Adjustable automatic stacker and control method for row corrugated paper

A corrugated paper and columnar technology, which is applied in the stacking of objects, de-stacking of objects, conveyors, etc., can solve the problems of manual stacking and scraping of corrugated paper stacks, achieve neatness, improve mutual coordination and cooperation, use wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

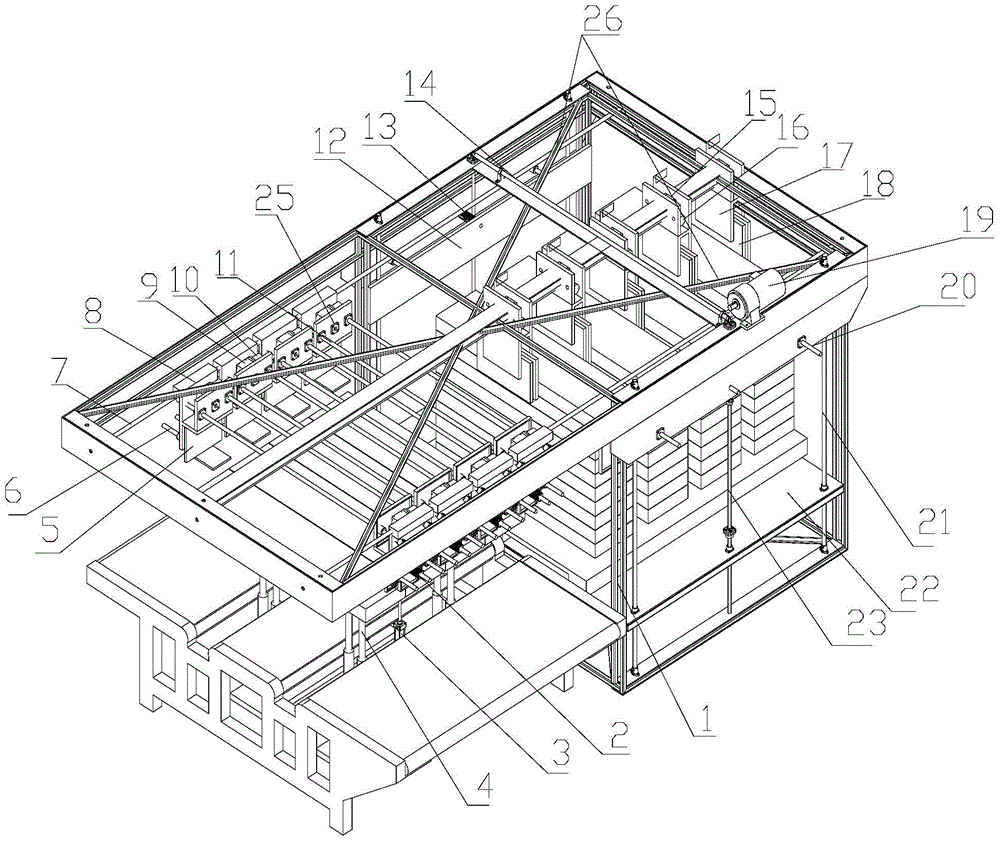

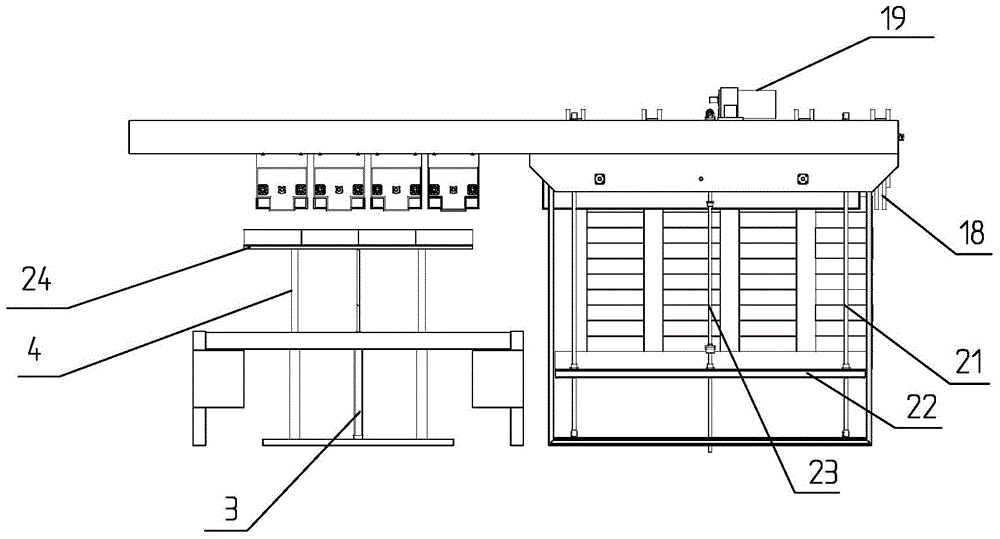

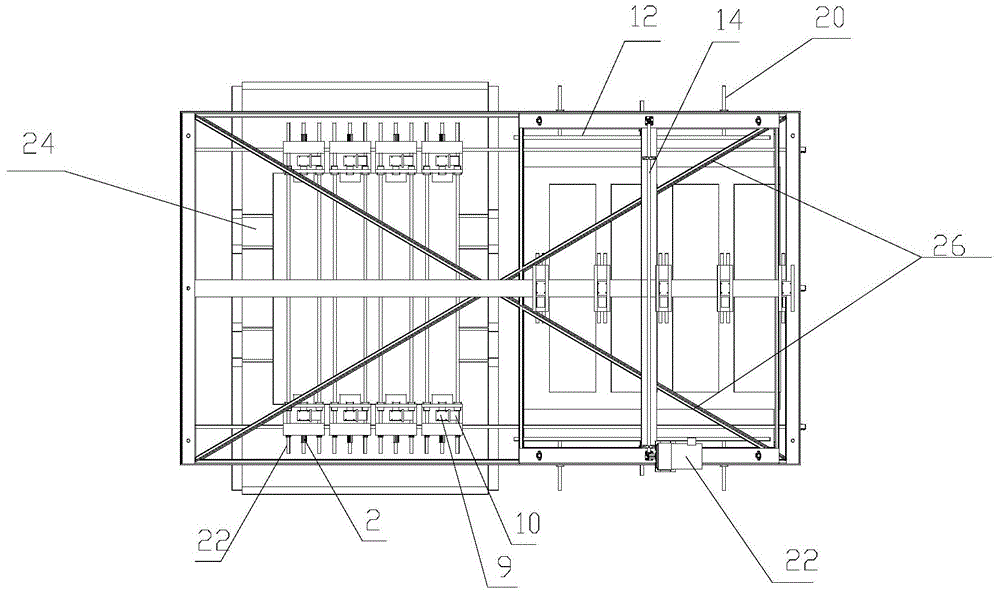

[0038] This embodiment provides an adjustable fully automatic stacker for split-type corrugated paper. The stacker is composed of a lifting device, a feeding device and a feeding device. After the height is reached, the retrieving device picks up the material and transports it to the stacking position. After the material is put down, the beating device gently pats the material horizontally and vertically to realize the whole process of the material.

[0039] Such as figure 1 , figure 2 , image 3As shown, an adjustable automatic stacker for split-type corrugated paper in this embodiment includes: a base 1, a first cylinder 2, a second cylinder 3, a first guide rod 4, a stripper plate 5, a first Two guide rods 6, the third guide rod 7, the feeding plate 8, the first reducer 9, the first motor 10, the fourth guide rod 11, the first clapping plate 12, the third cylinder 13, the transmission rod 14, the first Second reducer 15, second motor 16, connecting block 17, second clap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com