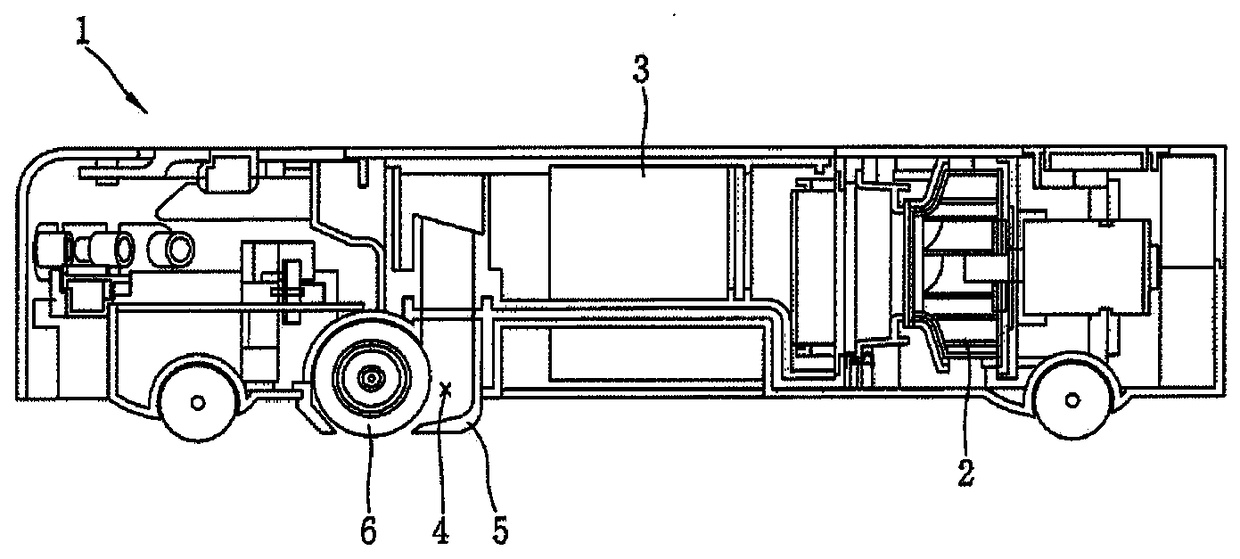

Robotic vacuum cleaner and dust detection method thereof

A robot vacuum cleaner, dust technology, applied in the direction of vacuum cleaners, robot cleaning machines, chemical instruments and methods, etc., can solve the problems of increased energy consumption of the suction motor 2, obstruction of the air flow path, and decline in the suction performance of the suction motor 2, so as to prevent suction The effect of performance degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

