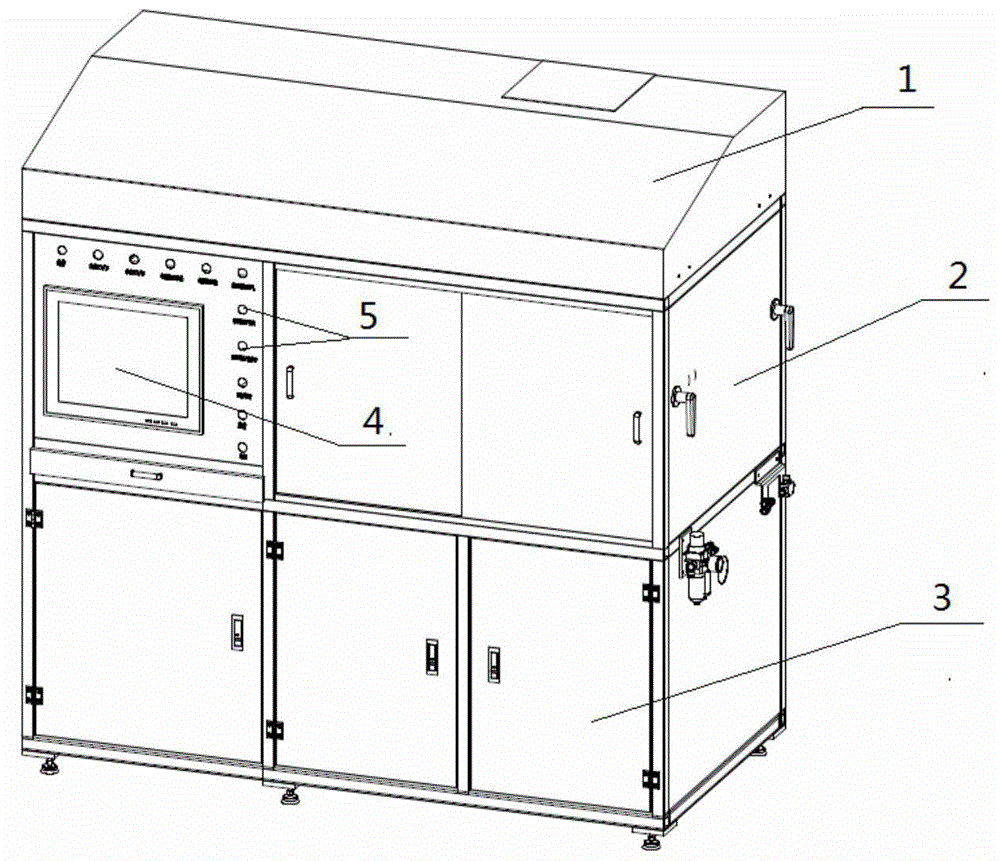

Digital fully-automatic railway wagon bearing sign plate marking machine

A technology for railway wagons and sign boards, applied to typewriters, printing devices, printing, etc., can solve problems such as ambiguity, irregular character spacing, and low marking efficiency, and achieve consistent font depth and character spacing. Neat and fast marking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in combination with specific embodiments, but this does not constitute a limitation to the protection scope of the present invention.

