Operating mechanism limiting structure based on magnetic suspension technology

A technology of operating mechanism and limit structure, applied in the direction of contact drive mechanism, etc., can solve the problems of increasing hidden safety hazards, large module occupied space, increasing the size of the operating mechanism, etc. Avoid the effect of misuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] Further detailed description will be made below in conjunction with accompanying drawing and invention:

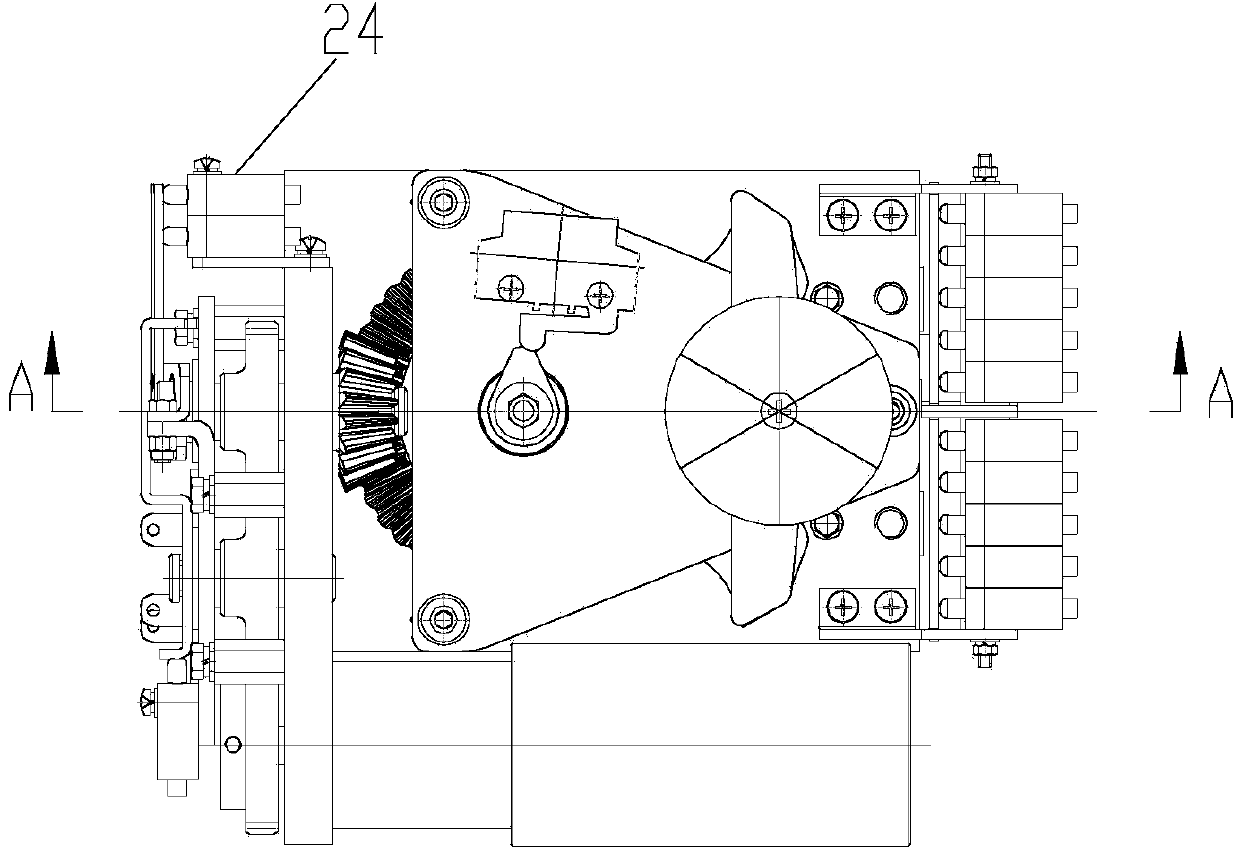

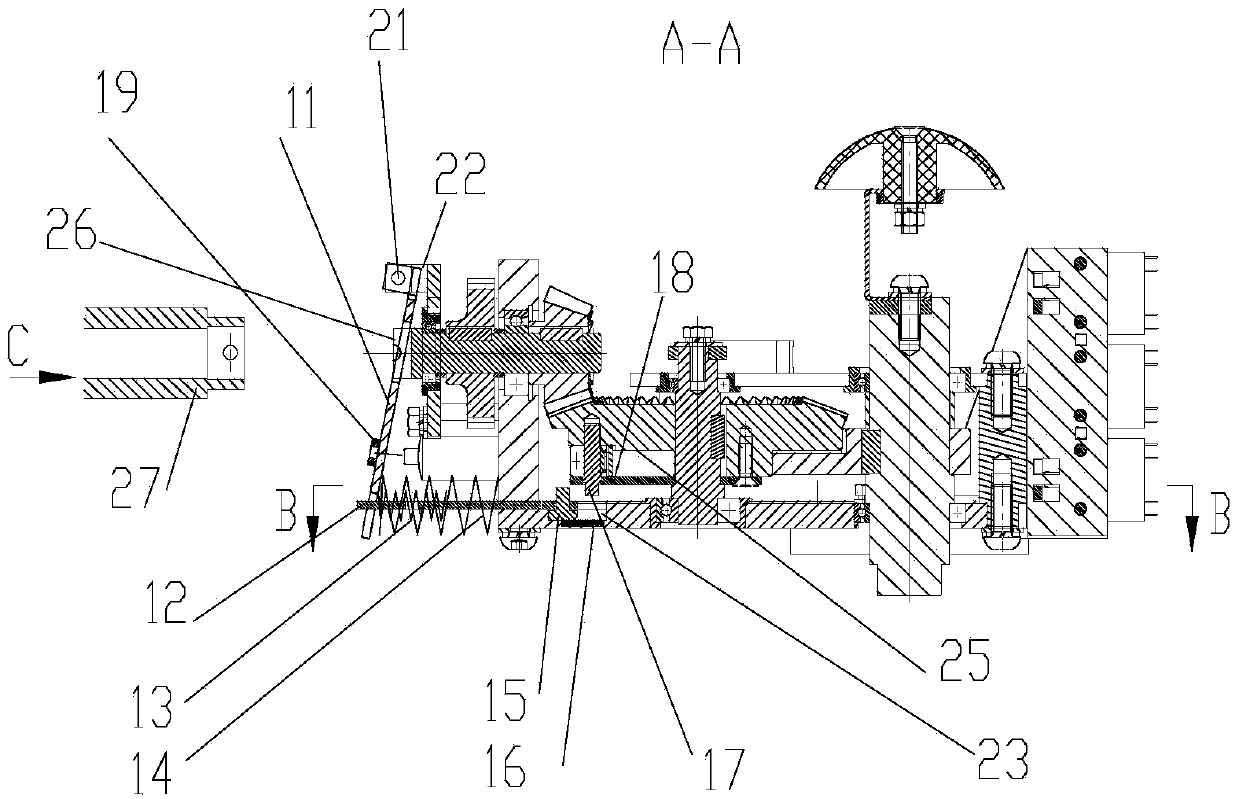

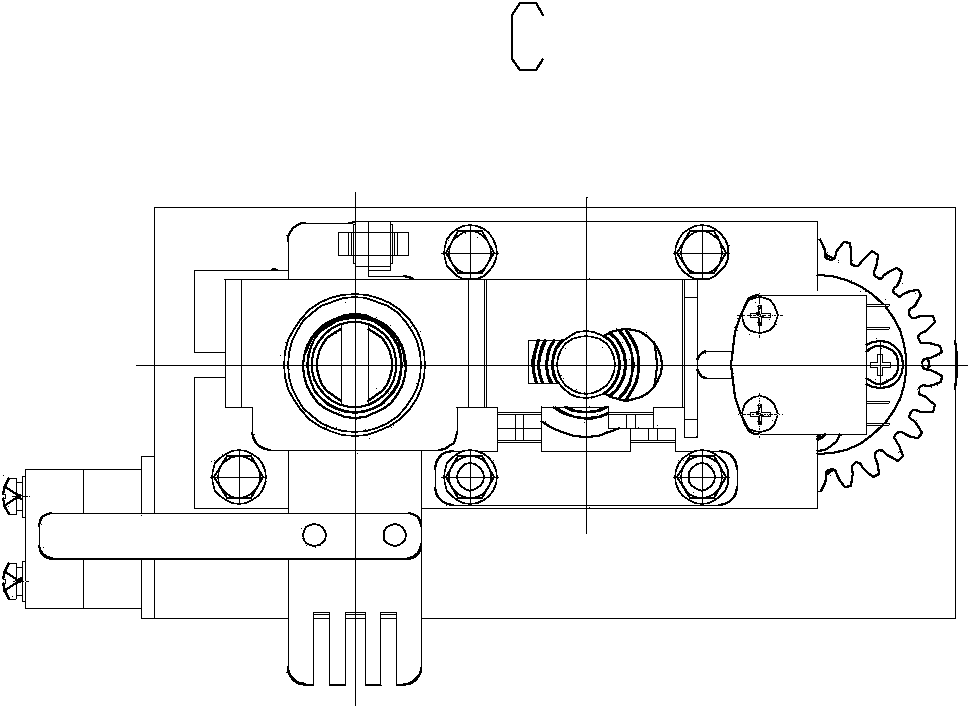

[0058] See Figure 1- Figure 19 , which is an embodiment in which the limit structure based on magnetic suspension technology of the present invention is applied to the GIS three-position switch operating mechanism. The operating mechanism includes a horizontal rotating part and is located in a housing. On the base 23, there are three layers of groove cavities: referring to Fig. 11, the bottom one is a small long rectangular groove or hole 31, in which a guiding permanent magnet 16 of the same shape is fixed; the middle one is a large long rectangular groove 32, one of its long ends is deformed into a triangular groove; the uppermost is a T-shaped groove 33, and its long end extends to the side of the base 23; the long axes of the three grooves coincide; The stop block 15 corresponds to the three-layer groove cavity when turning.

[0059] Also included are:

[0060...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com