a gas turbine engine

A technology of gas turbines and turbines, which is applied in the field of turbines and can solve problems such as poor aerodynamic performance of turbines, complicated connection of turbine disks at all levels, and large changes in the inner diameter of rotor turbine disks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

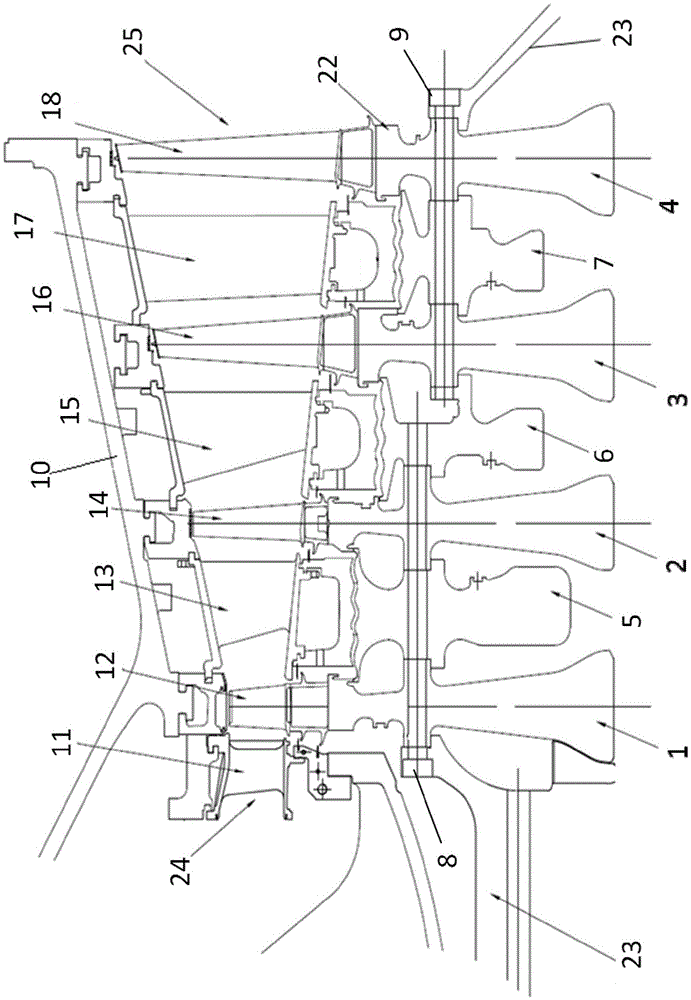

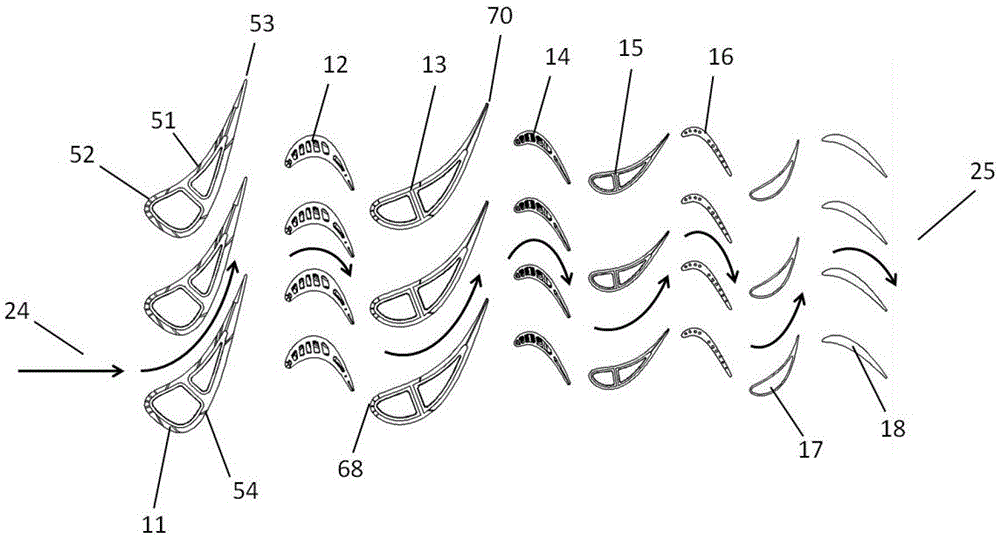

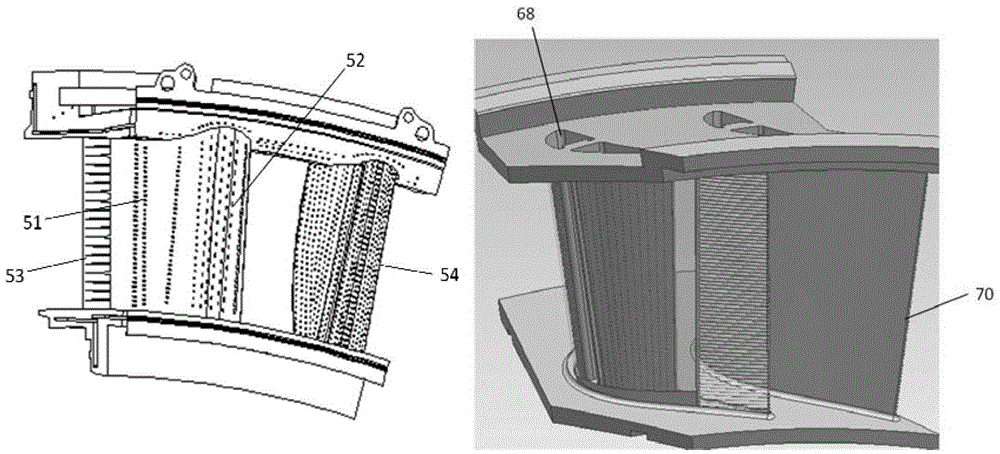

[0030] figure 1 is a cross-sectional view of the upper half of a turbine according to an embodiment of the present invention, such as figure 1 As shown, the turbine includes a casing 10, a turbine inlet 24, a turbine outlet 25, a turbine rotor 22, four-stage vanes 11, 13, 15 and 17, and four-stage moving blades 12, 14, 16 and 18, of which:

[0031] The turbine inlet 24 is located at one end of the turbine as an inlet for high-temperature gas;

[0032] The turbine outlet 25 is located at the other end of the turbine, as the outlet of high-temperature gas;

[0033] The stator blades of the four-stage vanes 11, 13, 15 and 17 are installed on the fixed casing 10 in sequence, and the moving blades of the four-stage rotor bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com