Method for preparing graphene/silver/titanium dioxide composite material

A composite material, titanium dioxide technology, applied in the fields of botanical equipment and methods, chemicals for biological control, animal repellants, etc., can solve problems such as complex use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

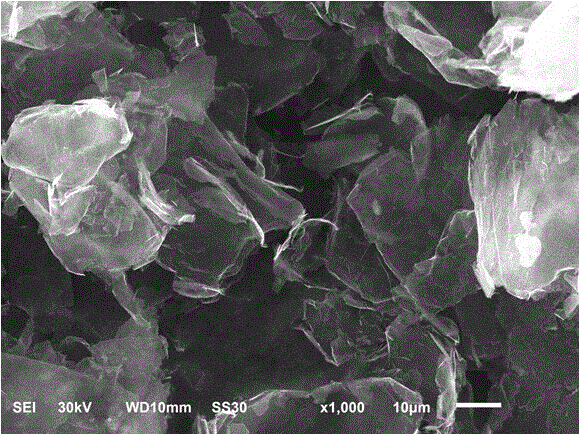

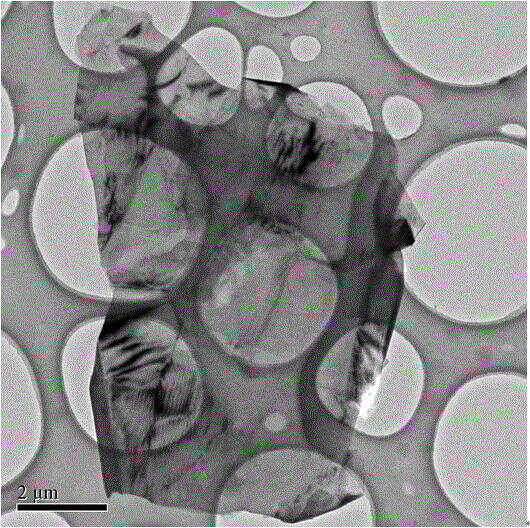

[0028] (1) Weigh 1g of graphene flakes and 2g of PVP powder, transfer the two powders into a three-hole flask, then measure 200 ml of deionized water, ultrasonically disperse in a 200 W ultrasonic cleaning machine, and adjust the mechanical stirrer The rotation speed is 200 rpm, and the ultrasonic wave is about 40 min to obtain a stable aqueous solution of graphene sheets. figure 1 is the SEM image of the graphene sheet in the experiment, figure 2 is a TEM image of a graphene sheet.

[0029] (2) Weigh 1g of silver nitrate powder and add it to the graphene sheet solution in (1), fix the three-hole flask in a constant temperature oil bath, raise the temperature to 82°C and keep the temperature constant for 10 minutes, and adjust the speed of the mixer to 150 rpm , and then measure about 3 ml of hydrated N 2 h 4 Put the solution in a constant pressure funnel, adjust the dripping speed to 0.5 drops / second, and wait for the hydrated N 2 h 4 After the solution was added dropwi...

Embodiment 2

[0032] (1) Weigh 1.5 g of graphene flakes and 2 g of SDS powder, transfer the two powders into a three-hole flask, then measure 150 ml of deionized water, ultrasonically disperse them in a 200 W ultrasonic cleaning machine, and adjust The rotation speed of the mechanical stirrer was 200 rpm, and a stable aqueous solution of graphene sheets was obtained by ultrasonication for about 30 min.

[0033] (2) Weigh 1g of silver nitrate powder and add it to the graphene sheet solution in (1), fix the three-hole flask in a constant temperature oil bath, raise the temperature to 85°C and keep the temperature constant for 10 minutes, and adjust the speed of the mixer to 150 rpm , and then measure about 2.5 ml of NaBH 4 Put the aqueous solution in a constant pressure funnel, adjust the dripping speed to 0.5 drops / second, and wait for the NaBH to be hydrated 4 After the aqueous solution was added dropwise, the temperature was kept at the reaction temperature for 2 hours to obtain a uniform...

Embodiment 3

[0036] (1) Weigh 2 g of graphene flakes and 2 g of PVP powder, transfer the two powders into a three-hole flask, then measure 300 ml of deionized water, ultrasonically disperse them in a 250 W ultrasonic cleaning machine, and adjust The rotation speed of the mechanical stirrer was 250 rpm, and a stable aqueous solution of graphene sheets was obtained by ultrasonication for about 25 min.

[0037] (2) Weigh 1.5 g of silver nitrate powder and add it to the graphene sheet solution in (1), fix the three-hole flask in a constant temperature oil bath, raise the temperature to 80°C and keep the temperature constant for 10 minutes, and adjust the speed of the mixer to 150 rpm, then measure about 5 ml of vitamin C aqueous solution in the constant pressure funnel, adjust the dripping speed to 1 drop / second, after the hydrated vitamin C aqueous solution is added dropwise, keep the temperature at the reaction temperature for 3 hours to obtain uniform graphite olefin / silver composite soluti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com