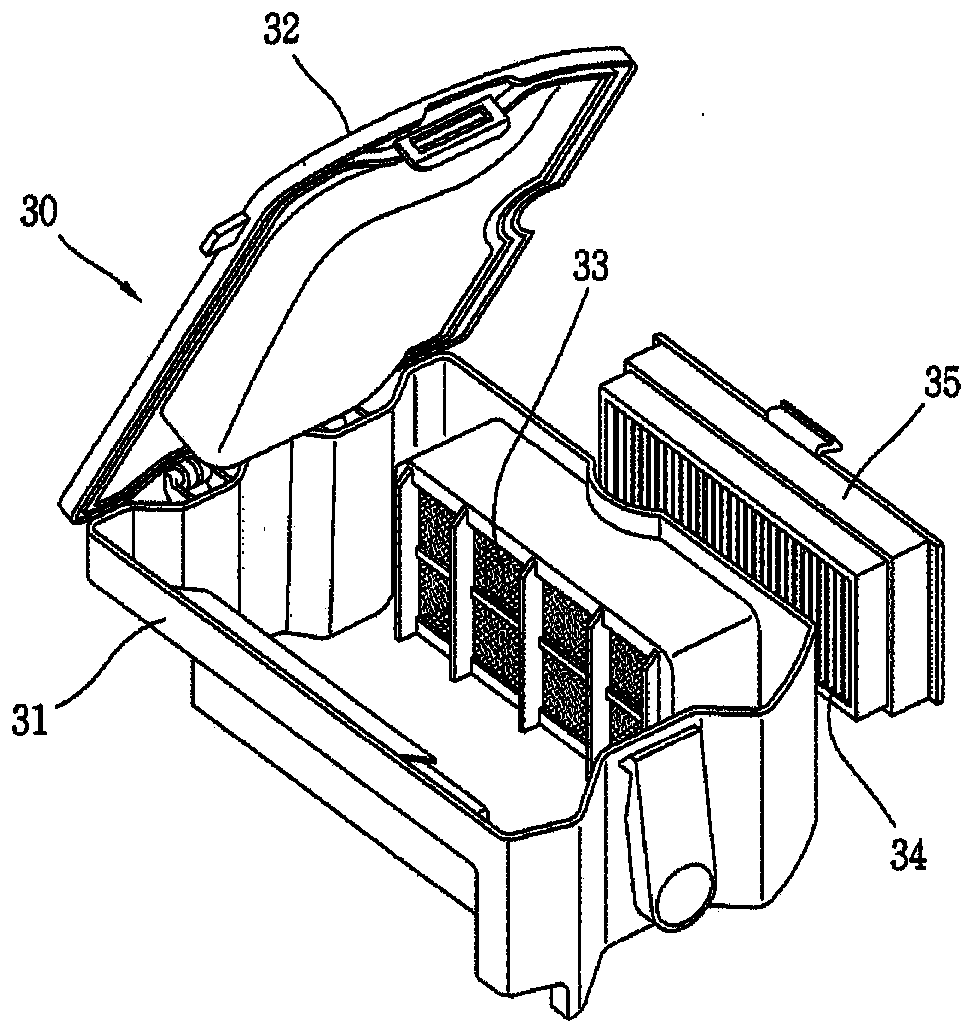

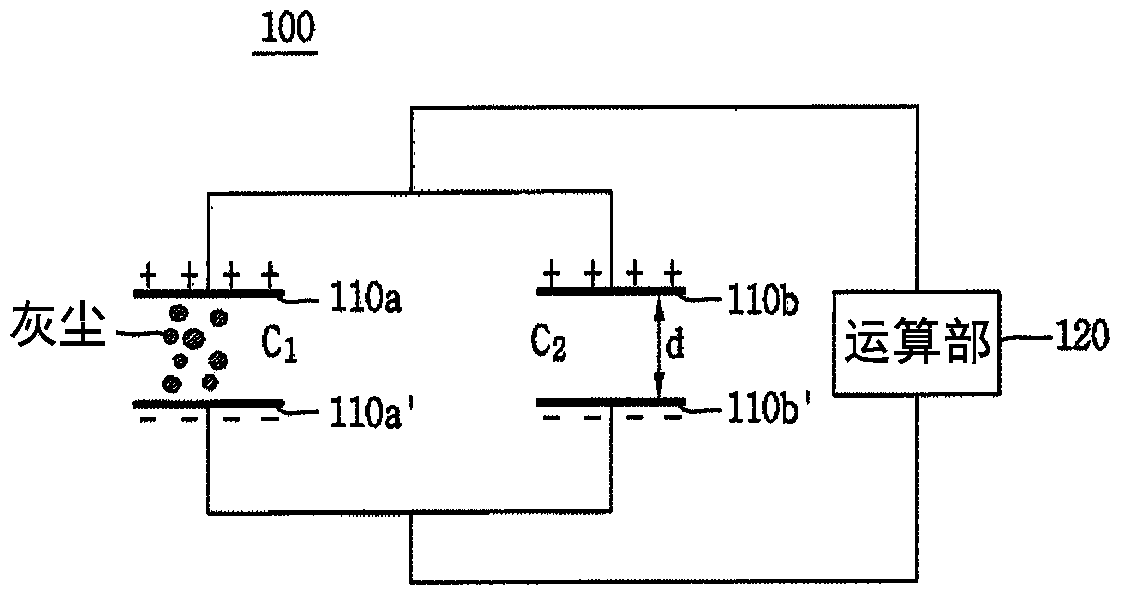

[0048]Hereinafter, the embodiments disclosed in this specification will be described in detail with reference to the drawings, and the same or similar constituent elements will be assigned the same reference numerals regardless of the reference numerals, and redundant descriptions will be omitted. The suffixes "module" and "part" related to the structural elements used in this specification are given or mixed for the convenience of formulating the specification, and they themselves do not have different meanings or functions. In describing the embodiments disclosed in this specification, In the process, when it is judged that the detailed description of related known technologies may make the gist of the embodiments disclosed in this specification unclear, the detailed description will be omitted. Moreover, it should be noted that the accompanying drawings are only for easier understanding of the embodiments disclosed in this specification, and should not be construed as limiti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com