A method of painting enamel on purple sandware

A technology of purple sand ware and purple sand, applied in the field of purple sand ware manufacturing, can solve the problems of difficult to achieve decorative performance effect, dark color, dull appearance, etc., and achieve the effect of enriching ornamental and collection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

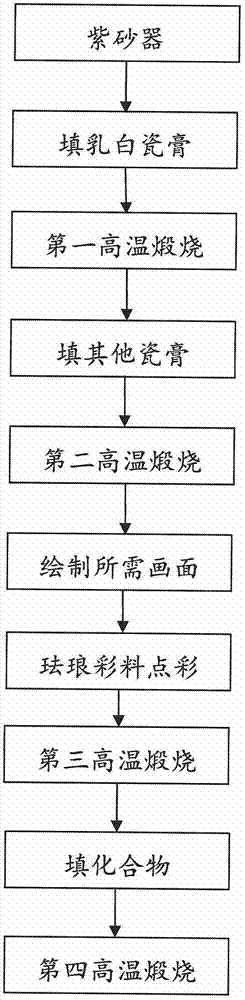

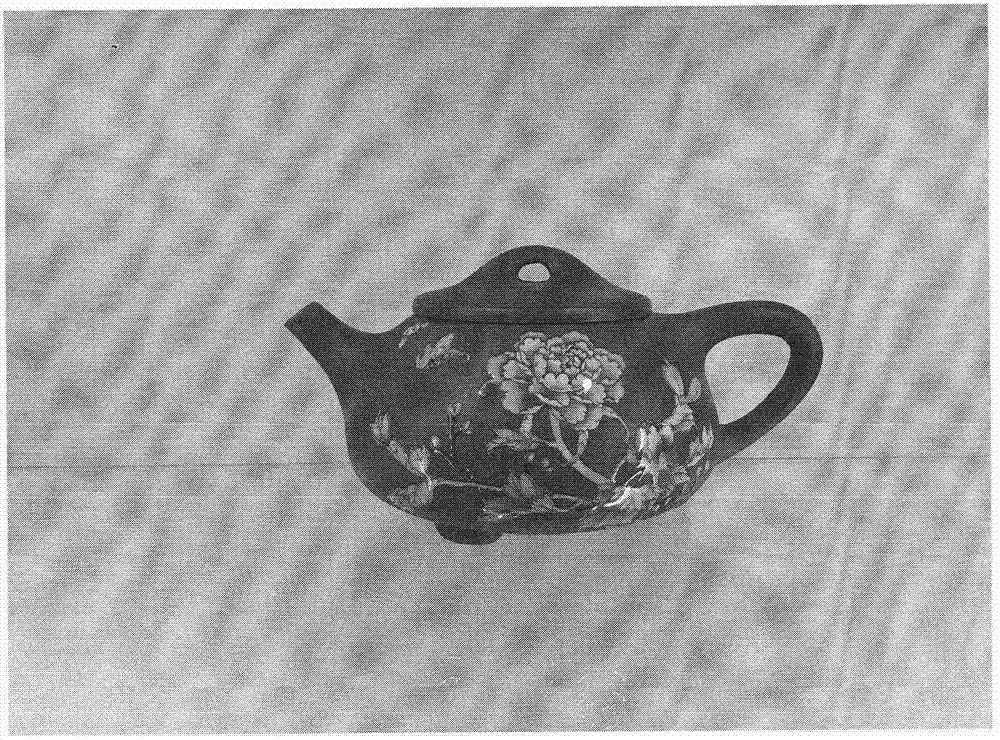

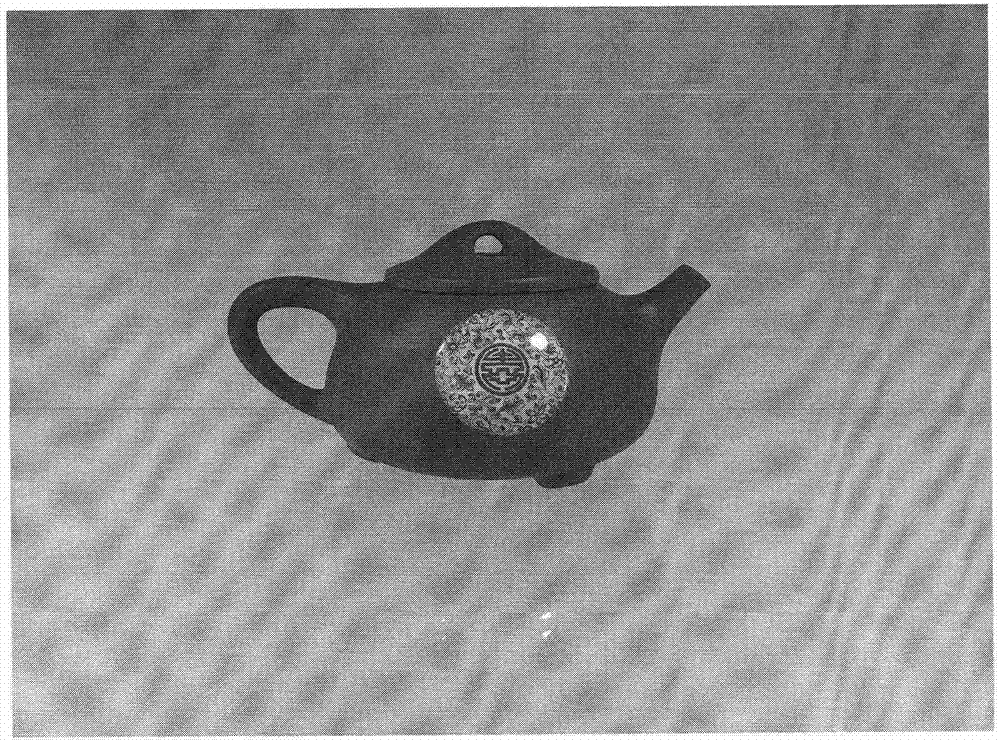

[0033] Taking the purple sand teapot as an example, the manufacturing method is explained in detail.

[0034] Such as figure 1 As mentioned above, first wash the teapot with a damp cloth and let it cool slightly.

[0035] Prepare a milky white porcelain paste, fill it with a thin layer, and carry out high-temperature (780-800°C) calcination.

[0036] Fill it again with other porcelain paste (glass white is optional), and perform the second calcination. The temperature of this calcination is 10°C higher than that of the first time.

[0037] Draw the desired screen.

[0038] Apply stippling with enamel color.

[0039] Baking in a high-temperature furnace, this time is 10-15°C higher than the temperature of the previous calcination.

[0040] Fill in the glass white again to make the picture bright and beautiful.

[0041] Carry out high-temperature calcination to produce finished products, and the temperature of this calcination is 10-15 ℃ higher than that of the previous cal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com