Automatic filling device with uniform stirring function

An automatic filling and functional technology, which is applied in the direction of mixers with rotating stirring devices, packaging, transportation and packaging, etc., can solve the problems affecting the accuracy, reliability and degree of automation of filling devices, positioning reliability and accuracy. Problems such as high height and complex structure of the conveying part

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

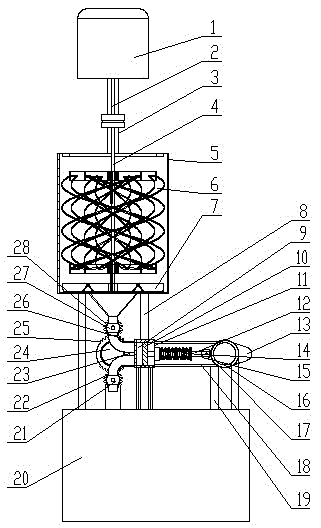

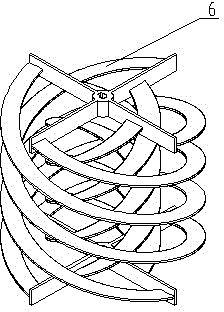

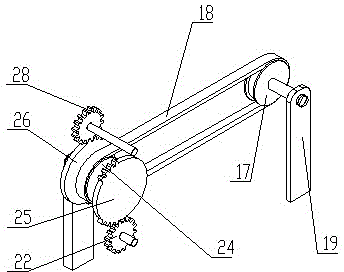

[0023] The specific implementation, structure, features and efficacy of the automatic filling device with stirring function according to the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

[0024] see Figure 1 to Figure 7 , the automatic filling device with stirring function of the present invention includes a power assembly 1, a stirring structure 3, a material feeding structure 9, and a transmission reversing structure 23, the lower end of the power assembly 1 is connected with the stirring structure 3 through a transmission shaft 2, and the stirring structure The stirring shaft 4 of 3 is located in the material box 5, the stirring shaft 4 is provided with the stirring paddle 6, the lower part of the material box 5 is connected with the feeding structure 9, the feeding structure 9 is connected with the transmission reversing structure 23, the piston of the feeding structure 9 One end of the cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com