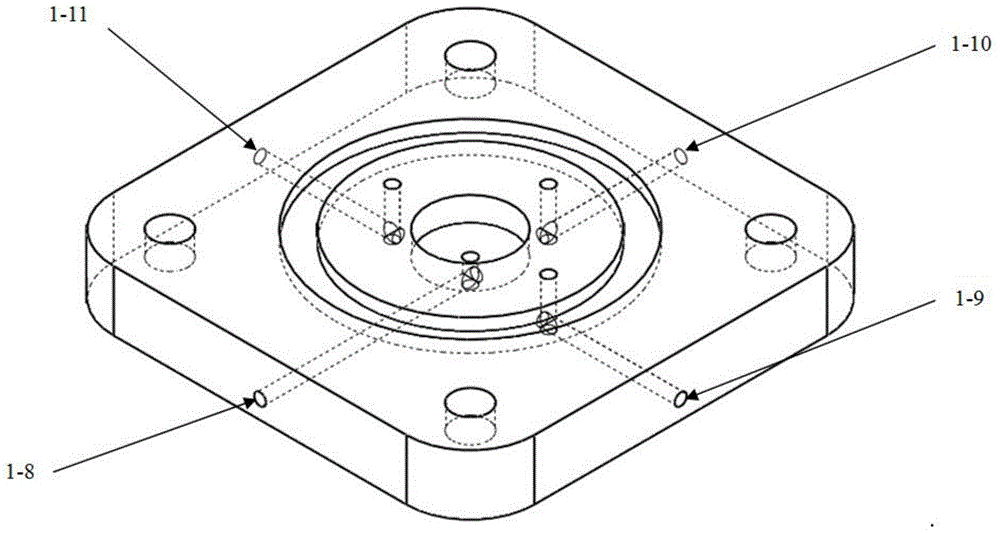

[0070] Such as figure 1 Shown: A constant-volume gas-solid coupling physical-mechanical parameter test device system includes a visual loading system 1, a constant volume system 2, and an atmospheric pressure visual gas volume measurement system 3; the visual loading system 1 can realize quantitative inflation of the test piece , three-axis pressurization and pressure relief, and the visual real-time monitoring function of the whole process; the constant volume system 2 can realize the constant volume of the axial pressurization process to eliminate the interference of the pressure change on the test process; the normal pressure visual gas volume measurement system 3 uses communication The principle of the device and the quantitative drainage method can realize the quantitative unloading of the confining pressure and the visual monitoring of the adsorpt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com