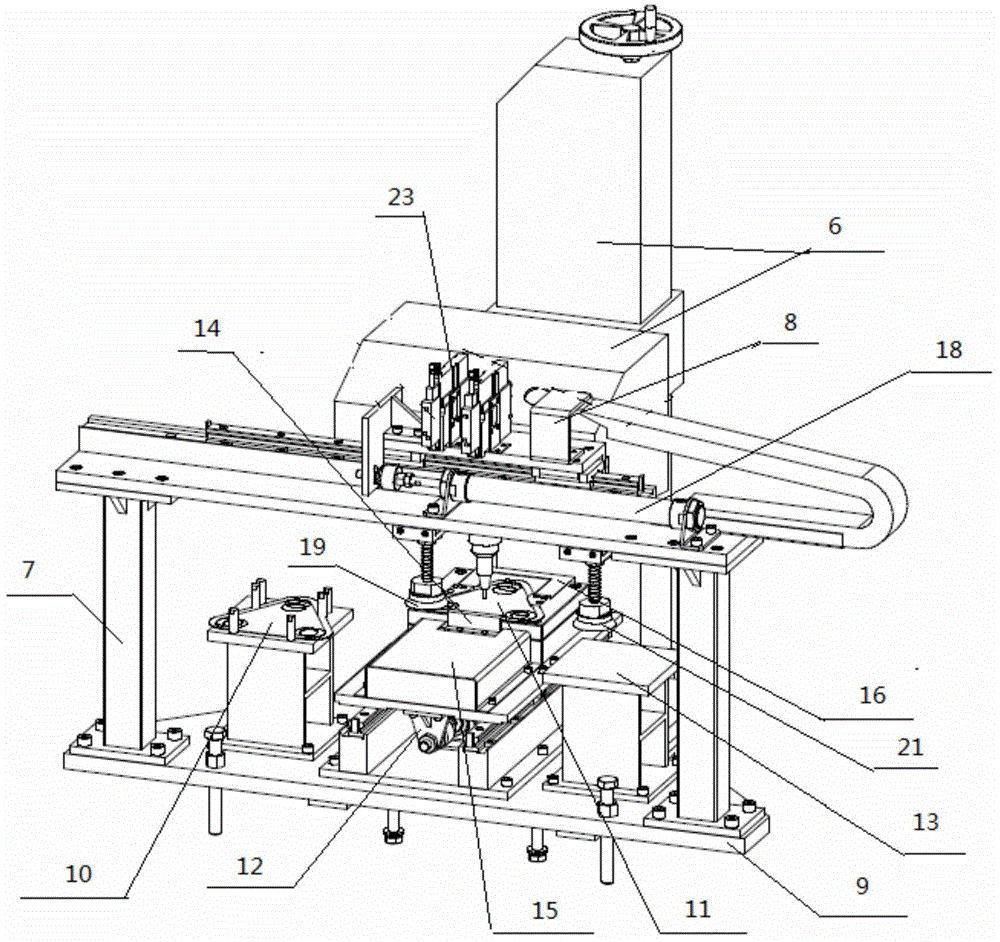

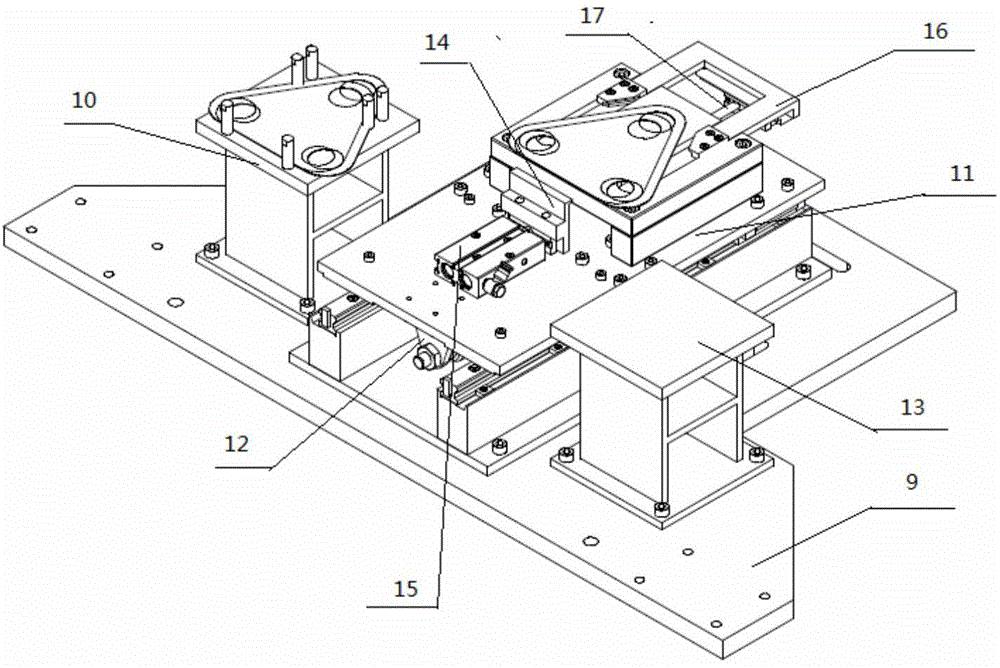

[0017] The digital full-automatic marking machine for bearing signs of railway wagons mainly includes: the support 7 installed in front of the pneumatic marking machine 6, the pneumatic mechanism 8 can slide left and right on the top of the support 7, the first cylinder 18 is installed on the support 7 and connected with the pneumatic The mechanism 8 is connected to make the pneumatic mechanism 8 slide left and right; the bottom of the bracket 7 is provided with a base 9 on which the marking table 11 can slide back and forth, and the second cylinder 12 is connected to the marking table 11 for making the marking table 11 Move back and forth; one side of the marking table 11 is the feeding table 10, above the feeding table 10 there is a feeding vacuum suction cup 19, the third cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com